Department of Natural Resources and Environmental Control

Division of Air Quality

FINAL

Secretary’s Order No.: 2012-A-0040

Date of Issuance: November 9, 2012

Effective Date of the Amendment: December 11, 2012

Under the authority vested in the Secretary of the Department of Natural Resources and Environmental Control (“Department” or “DNREC”) the following findings, reasons and conclusions are entered as an Order of the Secretary in the above-referenced rulemaking proceeding.

Background and Procedural History

This Order considers the proposed regulatory amendments to 7 DE Admin. Code 1120, New Source Performance Standards, to repeal of Section 29, “Standards of Performance for Hospital/Medical/Infectious Waste Incinerators”.

On September 15, 1997, the EPA adopted a New Source Performance Standard and Emission Guideline at 40 CFR Part 60, Subparts Ec and Ce, which were applicable to both new and existing hospital, medical, and infectious waste incinerator (HMIWI) units, respectively. At the same time, the EPA published a related emissions guideline to assist the States in developing their “Section 129 Plan” for existing sources under 40 CFR Part 60 Ce. EPA’s September 15, 1997 promulgation called for Delaware to submit its “Section 129 Plan” within one year.

Over the next twelve months, the Department determined that there were three HMIWI units in Delaware: The DuPont Experimental Station in Wilmington; Kent General Hospital in Dover; and Nanticoke Memorial Hospital in Seaford. DNREC then drafted its proposed Section 29 of Regulation 1120, as well as its “Section 129 Plan”, and conducted both a public workshop and public hearing regarding this matter. As required under the Clean Air Act, Delaware subsequently adopted Section 29, “Standards of Performance for Hospital/Medical/Infectious Waste Incinerators” into Regulation 1120 on September 1, 1998. Accordingly, the Department submitted its “Section 129 Plan” to the EPA, and EPA approved Delaware’s plan on April 14, 2000.

In 2007, the EPA completed its review for its aforementioned hospital, medical and infectious waste incinerator regulation, and determined that revisions to the same were warranted. In October of 2009, the EPA revised the New Source Performance Standard applicable to newly-built sources and published a revised emissions guideline for existing sources to assist the States in revising their “Section 129 Plan”. Once again, EPA’s revision to its emissions guideline called for Delaware to submit its revised “Section 129 Plan” within one year.

Upon the Department’s review of its “Section 129 Plan”, DNREC found that the three existing sources referenced above had since shut down and dismantled their incinerators, and that no newly-built hospital, medical or infectious waste incinerators had been installed. Thus, it was unnecessary to revise Delaware’s “Section 129 Plan”. On June 17, 2010, the Department submitted a request to EPA Region 3 to have Delaware’s “Section 129 Plan” withdrawn, and on November 30, 2010, the EPA formally withdrew Delaware’s plan.

Delaware is now proposing to repeal Section 29 of Regulation 1120, as its inherent regulatory requirements are currently outdated, and its continuance is no longer justified, due to the fact that there is no hospital, medical or infectious waste incinerator in Delaware that are subject to it. Should a facility wish to construct a new HMIWI unit in the future, such installation would be regulated under the amended 40 CFR Part 60, Subpart Ec, which EPA formally adopted on October 6, 2009.

The Department’s Division of Air Quality commenced the regulatory development process with Start Action Notice 2012-10. The Department published the proposed regulatory amendment in the August 1, 2012 Delaware Register of Regulation and held a public hearing on August 22, 2012. The Department’s presiding hearing officer, Lisa A. Vest, prepared a Hearing Officer’s Report dated October 9, 2012 (Report). The Report recommends certain findings and the adoption of the proposed Amendment as attached to the Report as Appendix A.

Findings and Discussion

I find that the proposed Amendment is well-supported by the record developed by the Department, and adopt the Report to the extent it is consistent with this Order. The Department’s experts developed the record and drafted the proposed Amendment. As noted in the aforementioned Hearing Officer’s Report, no members of the public attended the aforementioned hearing on August 22, 2012, nor were any comments received from the public by the Department, either at the time of the hearing or prior to the record formally closing in this matter on September 6, 2012.

I find that the Department’s experts in the Division of Air Quality fully developed the record to support adoption of these Amendments. Promulgation of the aforementioned proposed amendment to 7 DE Admin. Code 1120 will repeal Section 29, as its inherent regulatory requirements are currently outdated, and its continuance is no longer justified, due to the fact that there is no hospital, medical or infectious waste incinerator in Delaware subject to it. Should a facility wish to construct a new HMIWI unit in the future, such installation would be regulated under the amended 40 CFR Part 60, Subpart Ec, which EPA formally adopted on October 6, 2009.

In conclusion, the following findings and conclusions are entered:

1.) The Department has jurisdiction under its statutory authority to issue an Order adopting these proposed Amendments as final;

2.) The Department provided adequate public notice of the proposed Amendment, and provided the public with an adequate opportunity to comment on the proposed Amendment, including at a public hearing;

3.) The Department held a public hearing on the proposed Amendment on August 22, 2012;

4.) The Department’s Hearing Officer’s Report, including its recommended record and the recommended Amendment as set forth in Appendix A, are adopted to provide additional reasons and findings for this Order;

5.) The recommended Amendment does not reflect any change from the proposed regulation Amendment as published in the August 1, 2012, Delaware Register of Regulations;

6.) Promulgation of the aforementioned proposed amendment to 7 DE Admin. Code 1120 will repeal Section 29, as its inherent regulatory requirements are currently outdated, and its continuance is no longer justified, due to the fact that there is no hospital, medical or infectious waste incinerator in Delaware subject to it. Should a facility wish to construct a new HMIWI unit in the future, such installation would be regulated under the amended 40 CFR Part 60, Subpart Ec, which EPA formally adopted on October 6, 2009; and

7.) The Department shall submit this Order approving the final regulation to the Delaware Register of Regulations for publication in its next available issue, and provide such other notice as the law and regulation require and the Department determines is appropriate.

Collin P. O’Mara, Secretary

1120 New Source Performance Standards

12/07/1988

1.1 Applicability. The provisions of this regulation apply to any person responsible for any stationary sources specified herein the construction, reconstruction or modification of which was commenced after August 17, 1971.

1.2 Notification and Record Keeping

1.2.1 Any person subject to the provisions of this regulation shall furnish the Secretary written notification as follows:

1.2.1.1 A notification of the anticipated date of initial startup of an applicable source not more than 60 days nor less than 30 days prior to such date.

1.2.1.2 A notification of the actual date of initial startup of an applicable source within 15 days after such date.

1.2.1.3 A notification of the date construction or reconstruction of an applicable source is commenced postmarked no later than 30 days after such date. This requirement shall not apply in the case of mass-produced facilities, which are purchased in completed form.

1.2.1.4 A notification of any physical or operational change to an existing facility, which may increase the emission rate of any air pollutant to which a standard applies, unless that change is specifically exempted under an applicable provision. This notice shall be postmarked 60 days or as soon as practicable before the change is commenced and shall include information describing the precise nature of the change, present and proposed emission control systems, productive capacity of the facility before and after the change, and the expected completion date of the change. The Secretary may request additional relevant information subsequent to this notice.

1.2.1.5 A notification of the date upon which demonstration of the continuous monitoring system performances commences. Notification shall be postmarked not less than 30 days prior to such date.

1.2.2 Any owner or operator subject to the provisions of 1.0 of this regulation shall maintain records of the occurrence and duration of any startup, shutdown, or malfunction in the operation of an applicable source; any malfunction of the air pollution control equipment; or any periods during which a continuous monitoring system or monitoring device is inoperative.

1.2.3 Each owner or operator required to install a continuous monitoring system shall submit a written report of excess emissions (as defined in applicable provisions) to the Secretary for every calendar quarter. All quarterly reports shall be postmarked by the 30th day following the end of each calendar quarter and shall include the following information:

1.2.3.1 The magnitude of excessive emissions, any conversion factor or factors used, and the date and time of commencement and completion of each time period of excess emissions.

1.2.3.2 Specific identification of each period of excess emissions that occurs during startups, shutdowns, and malfunctions of the applicable source. The nature and cause of any malfunction (if known), the corrective action taken or preventative measures adopted.

1.2.4 Any owner or operator subject to the provisions of 1.0 of this regulation shall maintain a file of all measurements including continuous monitoring system, monitoring device, and performance testing measurements; all continuous monitoring system performance evaluations; all continuous monitoring system or monitoring device calibration checks; adjustments and maintenance performed on these systems or devices; and all other information required by 1.0 of this regulation recorded in a permanent form suitable for inspection. The file shall be retained for at least two years following the date of such measurements, maintenance, reports, and records.

1.3 Monitoring Requirements

1.3.1 Unless otherwise approved by the Secretary or specified in applicable provisions, the requirements of 1.0 of this regulation shall apply to all continuous monitoring systems required under applicable provisions of this regulation.

1.3.2 All continuous monitoring systems and monitoring devices shall be installed and operational prior to conducting performance tests under 1.4 of this regulation. Verification of operational status shall, as minimum, consist of the following:

1.3.2.1 Completion of the conditioning period specified by applicable requirements.

1.3.2.2 For monitoring devices referenced in applicable provisions of this regulation, completion of the manufacturer's written requirements or recommendations for checking the operation or calibration of the device.

1.3.3 During any performance tests required under 1.4 of this regulation or within 30 days thereafter and at such other times as may be required by the Secretary, the person responsible for any applicable source shall conduct continuous monitoring system performance evaluations and furnish the Secretary within 60 days thereof a written report of the results of such tests. These continuous monitoring system performance evaluations shall be conducted in accordance with the following specifications and procedures:

1.3.3.1 Continuous monitoring systems for measuring opacity of emissions shall comply with Performance Specification 1.

1.3.3.2 Continuous monitoring systems for measuring nitrogen oxides emissions shall comply with Performance Specification 2.

1.3.3.3 Continuous monitoring systems for measuring sulfur dioxide emissions shall comply with Performance Specification 2.

1.3.3.4 Continuous monitoring systems for measuring the oxygen content or carbon dioxide content of effluent gases shall comply with Performance Specification 3.

1.3.4 Performance specifications of 1.0 of this regulation are synonymous with those set forth in Appendix B, 40 CFR 60, dated July 1, 1982, which are hereby adopted by reference with the word substitution "Secretary" for "Administrator".

1.3.5 Calibration checks and zero and span adjustments and reporting of data on all continuous monitoring equipment shall be in accordance with methods approved by the Department. Such methods shall as a minimum, comply with Subsection 60.13(d) in 40 CFR 60, dated July 1, 1982, which is hereby adopted by reference with the word substitution "Secretary" for "Administrator".

1.3.6 When the effluents from a single applicable source or two or more applicable sources subject to the same emission standards are combined before being released to the atmosphere, the person may, subject to approval by the Secretary install applicable continuous monitoring systems on each effluent, but otherwise shall install such systems on the combined effluent. When the applicable sources are not subject to the same emission standards, separate continuous monitoring systems shall be installed on each effluent. When the effluent from one applicable source is released to the atmosphere through more than one point, the person shall install applicable continuous monitoring systems on each separate effluent unless the installation of fewer systems is approved by the Secretary.

1.3.7

1.3.7.1 An owner or operator who, prior to September 11, 1974, entered into a binding contractual obligation to purchase specific continuous monitoring system components except as referenced by 1.3.7.1.3 of this regulation shall comply with the following requirements:

1.3.7.1.1 Continuous monitoring systems for measuring opacity of emissions shall be capable of measuring emission levels within +/- 20% with a confidence level of 95%.

1.3.7.1.2 Continuous monitoring systems for measurement of nitrogen oxides or sulfur dioxide shall be capable of measuring emission levels within +/- 20% with a confidence level of 95%.

1.3.7.1.3 Owners or operators of all continuous monitoring systems installed on an applicable source prior to October 6, 1975, are not required to conduct tests under 1.3.7.1.1 or 1.3.7.1.2 of this regulation unless requested by the Secretary.

1.3.7.2 All continuous monitoring systems referenced by 1.3.7.1 of this regulation shall be upgraded or replaced (if necessary) with new continuous monitoring systems, and such improved systems shall be demonstrated to comply with applicable performance specifications under 1.3.3 of this regulation by September 11, 1979.

1.3.8 Except for system breakdowns, repairs, calibration checks, and zero and span adjustments required herein, all continuous monitoring systems shall be in continuous operation and shall meet minimum frequency of operation requirements as follows:

1.3.8.1 All continuous monitoring systems referenced by 1.3.7.1 and 1.3.7.2 of this regulation for measuring opacity of emissions shall complete a minimum of one cycle of operation (sampling, analyzing and data recording) for each successive 10 second period.

1.3.8.2 All continuous monitoring systems referenced by 1.3.7.1 of this regulation for measuring oxides of nitrogen, sulfur dioxide, carbon dioxide, or oxygen shall complete a minimum of one cycle of operation (sampling, analyzing, and data recording) for each successive 15-minute period.

1.3.8.3 All continuous monitoring systems referenced by 1.3.7.2 of this regulation, except opacity shall complete a minimum of one cycle of operation (sampling, analyzing, and data recording) for each successive one-hour period.

1.3.9 All continuous monitoring systems or monitoring devices shall be installed such that representative measurements of emissions or process parameters from the applicable source are obtained. Additional procedures for location of continuous monitoring systems contained in the applicable Performance Specifications of this regulation shall be used.

1.3.10 Owners or operators of all continuous monitoring systems for measuring opacity shall reduce all data to 15-second averages. Consecutive 15-second averages, each less than the applicable standard may be recorded cumulatively. The 15-second averages in excess of the applicable standard shall be recorded for the time of occurrence. Any such averages in excess of the applicable standard shall be reported to the Department as excess emissions.

1.3.11 For systems other than opacity, one-hour averages shall be computed from four or more data points, equally spaced over each one-hour period. Data recorded during periods of system breakdown, repairs, calibration checks, and zero and span adjustments shall not be included in the data averages computed under 1.0 of this regulation. An arithmetic or integrated average of all data may be used. The data output of all continuous monitoring systems may be recorded in reduced or nonreduced form (e.g., ppm pollutant and percent O2 or lb/million BTU of pollutant). All excess emissions shall be converted into units of standard using the applicable conversion procedures specified in applicable provisions of this regulation. After conversion into units of the standard, the data may be rounded to the same number of significant digits used in applicable provisions of this regulation to specify the applicable standard (e.g., rounded to the nearest 1% opacity).

1.3.12 Upon written application by an owner or operator, the Secretary may approve alternatives to any monitoring procedures or requirements of 1.0 of this regulation including, but not limited to the following:

1.3.12.1 Alternative monitoring requirements when installation of continuous monitoring system or monitoring devices specified by 1.0 of this regulation would not provide accurate measurements due to liquid water or other substances interfering with the effluent gases.

1.3.12.2 Alternative monitoring requirements when the applicable source is infrequently operated.

1.3.12.3 Alternative monitoring requirements to accommodate continuous monitoring systems that require additional measurements to correct for stack moisture conditions.

1.3.12.4 Alternative locations for installing continuous monitoring systems or monitoring devices when the owner or operator can demonstrate that installation at alternative locations will enable accurate and representative measurements.

1.3.12.5 Alternative methods of converting pollutant concentration measurements to units of the standards.

1.3.12.6 Alternative procedures for performing daily checks of zero and span drift that do not involve use of span gases or test cells.

1.3.12.7 Alternative to the A.S.T.M. test methods or sampling procedures specified by any provision of this regulation.

1.3.12.8 Alternative continuous monitoring systems that do not meet the design or performance requirements in Performance Specification 1, but adequately demonstrate a definite and consistent relationship between its measurements and the measurements of opacity by a system complying with the requirements in Performance Specification 1. The Secretary may require that such demonstration be performed by each applicable source.

1.3.12.9 Alternative monitoring requirements when the effluent from a single applicable source or the combined effluent from two or more applicable sources are released to the atmosphere through more than one point.

1.4 Performance Tests

1.4.1 Within 60 days after achieving the maximum production rate at which the applicable source will be operated, but not later than 180 days after initial startup of such facility and at such other times as may be required by the Secretary, the person responsible for such source shall conduct performance test or tests and furnish the Secretary a written report of the results of such performance test or tests. The Department may conduct or contract for the conduct of a performance test whenever it concludes that such test is necessary to determine compliance.

1.4.2 Performance tests shall be conducted and data reduced in accordance with the test methods and procedures contained in each applicable provision unless the Secretary (1) specifies or approves, in specific cases, the use of a reference method with minor changes in methodology, (2) approves the use of an equivalent method, (3) approves the use of an alternative method the results of which he has determined to be adequate for indicating whether a specific source is in compliance, or (4) waives the requirement for performance tests because the owner or operator of a source has demonstrated by other means to the Secretary's satisfaction that the applicable source is in compliance with the standard.

1.4.3 Performance tests shall be conducted on representative performance of the applicable source. The Secretary may specify additional operating conditions to be tested. The person responsible for the applicable source shall make available to the Department a record of those operating parameters, which the Secretary determines appropriate to establish representative performance of the source. Operations during period of startup, shutdown, and malfunction shall not constitute representative conditions of performance tests unless otherwise specified in the applicable standard. The person responsible for an applicable source shall provide the Secretary 30 days prior notice of the performance test to afford the Secretary the opportunity to have an observer present.

1.4.4 The person responsible for an applicable source shall provide or cause to be provided, performance testing facilities as follows:

1.4.4.1 Sampling ports adequate for test methods applicable to such facility.

1.4.4.2 Safe sampling platform or platforms.

1.4.4.3 Safe access to sampling platform or platforms.

1.4.4.4 Utilities for sampling and testing equipment.

1.4.5 Each performance test shall consist of three separate runs using the applicable test method. Each run shall be conducted for the time and under the conditions specified in the applicable standards. For the purpose of determining compliance, the arithmetic mean of results of the three runs shall apply.

1.5 Compliance with Standard and Maintenance Requirements

1.5.1 Compliance with standards in the regulation, other than opacity standards, shall be determined only by performance test established by 1.4 of this regulation.

1.5.2 Compliance with standards in this regulation shall be determined by Reference Methods 1 through 12 and 15 through 25 set forth in Appendix A, 40 CFR Part 60, revised July 1, 1982, which are hereby adopted by reference. Where the person responsible for the applicable source can provide evidence acceptable to the Secretary that the presence of uncombined water is the only reason for failure to meet the opacity standard such failure shall not be a violation of the standard.

1.5.3 Compliance with opacity standards in this regulation shall be determined by conducting observations at consecutive 15-second intervals for a period of not less than one hour except that the observations may be discontinued whenever a violation of the applicable standard is recorded. The results of continuous monitoring by transmissometer which indicate that the opacity at the time visual observations were made was not in excess of the standard are probative but not conclusive evidence of the actual opacity of an emission, provided that the source shall meet the burden of proving that the instrument used meets, at the time of the alleged violation, Performance Specification 1, has been properly maintained and calibrated and that the resulting data have not been tampered with in any way.

The additional procedures, qualifications and testing to be used for visually determining the opacity of emissions shall be those specified in Section 2 and 3 (except for Section 2.5 and the second sentence of Section 2.4) of Reference Method 9 set forth in Appendix A, 40 CFR Part 60, revised July 1, 1982, which are hereby adopted by reference.

1.5.4 The opacity standards set forth in this regulation shall apply at all times including periods of startup and shutdown unless the emissions during startup and shutdown are governed by an operation permit.

1.5.5 At all times, including periods of startup, shutdown, and malfunction, owners and operators shall, to the extent practicable, maintain and operate any applicable source including associated air pollution control equipment in a manner consistent with good air pollution control practice for minimizing emissions. Determination of whether acceptable operating and maintenance procedures are being used will be based on information available to the Secretary which may include, but is not limited to, monitoring results, opacity observations, review of operating and maintenance procedures, and inspection of the source.

1.6 Circumvention. No owner or operator subject to the provisions of 1.0 of this regulation shall build, erect, install, or use any article, machine, equipment or process, the use of which conceals an emission, which would otherwise constitute a violation of an applicable standard. Such concealment includes, but is not limited to, the use of gaseous dilutants to achieve compliance with an opacity standard or with a standard, which is based on the concentration of a pollutant in the gases discharged to the atmosphere.

1.7 General Control Device Requirements. The provisions of Subpart A - General Provisions, Subsection 60.18 of Part 60, Title 40 of the Code of Federal Regulations, July 1, 1986 are hereby adopted by reference with the following changes:

1.7.1 The words "Act" and "Subpart A" are replaced by the words 7 DE Admin. Code 1101, DEFINITIONS AND ADMINISTRATIVE PRINCIPLES of the State of Delaware Regulations Governing the Control of Air Pollution."

1.7.2 Any subsections, from Title 40 of the Code of Federal Regulations, which are referenced in the text of the preceding adoption, are also adopted as part of this regulation.

04/18/1983

2.1 Applicability. Except as provided in 9.0 and 11.0 of this regulation, the provisions of 2.0 of this regulation are applicable to any fuel burning equipment of more than 250 million BTU per hour heat input, which is the applicable source. Any change to existing fuel burning equipment to accommodate the use of combustible fuels other than fossil fuels as defined herein shall not bring that equipment under the applicability of 2.0 of this regulation.

2.2 Standard for Particulate Matter. On and after the date on which the initial performance test is completed no person subject to the provisions of 2.0 of this regulation shall discharge or cause the discharge into the atmosphere of particulate matter, which is:

2.2.1 In excess of 0.10 lb. per million BTU heat input (0.18 grams per million calories heat input).

2.2.2 Greater than 20% opacity, except that a maximum of 40% opacity shall be permissible for not more than two minutes in any hour.

2.3 Standard for Sulfur Dioxide

2.3.1 On and after the date on which the initial performance test is completed with respect to a new stationary source in either Kent or Sussex Counties, the construction, reconstruction, or modification of which was commenced on or after August 17, 1971, no person subject to the provisions of 2.0 of this regulation shall discharge or cause the discharge into the atmosphere of sulfur dioxide in excess of 1.20 pounds per million BTU heat input (2.1 g. per million cal).

2.3.2 Compliance shall be based on the measured quantity of sulfur dioxide emitted divided by the total heat input for all fossil fuels burned, including gaseous fuels.

2.4 Standard for Nitrogen Oxides

2.4.1 On and after this date on which the initial performance test is completed no person subject to the provisions of 2.0 of this regulation shall discharge or cause the discharge into the atmosphere of nitrogen oxides in excess of:

2.4.1.1 0.20 lb per million BTU heat input (0.36 g. per million cal.), expressed as NO2, when gaseous fossil fuel is burned.

2.4.1.2 0.30 lb per million BTU heat input (0.54 g. per million cal.), expressed NO2 when liquid fossil fuel is burned.

2.4.1.3 0.70 lb. per million BTU heat input (1.26 g. per million cal.), expressed NO2, when solid fossil fuel is burned.

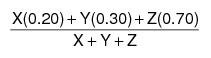

2.4.2 When different fossil fuels are burned simultaneously in any combination the applicable standard shall be determined by proration using the following formula:

where:

X is the percent of total heat input derived from gaseous fossil fuel and

Y is the percent of total heat input derived from liquid fuel and

Z is the percent of total heat input derived from solid fuel.

2.5 Emission and Fuel Monitoring

2.5.1 A continuous monitoring system for measuring the opacity of emissions, except where gaseous fuel is the only fuel burned, shall be installed, calibrated, maintained, and operated by the person responsible for the applicable sources. The continuous monitoring system shall be spanned at 80% or 90% or 100% opacity.

2.5.2 A continuous monitoring system for measuring sulfur dioxide emissions, shall be installed, calibrated, maintained and operated by the person responsible for the applicable source except where gaseous fuel is the only fuel burned or where low sulfur fuels are used to achieve compliance with the standard under 2.3 of this regulation and fuel analyses under 2.5.2.2 of this regulation are conducted. The following procedures shall be used for monitoring sulfur dioxide emissions:

2.5.2.1 For applicable sources which are continuous monitoring systems, Reference Method 6 shall be used for conducting monitoring system performance evaluations under 1.3.3 of this regulation. The pollutant gas used to prepare calibration gas mixtures under 2.1 of this regulation, Performance Specification 2 and for calibration checks under 1.3.4 of this regulation shall be sulfur dioxide SO2. The span value for the continuous monitoring system shall be determined as follows:

2.5.2.1.1 For applicable sources firing liquid fossil fuel the span value shall be 1000 ppm sulfur dioxide.

2.5.2.1.2 For applicable sources firing solid fossil fuel the span value shall be 1500 ppm sulfur dioxide.

2.5.2.1.3 For applicable sources firing fossil fuels in any combination, the span value shall be determined by computation in accordance with the following formula and rounding to the nearest 500 ppm sulfur dioxide:

1000Y + 1500Z (2-2)

where:

Y = the fraction of total heat input derived from liquid fossil fuel, and

Z = the fraction of total heat input derived from solid fossil fuel.

2.5.2.1.4 For applicable sources which fire both fossil fuels and non-fossil fuels, the span value shall be subject to the Secretary's approval.

2.5.2.2 For applicable sources using flue gas desulfurization systems to achieve compliance with sulfur dioxide standards under 2.3 of this regulation, the continuous monitoring system for measuring sulfur dioxide emissions shall be located downstream of the desulfurization system and in accordance with requirements in Performance Specification 2 and, other requirements of the Secretary which as a minimum shall be those specified in Section 60.45(b)(3) of 40 CFR 60, dated July 1, 1982.

2.5.3 A continuous monitoring system for the measurement of nitrogen oxides emissions shall be installed, calibrated, maintained, and operated by the responsible person except for any applicable source demonstrated during performance tests under 1.4 of this regulation to emit nitrogen oxides pollutants at a level 30% or more below applicable standards under 2.4 of this regulation. The following procedures shall be used for determining the span and for calibrating nitrogen oxides continuous monitoring systems:

2.5.3.1 The span value shall be determined as follows:

2.5.3.1.1 For applicable sources firing gaseous fossil fuel the span value shall be 500 ppm nitrogen oxides.

2.5.3.1.2 For applicable sources firing liquid fossil fuel the span value shall be 500 ppm nitrogen oxides.

2.5.3.1.3 For applicable sources firing solid fossil fuel the span value shall be 1000 ppm nitrogen oxides.

2.5.3.1.4 For applicable sources firing fossil fuels in any combination, the span value shall be determined by computation in accordance with the following formula and rounding to the nearest 500 ppm nitrogen oxides:

500(X + Y) + 1000Z (2-3)

where:

X = the fraction of total heat input derived from gaseous fossil fuel;

Y = the fraction of total heat input derived from liquid fossil fuel; and

Z = the fraction of the total heat input derived from solid fossil fuel.

2.5.3.1.5 For applicable sources which fire both fossil fuels and non-fossil fuels, the span value shall be subject to the Secretary's approval.

2.5.3.2 The pollutant gas used to prepare calibration gas mixtures under 2.1 of this regulation, Performance Specification 2 and for calibration checks under 1.3.4 of this regulation shall be nitric oxide (NO). Reference Method 7 shall be used for conducting monitoring system performance evaluations under 1.3.3 of this regulation.

2.5.4 A continuous monitoring system for measuring either oxygen or carbon dioxide in the flue gases shall be installed, calibrated, maintained, and operated by the person responsible for the applicable source.

2.5.5 Any person required to install continuous monitoring systems under 2.5.2 and 2.5.3 of this regulation shall for each pollutant monitored use the applicable conversion procedure for the purpose of converting continuous monitoring data into the units of the applicable standards. The applicable conversion procedures shall be those set forth in paragraphs (e) and (f) of Section 60.45 of 40 CFR 60, dated July 1, 1982.

2.5.6 For the purpose of reports required under 1.2 of this regulation, periods of excess emissions that shall be reported are defined as follows:

2.5.6.1 Sulfur dioxide - Excess emissions for applicable sources are defined as follows:

Any three-hour period during which the average emissions (arithmetic average of three continuous one–hour periods) of sulfur dioxide as measured by a continuous monitoring system exceed the applicable standard under 2.3 of this regulation.

2.5.6.2 Nitrogen Oxides - Excess emission for applicable sources using a continuous monitoring system for measuring nitrogen oxides are defined as any three-hour period during which the average emissions (arithmetic average of three continuous one–hour periods) exceed the applicable standards under 2.4 of this regulation.

2.6 Test Methods and Procedures

2.6.1 All performance tests shall be conducted while the applicable source is operating at or above the maximum steam production rate at which such facility will be operated and while fuels or combination of fuels representative of normal operation are being burned and under such other relevant conditions as the Secretary shall specify based on representative performance of the applicable source.

2.6.2 The reference methods in Appendix A of 40 CFR Part 60, except as provided in 1.4.2 of this regulation, shall be used to determine compliance with the standards prescribed herein as follows:

2.6.2.1 Method 1 for selection of sampling site and sample traverses.

2.6.2.2 Method 3 for gas analysis to be used when applying Reference Methods 5, 6 and 7.

2.6.2.3 Method 5 for concentration of particulate matter and the associated moister content.

2.6.2.4 Method 6 for concentration of SO2 and

2.6.2.5 Method 7 for concentration of NOx.

2.6.3 For method 5, the sampling time for each run shall be at least 60 minutes and the minimum sample volume shall be 0.85 dscm (30.0 dscf), except that smaller sampling times or volumes, when necessitated by process variables or other factors may be approved by the Secretary. The probe and filter holder heating systems in the sampling train shall be set to provide a gas temperature no greater than 160oC (320oF).

2.6.4 For Methods 6 and 7, the sampling site shall be the same as that for determining volumetric flow rate. The sampling point in the duct shall be at the centroid of the cross-section or at a point no closer to the walls than one m (3.28 ft.).

2.6.5 For Method 6, the minimum sampling times shall be 20 minutes and the minimum sample volume shall be 0.02 dscm (0.71 dscf). The sample shall be extracted at a rate proportional to the gas velocity at the sampling point. The arithmetic average of two samples shall constitute one run. Samples shall be taken at approximately 30-minute intervals.

2.6.6 For Method 7, each run shall consist of at least four grab samples taken at approximately 15-minute intervals. The arithmetic mean of the samples shall constitute the run value.

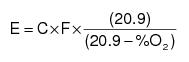

2.6.7 For each run the emissions expressed in g/million cal (lb./million BTU) shall be determined by the following procedure:

where:

E = pollutant emission, g/million cal (lb/million BTU);

C = pollutant concentration g/dscm (lb/dscf), determined by Methods 5, 6 and 7;

F = Factor to be determined by Methods approved by the Secretary.

%O2 = oxygen content by volume (expressed as %), dry basis. Percent Oxygen shall be determined by using the integrated or grab sampling and analysis procedures of Method 3 as applicable. The sample shall be obtained as follows:

2.6.7.1 For determination of sulfur dioxide and nitrogen oxides emissions, the oxygen sample shall be obtained simultaneously at the same point in the duct as used to obtain the samples for Methods 6 and 7 determinations, respectively. For Method 7, the oxygen sample shall be obtained using the grab sampling and analysis procedures of Method 3.

2.6.7.2 For determination of particulate emissions, the oxygen sample shall be obtained simultaneously by traversing the duct at the same sampling location used for each run of Method 5 under 2.6.3 of this regulation. Method 1 shall be used for selection of the number of traverse points except that no more than 12 sample points are required.

2.6.8 When combinations of fossil fuels are fired, the heat input, expressed in cal/hr (BTU/hr), shall be determined during each testing period by multiplying the gross calorific value of each fuel fired by the rate of each fuel burned. Gross calorific value shall be determined in accordance with A.S.T.M. methods D2015-66(72) (solid fuels.) D240-64(73) (liquid fuels), or D1826-64(70) (gaseous fuels) as applicable. The rate of fuels burned during each testing period shall be determined by suitable methods and shall be confirmed by a material balance over the steam generation system.

04/18/1983

3.1 Applicability. The provisions of 3.0 of this regulation are applicable to each nitric acid production unit, which is the applicable source.

3.2 Standard for Nitrogen Oxides. On and after the date on which the performance test is completed no person subject to the provisions of 3.0 of this regulation shall discharge or cause the discharge into the atmosphere of nitrogen oxides which are:

3.2.1 In excess of 3.0 lbs. per ton of acid produced (1.5 kg. per metric ton) expressed as HNO3.

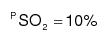

3.2.2 10% opacity or greater.

3.3 Emission Monitoring

3.3.1 A continuous monitoring system for the measurement of nitrogen oxides shall be installed, calibrated, maintained, and operated by the person responsible for the applicable source. The pollutant gas used to prepare calibration gas mixtures under 2.1 of this regulation, Performance Specification 2 and for calibration checks under 1.3.5 of this regulation shall be nitrogen dioxide NO2. The span shall be set at 500 ppm of nitrogen dioxide. Reference Method 7 shall be used for conducting monitoring system performance evaluations under 1.3.3 of this regulation.

3.3.2 The responsible person shall establish a conversion factor, approved by the Department for the purpose of converting monitoring data into units of the applicable standard (kg/metric ton, lb/short ton). The conversion factor shall be established by measuring emissions with the applicable reference method tests. Using only that portion of the continuous monitoring emission data that represents emission measurements concurrent with the reference method test periods, the conversion factor shall be determined by dividing the reference method test data averages by the monitoring data averages to obtain a ratio expressed in units of the monitoring data, i.e., kg/metric ton per ppm (lb/short ton per ppm). The conversion factor shall be reestablished during any performance test under 1.4 of this regulation or any continuous monitoring system performance evaluation under 1.3.3 of this regulation.

3.3.3 The responsible person shall record the daily production rate hours of operation.

3.3.4 For the purpose of reports required under 1.2.3 of this regulation, periods of excess emissions that shall be reported are defined as any three-hour period during which the average nitrogen oxides emissions (arithmetic average of three continuous one-hour periods) as measured by a continuous monitoring system exceed the standard under 3.2.1 of this regulation.

3.4 Test Methods and Procedures. All performance tests shall be conducted while the applicable source is operating at or above the maximum acid production rate at which such facility will be operated and under such other relevant conditions as the Secretary shall specify based on representative performance of the applicable source.

12/07/1988

The provisions of Subpart K-Standards of Performance for Storage Vessels for Petroleum Liquids for Which Construction, Reconstruction, or Modification Commenced After June 11, 1973, and Prior to May 19, 1978, of Part 60, Title 40 of the Code of Federal Regulations, July 1, 1986 and amended in the Federal Register on April 8, 1987, are hereby adopted by reference.

4.1 The words "Act" and "Subpart A" are replaced by the words 7 DE Admin. Code 1101, DEFINITIONS AND ADMINISTRATIVE PRINCIPLES of the State of Delaware Regulations Governing the Control of Air Pollution".

4.2 Any subsections, from Title 40 of the Code of Federal Regulations, which are referenced in the text of the preceding adoption are also adopted as part of this regulation.

04/18/1983

5.1 Applicability. The provisions of 5.0 of this regulation apply to each asphalt concrete plant, which is the applicable source.

5.2 Standard for Particulate Matter. On and after the date on which the initial performance test is completed no person subject to the provisions of 5.0 of this regulation shall discharge or cause the discharge into the atmosphere from any applicable source any such gases which:

5.2.1 Contain particulate matter in excess of 0.04 grain per dry standard cubic foot.

5.2.2 Exhibit 20% opacity, or greater.

5.3 Test Methods and Procedures. In addition to the test methods specified in Appendix A of 40 CFR Part 60, the following procedures are applicable:

5.3.1 Method 5 for the concentration of particulate matter and the associated moisture content.

5.3.2 Method 1 for sample and velocity traverses.

5.3.3 Method 2 for velocity and volumetric flow rate.

5.3.4 Method 3 for gas analysis.

5.3.5 For Method 5, the sampling time for each run shall be at least 60 minutes and the sampling rate shall be at least 0.9 dscm/hr. (0.53 dscf/min.), except that shorter sampling times, when necessitated by process variables or other factors, may be approved by the Secretary.

04/18/1983

6.1 Applicability. The provisions of 6.0 of this regulation are applicable to each incinerator of more than 3,000 pounds per hour charging rate, which is the applicable source.

6.2 Standard Particulate Matter. On and after the date on which the performance test required to be conducted is completed, no person responsible for the applicable source shall cause to be discharged into the atmosphere any gases which contain particulate matter in excess of 0.18 g./dscm (0.08 grain/dscf) corrected to 12% CO2.

6.3 Emission Monitoring. The person responsible for any incinerator subject to the provisions of 6.0 of this regulation shall record the hourly charging rates and hours of operation.

04/18/1983

7.1 Applicability. The applicable source to which the provisions of 7.0 of this regulation apply is each incinerator which burns the sludge produced by municipal sewage treatment facilities.

7.2 Standard for Particulate Matter. On and after the date on which the performance test required to be conducted by 1.4 of this regulation is completed, no person responsible for any sewage sludge incinerator subject to the provisions of 7.0 of this regulation shall discharge or cause the discharge into the atmosphere of:

7.2.1 Particulate matter at a rate in excess of 0.65 g/kg dry sludge input (1.30 lb/ton dry sludge input).

7.2.2 Any gases which exhibit 20% opacity or greater.

7.3 Emission Monitoring. The person responsible for any sludge incinerator subject to the provisions of 7.0 of this regulation shall:

7.3.1 Install, calibrate, maintain and operate a flow measuring device which can be used to determine either the mass of volume of sludge charged to the incinerator. The flow measuring device shall have an accuracy of +/-5.0% over its operating range.

7.3.2 Provide access to the sludge charged so that a well–mixed representative grab sample of the sludge can be obtained.

7.4 Test Methods and Procedures

7.4.1 The reference methods, except as provided for in 1.4.2 of this regulation, to be used to determine compliance with the standards prescribed in 7.2 of this regulation, are as follows:

7.4.1.1 Method 5 for concentration of particulate matter and associated moisture content,

7.4.1.2 Method 1 for sample and velocity traverses,

7.4.1.3 Method 2 for volumetric flow rate, and

7.4.1.4 Method 3 for gas analysis.

7.4.2 For Method 5, the sampling time for each run shall be at least 60 minutes and the sampling rate shall be at least 0.015 dscm/min (0.53 dscf/min.), except that shorter sampling times, when necessitated by process variable or other factors, may be approved by the Secretary.

7.4.3 Dry sludge charging rate shall be determined by methods set forth in Section 60.154 of 40 CFR 60, dated July 1, 1982, which are hereby adopted by reference.

04/18/1983

8.1 Applicability. The provisions of 8.0 of this regulation are applicable to each sulfuric acid plant, which is the applicable source.

8.2 Standard for Sulfur Dioxide. On and after date on which the performance test required to be conducted by 1.4 of this regulation is completed, no person subject to the provisions of 8.0 of this regulation shall cause to be discharged into the atmosphere from any applicable source any gases which contain sulfur dioxide in excess of two kg per metric ton of acid produced (four lbs per ton), the production being expressed as 100% H2SO4.

8.3 Standard for Acid Mist. On and after the date on which the performance test required to be conducted by 1.4 of this regulation is completed, no person subject to the provisions of 8.0 of this regulation shall cause to be discharged into the atmosphere from any applicable source any gases which

8.3.1 Contain acid mist, expressed as H2SO4, in excess of 0.075 kg per metric ton of acid produced (0.15 lb per ton), the production being expressed as 100% H2SO4.

8.3.2 Exhibit 10% opacity, or greater.

8.4 Emission Monitoring

8.4.1 A continuous monitoring system for the measurement of sulfur dioxide shall be installed, calibrated, maintained, and operated by the person responsible for the applicable source. The pollutant gas used to prepare calibration gas mixtures under 2.1 of this regulation, Performance Specification 2 and for calibration checks under 1.3.5 of this regulation shall be sulfur dioxide (SO2). Reference Method 8 shall be used for conducting monitoring system performance evaluation under 1.3.3 of this regulation except that only the sulfur dioxide portion of the Method 8 results shall be used. The span shall be set at 1,000 ppm of sulfur dioxide.

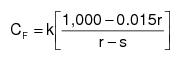

8.4.2 The responsible person shall establish a conversion factor for the purpose of converting monitoring data into units of the applicable standard (kg/metric ton, lb/short ton). The conversion factor shall be determined, as a minimum, three times daily by measuring the concentration of sulfur dioxide entering the converter using suitable methods (e.g., the Reich test, National Air Pollution Control Administration Publication No. 999-AP-13) and calculating the appropriate conversion factor for each eight -hour period as follows:

(8-1)

where:

CF = conversion factor (kg/metric ton per ppm, lb/short ton per ppm).

k = constant derived from material balance.

For determining CF in metric units, k = 0.0653.

For determining CF in English units, k = 0.1306.

r = percentage of sulfur dioxide by volume entering the gas converter.

Appropriate corrections must be made for air injection plants subject to the Secretary's

approval.

s = percentage of sulfur dioxide by volume in the emissions to the atmosphere determined by the continuous monitoring system required under 8.4.1 of this regulation.

8.4.3 The responsible person shall record all conversion factors and values under 8.4.2 of this regulation from which they are computed (i.e., CF, r, and s).

8.4.4 For the purpose of reports under 1.2.3 of this regulation periods of excess emissions shall be all three-hour periods (or the arithmetic average of three consecutive one-hour periods) during which the integrated average sulfur dioxide emissions exceed the applicable standards under 8.2 of this regulation.

8.5 Test Methods and Procedures

8.5.1 All performance tests shall be conducted while the applicable source is operating at or above the maximum acid production rate at which such source will be operated and under such other relevant conditions as the Secretary shall specify based on representative performance of the applicable source.

8.5.2 The reference methods in Appendix A of 40 CFR Part 60, except as provided for in 1.4.2 of this regulation, shall be used to determine compliance with the standards prescribed in 8.2 and 8.3 of this regulation as follows:

8.5.2.1 Method 8 for the concentrations of SO2 and acid mist;

8.5.2.2 Method 1 for sample and velocity traverses;

8.5.2.3 Method 2 for velocity and volumetric flow rate; and

8.5.2.4 Method 3 for gas analysis.

8.5.3 The moisture content can be considered to be zero. For Method 8 the sampling time for each run shall be at least 60 minutes and the minimum sample volume shall be 1.15 dscm (40.6 dscf) except that smaller sampling times or sample volumes, when necessitated by process variables or other factors, may be approved by the Secretary.

8.5.4 Acid production rate, expressed in metric tons per hour of 100% H2SO4, shall be determined during each testing period by suitable methods and shall be confirmed by a material balance over the production system.

8.5.5 Acid mist and sulfur dioxide emissions, expressed in g/metric ton of 100% H2SO4, shall be determined by dividing the emission rate in g/hr by the acid production rate. The emission rate shall be determined by the equation, g/hr = Qs x C, where Qs = volumetric flow rate of the effluent in dscm/hr as determined in accordance with 8.5.2.3 of this regulation, and C = acid mist and SO2 concentrations in g/dscm as determined in accordance with 8.5.2.1 of this regulation.

04/18/1983

9.0 Standards of Performance for Electric Utility Steam Generating Units for Which Construction is Commenced after September 18, 1978

9.1 Applicability and Designation of Affected Facility

9.1.1 Any facility covered under 9.0 of this regulation is not subject to the provisions of 2.0 of this regulation. The affected facility to which 9.0 of this regulation applies is each electric utility steam generating unit:

9.1.1.1 That is capable of combusting more than 73 megawatts (250 million BTU/hr) heat input of fossil fuel (either alone or in combination with any other fuel); and

9.1.1.2 For which construction or modification is commenced after September 18, 1978.

9.1.2 The 9.0 of this regulation applies to electric utility combined cycle gas turbines that are capable of combusting more than 73 megawatts (250 million BTU/hour) heat input of fossil fuel in the steam generator. Only emissions resulting from combustion of fuels in the steam generating unit are subject to 9.0 of this regulation. (The gas turbine emissions are subject to Subpart GG, 40 CFR Part 60).

9.1.3 Any change to an existing fossil-fuel-fired steam generating unit to accommodate the use of combustible materials, other than fossil fuels, shall not bring the unit under the applicability of 9.0 of this regulation.

9.1.4 Any change to an existing steam generating unit originally designed to fire gaseous or liquid fossil fuels, to accommodate the use of any other fuel (fossil or nonfossil) shall not bring that unit under the applicability of 9.0 of this regulation.

9.2 [Reserved]

9.3 [Reserved]

9.4 [Reserved]

9.5 [Reserved]

9.6 [Reserved]

9.7 [Reserved]

9.8 [Reserved]

9.9 [Reserved]

9.10 [Reserved]

9.11 Definitions

As used in 9.0 of this regulation, all terms not defined herein shall have the meaning given them in the Clean Air Act and in 7 DE Admin. Code 1101.

“Anthracite” means coal that is classified as anthracite according to the American Society of Testing and Materials' (ASTM) Standard Specification for Classification of Coals by Rank D388-66.

“Available purchase power” means the lesser of the following:

(a) The sum of available system capacity in all neighboring companies.

(b) The sum of the rated capacities of the power interconnection devices between the principal company and all neighboring companies, minus the sum of the electric power load on these interconnections.

(c) The rated capacity of the power transmission lines between the power interconnection devices and the electric generating units (the unit in the principal company that has the malfunctioning flue gas desulfurization system and the unit or units in the neighboring company supplying replacement electrical power) less the electric power load on these transmission lines.

“Available system capacity” means the capacity determined by subtracting the system load and the system emergency reserves from the net system capacity.

“Boiler operating day” means a 24-hour period during which fossil fuel is combusted in a steam generating unit for the entire 24 hours.

“Coal refuse” means waste products of coal mining, physical coal cleaning, and coal preparation operations (e.g. culm, gob, etc.) containing coal, matrix material, clay, and other organic and inorganic material.

“Combined cycle gas turbine” means a stationary turbine combustion system where heat from the turbine exhaust gases is recovered by a steam generating unit.

“Electric utility steam generating unit” means any steam electric generating unit that is constructed for the purpose of supplying more than one-third of its potential electric output capacity and more than 25 MW electrical output to any utility power distribution system for sale. Any steam supplied to a steam distribution system for the purpose of providing steam to a steam-electric generator that would produce electrical energy for sale is also considered in determining the electrical energy output capacity of the affected facility.

“Electric utility company” means the largest interconnected organization business, or governmental entity that generates electric power for sale (e.g., a holding company with operating subsidiary companies).

“Emergency condition” means that period of time when:

(a) The electric generation output of an affected facility with a malfunctioning flue gas desulfurization system cannot be reduced or electrical output must be increased because:

(1) All available system capacity in the principal company interconnected with the affected facility is being operated, and

(2) All available purchase power interconnected with the affected facility is being obtained, or

(b) The electric generation demand is being shifted as quickly as possible from an affected facility with a malfunctioning flue gas desulfurization system to one or more electrical generating units held in reserve by the principal company or by a neighboring company, or

(c) An affected facility with a malfunctioning flue gas desulfurization system becomes the only available unit to maintain a part or all of the principal company's system emergency reserves and the unit is operated in spinning reserve at the lowest practical electric generation load consistent with not causing significant physical damage to the unit. If the unit is operated at a higher load to meet load demand, an emergency condition would not exist unless the conditions under (a) of this definition apply.

“Electric utility combined cycle gas turbine” means any combined cycle gas turbine used for electric generation that is constructed for the purpose of supplying more than one -third of its potential electric output capacity and more than 25 MW electrical output to any utility power distribution system for sale. Any steam distribution system that is constructed for the purpose of providing steam to a steam electric generator that would produce electrical power for sale is also considered in determining the electrical energy output capacity of the affected facility.

“Fossil fuel” means natural gas, petroleum, coal, and any form of solid, liquid, or gaseous fuel derived from such material for the purpose of creating useful heat.

“Interconnected” means that two or more electric generating units are electrically tied together by a network of power transmission lines, and other power transmission equipment.

“Lignite” means coal that is classified as lignite A or B according to the American Society of Testing and Materials' (ASTM) Standard Specification for Classification of Coals by Rank D388-66.

“Neighboring company” means any one of those electric utility companies with one or more electric power interconnections to the principal company and which have geographically adjoining service areas.

“Net system capacity” means the sum of the net electric generating capability (not necessarily equal to rated capacity) of all electric generating equipment owned by an electric utility company (including steam generating units, internal combustion engines, gas turbines, nuclear units, hydroelectric units, and all other electric generating equipment) plus firm contractual purchases that are interconnected to the affected facility that has the malfunctioning flue gas desulfurization system. The electric generating capability of equipment under multiple ownership is prorated based on ownership unless the proportional entitlement to electric output is otherwise established by contractual arrangement.

“Potential combustion concentration” means the theoretical emissions (nanograms per joule, ng/J or lb/million BTU heat input) that would result from combustion of a fuel in an uncleaned state without emission control systems) and:

(a) For particulate matter, is:

(1) 3,000 ng/J (7.0 lb/million BTU) heat input for solid fuel; and

(2) 75 ng/J (0.17 lb./million BTU) heat input for liquid fuels.

(b) For sulfur dioxide, is determined under 9.18.2 of this regulation.

(c) For nitrogen oxides, is:

(1) 290 ng/J (0.67 lb/million BTU) heat input for gaseous fuels;

(2) 310 ng/J (0.72 lb/million BTU) heat input for liquid fuels; and

(3) 990 ng/J (2.30 lb/million BTU) heat input for solid fuels.

“Potential electrical output capacity” is defined as 33% of the maximum design heat input capacity of the steam generating unit (e.g., a steam generating unit with a 100-MW (340 million BTU/hr) fossil-fuel heat input capacity would have a 33-MW potential electrical output capacity). For electric utility combined cycle gas turbines the potential electrical output capacity is determined on the basis of the fossil-fuel firing capacity of the steam generator exclusive of the heat input and electrical power contribution by the gas turbine.

“Principal company” means the electric utility company or companies which own the affected facility.

“Resource recovery unit” means a facility that combusts more than 75% non-fossil fuel on a quarterly (calendar) heat input basis.

“Solid-derived fuel” means any solid, liquid, or gaseous fuel derived from solid fuel for the purpose of creating useful heat and includes, but is not limited to, solvent refined coal, liquified coal, and gasified coal. "24-hour period" means the period of time between 12:01 a.m. and 12:00 midnight.

“Spare flue gas desulfurization system module” means a separate system of sulfur dioxide emission control equipment capable of treating an amount of flue gas equal to the total amount of flue gas generated by an affected facility when operated at maximum capacity divided by the total number of nonspare flue gas desulfurization modules in the system.

“Spinning reserve” means the sum of the unutilized net generating capability of all units of the electric utility company that are synchronized to the power distribution system and that are capable of immediately accepting additional load. The electric generating capability of equipment under multiple ownership is prorated based on ownership unless the proportional entitlement to electric output is otherwise established by contractual arrangement.

“Steam generating unit” means any furnace, boiler, or other device used for combusting fuel for the purpose of producing steam (including fossil-fuel-fired steam generators associated with combined cycle gas turbines; nuclear steam generators are not included).

“Subbituminous coal” means coal that is classified as subbituminous A, B, or C according to the American Society of Testing and Materials' (ASTM) Standard Specification for Classification of Coals by Rank D388-66.

“System load” means the entire electric demand of an electric utility company's service area interconnected with the affected facility that has the malfunctioning flue gas desulfurization system plus firm contractual sales to other electric utility companies. Sales to other electric utility companies (e.g., emergency power) not on a firm contractual basis may also be included in the system load when no available system capacity exists in the electric utility company to which the power is supplied for sale.

“System emergency reserves” means an amount of electric generating capacity equivalent to the rated capacity of the single largest electric generating unit in the electric utility company (including steam generating units, internal combustion engines, gas turbines, nuclear units, hydroelectric units, and all other electric generating equipment) which is interconnected with the affected facility that has the malfunctioning flue gas desulfurization system. The electric generating capability of equipment under multiple ownership is prorated based on ownership unless the proportional entitlement to electric output is otherwise established by contractual arrangement.

9.12 Standard for Particulate Matter

9.12.1 On and after the date on which the performance test required to be conducted under 1.4 of this regulation is completed, no owner or operator subject to the provisions of 9.0 of this regulation shall cause to be discharged into the atmosphere from any affected facility any gases which contain particulate matter in excess of:

9.12.1.1 13 ng/J (0.03 lb/million BTU) heat input derived from the combustion of solid, liquid, or gaseous fuel;

9.12.1.2 1% of the potential combustion concentration (99% reduction) when combusting solid fuel; and

9.12.1.3 30% of potential combustion concentration (70% reduction) when combusting liquid fuel.

9.12.2 On and after the date the particulate matter performance test required to be conducted under 1.4 of this regulation is completed, no owner or operator subject to the provisions of 9.0 of this regulation shall cause to be discharged into the atmosphere from any affected facility any gases which exhibit greater than 20% opacity except for one six-minute period per hour of not more than 27% opacity.

9.13 Standard for Sulfur Dioxide

9.13.1 On and after the date on which the initial performance test required to be conducted under 1.4 of this regulation is completed, no owner or operator subject to the provisions of 9.0 of this regulation shall cause to be discharged into the atmosphere from any affected facility which combusts solid fuel or solid -derived fuel, except as provided under 9.13.3, 9.13.4, 9.13.5 or 9.13.7 of this regulation, any gases which contain sulfur dioxide in excess of:

9.13.1.1 520 ng/J (1.2 lb/million BTU) heat input and 10% of the potential combustion concentration (90% reduction), or

9.13.1.2 30% of the potential combustion concentration (70% reduction), when emissions are less than 260 ng/J (0.60 lb/million BTU) heat input.

9.13.2 On and after the date on which the initial performance test required to be conducted under 1.4 of this regulation is completed, no owner or operator subject to the provisions of 9.0 of this regulation shall cause to be discharged into the atmosphere from any affected facility which combusts liquid or gaseous fuels (except for liquid or gaseous fuels derived from solid fuels and as provided under 9.13.7 of this regulation), any gases which contain sulfur dioxide in excess of:

9.13.2.1 340 ng/J (0.8 lb/million BTU) heat input and 10% of the potential combustion concentration (90 percent reduction), or

9.13.2.2 100% of the potential combustion concentration (0% reduction) when emissions are less than 86 ng/J (0.20 lb/million BTU) heat input.

9.13.3 On and after the date on which the initial performance test required to be conducted under 1.4 of this regulation is complete, no owner or operator subject to the provisions of 9.0 of this regulation shall cause to be discharged into the atmosphere from any affected facility which combusts solid solvent refined coal (SRC-I) any gases which contain sulfur dioxide in excess of 520 ng/J (1.2 lb/million BTU) heat input and 15% of the potential combustion concentration (85% reduction) except as provided under 9.13.5 of this regulation; compliance with the emission limitation is determined on a 30–day rolling average basis and compliance with the percent reduction requirement is determined on a 24-hour basis.

9.13.4 Sulfur dioxide emissions are limited to 520 ng/J (1.2 lb/million BTU) heat input from any affected facility which:

9.13.4.1 Combusts 100% anthracite,

9.13.4.2 Is classified as a resource recovery facility.

9.13.5 The emission reduction requirements under 9.0 of this regulation do not apply to any affected facility that is operated under an SO2 commercial demonstration permit issued by the Administrator of the U.S. Environmental Protection Agency in accordance with the provisions of 9.15 of this regulation.

9.13.6 Compliance with the emission limitation and percent reduction requirements under 9.0 of this regulation are both determined on a 30 day rolling average basis except as provided under 9.13.3 of this regulation.

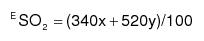

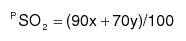

9.13.7 When different fuels are combusted simultaneously, the applicable standard is determined by proration using the following formula:

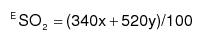

9.13.7.1 If emissions of sulfur dioxide to the atmosphere are greater than 260 ng/J (0.60 lb/million BTU) heat input:

(9-1)

(9-1)

(9-2)

9.13.7.2 If emissions of sulfur dioxide to the atmosphere are equal to or less than 260 ng/J (0.60 lb/million BTU) heat input:

(9-3)

(9-4)

where:

ESO2 is the prorated sulfur dioxide emission limit (ng/J heat input);

PSO2 is the percentage of potential sulfur dioxide emission allowed (percent reduction required = 100 - PSO2);

x is the percentage of total heat input derived from the combustion of liquid or gaseous fuels (excluding solid -derived fuels);

y is the percentage of total heat input derived from the combustion of solid fuel (including solid-derived fuels).

9.14 Standard for Nitrogen Oxides

9.14.1 On and after the date on which the initial performance test required to be conducted under 1.4 of this regulation is completed, no owner or operator subject to the provisions of 9.0 of this regulation shall cause to be discharged into the atmosphere from any affected facility, except as provided under 9.14.2 of this regulation, any gases which contain nitrogen oxides in excess of the following emission limits, based on a 30-day rolling average.

9.14.1.1 NOx Emission Limits

Emission Limit | ||

Fuel Type | ng/J Heat Input | (lb/million BTU Heat Input) |

Gaseous Fuels: | ||

Coal–derived fuels | 210 | (0.50) |

All other fuels | 86 | (0.20) |

Liquid Fuels: | ||

Coal–derived fuels | 210 | (0.50) |

Shale oil | 210 | (0.50) |

All other fuels | 130 | (0.30) |

Solid Fuels: | ||

Coal–derived | 210 | (0.50) |

Lignite not subject to the 340 ng/J heat input emission limit | 260 | (0.60) |

Subbituminous coal | 210 | (0.50) |

Bituminous coal | 260 | (0.60) |

Anthracite coal | 260 | (0.60) |

All other fuels | 260 | (0.60) |

Any fuel containing more than 25% by weight coal refuse is exempt from NOx standards and NOx monitoring requirements. | ||

9.14.1.2 NOx reduction requirements

Fuel Type | Percent Reduction of Potential Combustion Concentration |

Gaseous Fuels | 25% |

Liquid Fuels | 30% |

Solid Fuels | 65% |

9.14.2 The emission limitations under 9.14.1 of this regulation do not apply to any affected facility which is combusting coal-derived liquid fuel and is operating under a commercial demonstration permit issued by the Secretary in accordance with the provisions of 9.15 of this regulation.

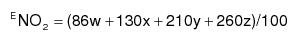

9.14.3 When two or more fuels are combusted simultaneously, the applicable standard is determined by proration using the following formula:

(9-5)

where:

ENO2 is the applicable standard for nitrogen oxides when multiple fuels are combusted simultaneously (ng/J heat input);

w is the percentage of total heat input derived from the combustion of fuels subject to the 86 ng/J heat input standard;

x is the percentage of total heat input derived from the combustion of fuels subject to the 130 ng/J heat input standard;

y is the percentage of total heat input derived from the combustion of fuels subject to the 210 ng/J heat input standard; and

z is the percentage of total heat input derived from the combustion of fuels subject to the 260 ng/J heat input standard.

9.15 Commercial Demonstration Permit

9.15.1 An owner or operator of an affected facility proposing to demonstrate an emerging technology may apply to the Administrator of the U.S. Environmental Protection Agency for a commercial demonstration permit. Commercial demonstration permits may be issued only by the Administrator of the U.S. Environmental Protection Agency.

9.15.2 An owner or operator of an affected facility that combusts solid solvent refined coal (SRC-I) and who is issued a commercial demonstration permit by the Administrator of the U.S. Environmental Protection Agency is not subject to the SO2 emission reduction requirements under 9.13.3 of this regulation but must, as a minimum, reduce SO2 emissions to 20% of the potential combustion concentration (80% reduction) for each 24-hour period of steam generator operation and to less than 520 ng/J (1.2 lb/million BTU) heat input on a 30-day rolling average basis.

9.15.3 An owner or operator of a fluidized bed combustion electric utility steam generator (atmospheric or pressurized) who is issued a commercial demonstration permit by the Administrator of the U.S. Environmental Protection Agency is not subject to the SO2 emissions reduction requirements under 9.13 of this regulation but must, as a minimum, reduce SO2 emissions to 15% of the potential combustion concentration (85% reduction) on a 30-day rolling average basis and to less than 520 ng/J (1.2 lb/million BTU) heat input on a 30-day rolling average basis.

9.15.4 The owner or operator of an affected facility that combusts coal-derived liquid fuel and who is issued a commercial demonstration permit by the Administrator of the U.S. Environmental Protection Agency is not subject to the applicable NOx emission limitation and percent reduction under 9.14 of this regulation but must, as a minimum, reduce emissions to less than 300 ng/J (0.70 lb/million BTU) heat input on a 30-day rolling average basis.

9.16 Compliance Provisions

9.16.1 Compliance with the particulate matter emission limitation under 9.12.1.1 of this regulation constitutes compliance with the percent reduction requirements for particulate matter under 9.12.1.2 and 9.12.1.3 of this regulation.

9.16.2 Compliance with the nitrogen oxides emission limitation under 9.14.1 of this regulation constitutes compliance with the percent reduction requirements under 9.14 of this regulation.

9.16.3 The particulate matter emission standards under 9.12 of this regulation and the nitrogen oxides emission standards under 9.14 of this regulation apply at all times except during periods of startup, shutdown, or malfunction. The sulfur dioxide emission standards under 9.13 of this regulation apply at all times except during periods of startup, shutdown, or when both emergency conditions exist and the procedures under 9.16.4 of this regulation are implemented.

9.16.4 During emergency conditions in the principal company, an affected facility with a malfunctioning flue gas desulfurization system may be operated pursuant to a variance, issued under the provisions of 7 Del.C., Ch 60, §6011 or §6012, which requires that sulfur dioxide emissions be minimized by at least the following actions:

9.16.4.1 Operating all operable flue gas desulfurization system modules, and bringing back into operation any malfunctioned module as soon as repairs are completed.

9.16.4.2 Bypassing flue gases around only those flue gas desulfurization system modules that have been taken out of operation because they were incapable of any sulfur dioxide emission reduction or which would have suffered significant physical damage if they had remained in operation, and

9.16.4.3 Designing, constructing, and operating a spare flue gas desulfurization system module for an affected facility larger than 365 MW (1,250 million BTU/hr) heat input (approximately 125 MW electrical output capacity). The Secretary may at his discretion require the owner or operator within 60 days of notification to demonstrate spare module capability. To demonstrate this capability, the owner or operator must demonstrate compliance with the appropriate requirements under 9.13.1, 9.13.2, 9.13.4 and 9.13.7 of this regulation for any period of operation lasting from 24 hours to 30 days when:

9.16.4.3.1 Any one flue gas desulfurization module is not operated.

9.16.4.3.2 The affected facility is operating at the maximum heat input rate,

9.16.4.3.3 The fuel fired during the 24-hour to 30-day period is representative of the type and average sulfur content of fuel used over a typical 30-day period, and

9.16.4.3.4 The owner or operator has given the Secretary at least 30 days notice of the date and period of time over which the demonstration will be performed.

9.16.5 After the initial performance test required under 1.4 of this regulation, compliance with the sulfur dioxide emission limitations and percentage reduction requirements under 9.13 of this regulation and the nitrogen oxides emission limitations under 9.14 of this regulation is based on the average emission rate for 30 successive boiler operating days. A separate performance test is completed at the end of each boiler operating day after the initial performance test, and a new 30 day average emission rate for both sulfur dioxide and nitrogen oxides and a new percent reduction for sulfur dioxide are calculated to show compliance with the standards in 9.0 of this regulation.

9.16.6 For the initial performance test required under 1.4 of this regulation, compliance with the sulfur dioxide emission limitations and percent reduction requirements under 9.13.1 of this regulation and the nitrogen oxides emission limitation under 9.14.1 of this regulation is based on the average emission rates for sulfur dioxide, nitrogen oxides, and percent reduction for sulfur dioxide for the first 30 successive boiler operating days. The initial performance test is the only test in which at least 30 days prior notice is required unless otherwise specified by the Secretary. The initial performance test is to be scheduled so that the first boiler operating day of the 30 successive boiler operating days is completed within 60 days after achieving the maximum production rate at which the affected facility will be operated, but not later than 180 days after initial startup of the facility.

9.16.7 Compliance is determined by calculating the arithmetic average of all hourly emission rates for SO2 and NOx for the 30 successive boiler operating days, except for data obtained during startup, shutdown, malfunction (NOx only), or emergency conditions (SO2 only). Compliance with the percentage reduction requirement for SO2 is determined based on the average inlet and average outlet SO2 emission rates for the 30 successive boiler operating days.