DEPARTMENT OF NATURAL RESOURCES AND ENVIRONMENTAL CONTROL

Division of Air Quality

FINAL

Secretary’s Order No.: 2021-A-0009

RE: Approving Final Regulations to Amend 7 DE Admin. Code 1124, Control of

Volatile Organic Compound Emissions, Section 36.0, Vapor Emission Control

at Gasoline Dispensing Facilities

Date of Issuance: March 11, 2021

Effective Date of the Amendment: April 11, 2021

1124 Control of Volatile Organic Compound Emissions

Under the authority vested in the Secretary of the Department of Natural Resources and Environmental Control ("Department" or "DNREC"), pursuant to 7 Del.C. §§6006 and 6010, and all other relevant statutory authority, the following findings of fact based on the record, reasons and conclusions are entered as an Order of the Secretary in the above-referenced promulgation.

Background, Procedural History and Findings of Fact

This Order relates to proposed regulation amendments ("Amendments") to 7 DE Admin. Code 1124, Control of Volatile Organic Compound Emissions, Section 36.0, Vapor Emission Control at Gasoline Dispensing Facilities ("Regulation"). Specifically, the Department proposes to amend the Regulation to update the California Air Resources Board ("CARB") Executive Orders (as modified between July 17, 2019 and June 3, 2020) referenced in the Amendments regarding Stage I enhanced vapor recovery systems used at Delaware gasoline dispensing facilities. The proposed Amendments include updates of the latest Executive Order numbers, the effective dates, and will provide the regulated community with additional Stage I enhanced vapor recovery ("EVR") system component flexibility.

On July 11, 2020 the Department adopted amendments to the Regulation (hereafter referred to as the "2020 Amendment") to establish adjustments to the Regulation and specific compliance schedules. The 2020 Amendment requires gasoline dispensing facilities in Delaware to install one of the Stage I EVR systems certified in CARB Executive Orders to meet 98% volatile organic compound's emission control efficiency. The CARB Executive Orders demonstrate compliance with the CARB certification and list the individual components that can be used within a certified Stage I EVR system. Six (6) CARB Executive Orders for Stage I EVR systems were incorporated into the 2020 Amendment.

During the time of the Department's regulatory development of the 2020 Amendments, CARB modified their Executive Orders for Stage I EVR systems from July 17, 2019 through June 3, 2020. The Department is now incorporating these modifications in the Amendments to reflect the most recent updates to CARB Executive Order numbers VR-1010-T, VR-102-U, VR-104-K, VR-105-I, VR401-F, VR-402-E, and VR-202-Z. The latest update to the CARB Executive Orders include: (1) modifications to the Husky Model 5885 Pressure/Vacuum vent valve; (2) the extension of certifications of the modified 5885 Pressure/Vacuum vent valve to May 31, 2021; (3) the addition of OPW 723 Pressure/Vacuum vent valve for E85 applications; and (4) the addition of the Franklin Fueling aluminum drop tube and Defender Overfill Protection Valve to the equipment list as alternate parts in Executive Order VR 102.

More specifically, the Amendments include the title number changes of CARB Executive Orders referenced in the following Regulation subsections: (1) 36.4.1.1.1 through 36.4.1.1.4; (2) 36.4.1.2.1 through 36.4.1.2.2, (3) 36.10.2, and (4) 36.11.3.1 through 36.11.3.6. In addition, the Amendments include adding a phrase in subsection 36.1.3 to specify July 1, 2019 as the effective date of 40 CFR 80.22(j).

The Department published its initial proposed Amendments in the November 1, 2020 Delaware Register of Regulations. Thereafter the public hearing notice was issued, the Department revised the proposed Amendments to include a non-substantive change. Referenced in subsections 36.5.1, 36.5.3, and 36.11.5, the non-substantive change revises the CARB Executive Order "VR-202-W (August 30, 2018)" to "VR-202-Z (November 5, 2019)".

The virtual public hearing regarding this matter was held on December 8, 2020. There were two (2) members of the public in attendance at the virtual public hearing. Pursuant to 29 Del.C. §10118(a), the hearing record remained open for receipt of written comment for 30 days following the public hearing. The hearing record formally closed for comment in this matter at close of business on January 7, 2021, with one (1) comment received by the Department during the phase of this formal promulgation. It should be noted that the proposed revised Amendments were fully vetted at the time of the virtual public hearing.

Subsequent to the close of record, the Department's Division of Air Quality staff prepared a Technical Response Memorandum to address the comment received by the public.

Thereafter, Hearing Officer Theresa Newman prepared her report dated January 27, 2021 ("Report"), which expressly incorporated the Department's proposed Amendments into the hearing record generated in this matter. The Report documents the proper completion of the required regulatory amendment process, establishes the record, and recommends the adoption of the proposed revised Amendments as attached to the Report as Appendix "A."

The Department has the statutory basis and legal authority to act with regard to the formal promulgation of these proposed revised Amendments, pursuant to 7 Del.C. §6010(a) and (c). It should be noted that all notification and noticing requirements concerning this matter were met by the Department. Proper notice of the hearing was provided as required by law.

Reasons and Conclusions

Based on the record developed by the Department's staff in the Division of Air Quality, and established by the Hearing Officer's Report, I find that the proposed revised regulatory Amendments are well-supported and will enable the Department to update the CARB Executive Orders (as modified between July 17, 2019 and June 3, 2020) referenced in the Amendments regarding Stage I EVR systems used at Delaware gasoline dispensing facilities and will provide the regulated community with additional Stage I EVR system component flexibility. I further find that the Department's Air Quality experts fully developed the record to support adoption of these Amendments. Therefore, the recommendations of the Hearing Officer are hereby adopted, and I direct that the proposed Amendments be promulgated as final.

The following reasons and conclusions are hereby entered:

1. The Department has the statutory basis and legal authority to act with regard to this proposed regulatory promulgation, pursuant to 7 Del. C. §6010(a) and (c);

2. The Department has jurisdiction under its statutory authority, pursuant to 7 Del.C. Ch. 60, to issue an Order adopting these proposed revised Amendments as final;

3. The Department provided adequate public notice of the initial proposed Amendments and all proceedings in a manner required by the law and regulations, and provided the public with an adequate opportunity to comment on the same, including at the time of the virtual public hearing held on December 8, 2020 and during the 30 days subsequent to the hearing (through January 7, 2021), before making any final decision;

4. Promulgation of the proposed revised Amendments to 7 DE Admin. Code 1124: Section 36.0, Vapor Emission Control at Gasoline Dispensing Facilities, will enable the Department to update CARB Executive Order numbers and effective dates (as modified between July 17, 2019 and June 3, 2020), referenced in the Amendments regarding Stage I EVR systems used at Delaware gasoline dispensing facilities, and provide the regulated community with additional Stage I EVR system component flexibility;

5. The Department has reviewed the proposed revised Amendments in the light of the Regulatory Flexibility Act, consistent with 29 Del.C. §104, and believes the same to be lawful, feasible and desirable, and the recommendations as proposed should be applicable to all Delaware citizens equally;

6. The Department's Hearing Officer's Report, including its established record and the recommended proposed Amendments as set forth in Appendix "A," are hereby adopted to provide additional reasons and findings for this Order;

7. The Department's proposed regulatory Amendments, as initially published in the November 1, 2020 Delaware Register of Regulations, and then subsequently revised, as set forth in Appendix "A" hereto, are adequately supported, are not arbitrary or capricious, and are consistent with the applicable laws and regulations. Consequently, they are approved as final regulatory Amendments, which shall go into effect ten days after their publication in the next available issue of the Delaware Register of Regulations; and

8. The Department has an adequate Record for its decision, and no further public hearing is appropriate or necessary; and

9. The Department shall submit this Order approving the proposed revised Amendments as final regulatory to the Delaware Register of Regulations for publication in its next available issue, and provide such other notice as the law and regulation require and the Department determines is appropriate.

Shawn M. Garvin

Secretary

1124 Control of Volatile Organic Compound Emissions

01/11/2017

1.1 This regulation, "Control of Volatile Organic Compound Emissions", replaces and supersedes Regulation No. 24, "Control of Volatile Organic Compound Emissions" dated July 3, 1990.

1.2 This regulation is applicable to the sources of Volatile Organic Compounds (VOCs) as set-forth herein, except:

1.2.1 Sources, other than solvent metal-cleaning sources, whose emissions of Volatile Organic Compounds (VOCs) are not more than fifteen (15) pounds per day, unless other limits are specified herein, provided the emission rates are determined and certified in a manner acceptable to the Department.

1.2.2 Sanitary landfills conforming to the State of Delaware Statewide Solid Waste Management Plan.

1.3 No owner or operator shall substitute either methyl chloroform or methylene chloride for any other Volatile Organic Compound (VOC) for any solvent metal cleaning purpose on or after the effective date of this regulation.

1.4 Reserved.

1.5 Any owner or operator currently permitted to operate a VOC emission source under 7 DE Admin. Code 1102 or the previous Regulation No. 24 shall submit to the Department, within 90 days of the effective date of this regulation, an application to amend the current permit and to comply with the provisions of this regulation. Any owner or operator of a non-permitted source subject to the provisions of this regulation, on and after the effective date of the regulation, shall immediately submit to the Department an application for a permit to construct, modify, reconstruct or operate the source.

1.6 Any owner or operator who owns or operates a process or operation regulated by a subsequent section of this regulation may submit to the Department proposals for alternative compliance schedules. The Department may, with the concurrence of the Administrator of the U. S. Environmental Protection Agency (U.S. EPA), approve the alternative compliance schedules if:

1.6.1 The proposal contains projected increments of progress which are substantially equivalent to the compliance schedules in the appropriate subsequent sections of this regulation, and,

1.6.2 Final compliance with emission standards is achieved not later than that stipulated in appropriate subsequent sections of this regulation, or not later than May 31, 1995, if agreed in writing by the Department.

1.7 In the event that the applicant's schedule of interim measures is not acceptable, the Department shall give written notice to the applicant, advising that the schedule contained in the appropriate sections of this regulation will be ordered unless an equitable compromise is agreed-upon, or a public hearing is requested. The expense of such hearing shall be borne by the applicant. The Department may order a schedule to be implemented after considering relevant testimony at the hearing, or, if no hearing is requested, issue an order on its own initiative.

1.8 Any alternative compliance schedule approved by the Department shall be incorporated in the State Implementation Plan (SIP).

04/11/2010

For the purpose of this regulation, the following definitions apply:

“Actual emissions” means the quantity VOCs emitted from a source during a particular time period.

"Adhesion primer" means a coating that is applied to thermoplastic olefin (TPO) parts to promote adhesion of subsequent coatings. An adhesion primer is clearly identified as an adhesion primer or adhesion promoter on its accompanying material safety data sheet.

“Aerosol coating product” means a pressurized coating product containing pigments or resins that dispenses product ingredients by means of a propellant and in packaged in a disposable can for hand-held application, or for use in specialized equipment for ground traffic marking applications.

“Air-dried coating” means a coating that is cured at a temperature below 90o C (194o F).

“As applied” means including any dilution solvents added before application of the coating.

“Baked coating” means a coating that is cured at a temperature at or above 90o C (194o F).

“Basecoat” means a pigmented topcoat that is the first coat applied as part of a multistage topcoat system.

“Bulk gasoline plant” means a gasoline storage and distribution facility with an average daily throughput of 76,000 liters (L) (20,000 gallons [gal]) of gasoline or less on a monthly average.

“Bulk gasoline terminal” means a gasoline storage facility that receives gasoline from refineries, delivers gasoline to bulk gasoline plants or to commercial or retail accounts, and has a daily throughput of more than 76,000 L (20,000 gal) of gasoline on a monthly average.

“Capture efficiency” means the weight per unit time of VOC entering a capture system and delivered to a control device divided by the weight per unit time of total VOC generated by a source of VOC, expressed as a percentage.

“Capture system” means all equipment (including, but not limited to, hoods, ducts, fans, booths, ovens, dryers, etc.) that contains, collects, and transports an air pollutant to a control device.

“Carbon absorber” means an add-on control device that uses activated carbon to absorb VOCs from a gas stream.

“Carbon adsorption system" means a carbon adsorber with an inlet and outlet for exhaust gases and a system to regenerate the saturated adsorbent.

“Clearcoat” means a topcoat that contains no pigments or only transparent pigments and that is the final coat applied as part of a multistage topcoat system.

“Coating” means a material applied onto or impregnated into a substrate for protective, decorative, or functional purposes. Such materials include, but are not limited to, paints, varnishes, sealants, adhesives, inks, maskants, and temporary protective coatings.

“Coating unit” means a series of one or more coating applicators and any associated drying area or oven wherein a coating is applied, dried, or cured. A coating unit ends at the point where the coating is dried or cured, or prior to any subsequent application of a different coating. It is not necessary to have an oven or a flash-off area in order to be included in this definition.

“Continuous vapor control system” means a vapor control system that treats vapors displaced from tanks during filling on a demand basis without intermediate accumulation.

“Control device” means equipment (such as an incinerator or carbon adsorber) used to reduce, by destruction or removal, the amount of air pollutant or pollutants in an air stream prior to discharge to the ambient air.

“Control system” means a combination of one or more capture system or systems and control device or devices working in concert to reduce discharges of pollutants to the ambient air.

“Day” means a period of 24 consecutive hours beginning at midnight local time, or beginning at a time consistent with a facility's operating schedule.

“Destruction or removal efficiency” means the amount of VOC destroyed or removed by a control device expressed as a percent of the total amount of VOC entering the device.

"Dip coating" means the application method of a coating material to a substrate by dipping the part into a tank of coating material.

“Double block-and-bleed system” means two block valves connected in series with a bleed valve or line that can vent the line between the two block valves.

"Electric-insulating and thermal-conducting coating" means a coating that displays an electrical insulation of at least 1000 volts DC per mil on a flat test plate and an average thermal conductivity of at least 0.27 BTU per hour-foot-degree Fahrenheit.

"Electrostatic spray" means a method of applying a spray coating in which opposite electric charges are applied to the substrate and the coating. The coating is attracted to the substrate by the electrostatic potential between them.

“Exempt compounds” means any of the compounds listed in 2.0 of 7 DE Admin. Code 1101 - Definitions, "Volatile Organic Compounds," which have been determined to have negligible photochemical reactivity.

For determining compliance with emission limits, VOCs will be measured according to the procedures in Methods 25 and 25A of Appendix A of 40 CFR, Part 60, and the procedures and equations in §60.755. Where such a method also measures compounds with negligible photochemical reactivity, an owner or operator may exclude these negligibly-reactive compounds when determining compliance with an emission standard. However, the Department may require such owner or operator, as a precondition to excluding these compounds for purposes of determining compliance, to provide monitoring methods and monitoring results demonstrating, to the satisfaction of the Department, the amount of negligibly-reactive compounds in the sources emissions.

In addition to the procedures for requesting a satisfactory compliance determination, where the Department proposes to allow the use of a test method for excluding negligibly-reactive compounds that is different or not specified in the approved SIP, such change shall be submitted to the U.S. EPA for approval as part of a SIP revision.

“External floating roof” means a cover over an open-top storage tank consisting of a double deck or pontoon single deck that rests upon and is supported by the volatile organic liquid being contained and is equipped with a closure seal or seals to close the space between the roof edge and tank shell.

"Extreme high-gloss coating" means a coating which, when tested by ASTM International Method D-523, adopted in 1980, shows a reflectance of 75 or more on a 600 meter.

"Extreme performance coating" means a coating used on a metal surface where the coated surface is, in its intended use, subject to the following; (a) chronic exposure to corrosive, caustic or acidic agents, chemicals, chemical fumes, chemical mixtures or solutions: or (b) repeated exposure to temperatures in excess of 250 0F; or (c) repeated heavy abrasion, including mechanical wear and repeated scrubbing with industrial grade solvents, cleansers of scouring agents.

“Facility” means all of the pollutant-emitting activities, excluding pollutant-emitting activities from mobile sources that are located on one or more contiguous or adjacent properties, and are under the control of the same person (or person under common control).

“First attempt at repair” means to take rapid action for the purpose of stopping or reducing leakage of organic material to the atmosphere using best practices.

“Flash-off area” means the space between the coating application area and the oven.

"Flow coating" means the application of a coating material to a substrate by pouring the coating over the suspended part.

“Gasoline tank truck” means a delivery tank truck used at bulk gasoline plants, bulk gasoline terminals, or gasoline dispensing facilities that is loading or unloading gasoline or that has loaded or unloaded gasoline on the immediately previous load.

“Gloss flattener” means a low-gloss coating that is formulated to eliminate glare on the interior surfaces of a vehicle for safety purposes, as specified under the U.S. Department of Transportation Motor Vehicle Safety Standards.

"Hand application" means a method of applying coatings by non-mechanical hand-held equipment, including, but not limited to, paint brushes, hand rollers, caulking guns, trowels, spatulas, syringe daubers, rags and sponges.

“Heavy-duty truck” means any motor vehicle rated at greater than 3,864 kg (8,500 lb) gross weight designed primarily to transport property.

"High-volume, low-pressure (HVLP) spray equipment" means spray equipment that is used to apply coatings using a spray gun that operates less than or equal to 10 psig of atomized air pressure at the air cap.

“Incinerator” means a combustion apparatus in which solid, semisolid, liquid, or gaseous combustible wastes are ignited and burned and from which the solid and gaseous residues contain little or no combustible material.

“Intermittent vapor control system” means a vapor control system that employs an intermediate vapor holder to accumulate vapors displaced from tanks during filling. The control device treats the accumulated vapors only during automatically controlled cycles.

“Internal Floating Roof” means a cover or roof in a fixed-roof tank that rests upon or is floated upon, the liquid being contained, and is equipped with a closure seal or seals to close the space between the roof edge and the tank shell.

“Knife coating” means the application of a coating material to a substrate by means of drawing the substrate beneath a knife that spreads the coating evenly over the full width of the substrate.

“Leak” means a VOC emission indicated by an instrument calibrated according to Method 21 of 40 CFR, Part 60, Appendix A, using zero air (less than 10 parts per million [ppm] of hydrocarbon in air) and a mixture of methane or n-hexane and air at a concentration of about, but less than, 10,000 ppm methane or n-hexane.

“Lease custody transfer” means the transfer of produced crude oil or condensate, after processing or treating in the producing operations, from storage tanks or automatic transfer facilities to pipelines or any other forms of transportation.

“Liquid-mounted seal” means a primary seal mounted in continuous contact with the liquid between the tank wall and the floating roof around the circumference of the tank.

“Loading rack” means an aggregation or combination of gasoline loading equipment arranged so that all loading outlets in the combination can be connected to a tank truck or trailer parked in a specified loading space.

“Lower explosive limit” (LEL) means the concentration of a compound in air below which a flame will not propagate if the mixture is ignited.

“Maximum theoretical emissions” means the quantity of VOC that theoretically could be emitted by a source without control devices based on the design capacity or maximum production capacity of the source and 8,760 hours of operation per year. The design capacity or maximum production capacity includes use of coatings and inks with the highest VOC content used in practice by the source for the two preceding years.

“Maximum true vapor pressure” means the equilibrium partial pressure exerted by a stored liquid at the temperature equal to:

1. for liquids stored above or below the ambient temperature, the highest calendar-month average of the liquid storage temperature, or

2. for liquids stored at the ambient temperature, the local maximum monthly average temperature as reported by the National Weather Service. This pressure shall be determined by one of the following:

i. In accordance with methods described in American Petroleum Institute Bulletin 2517, "Evaporation Loss From External Floating Roof Tanks."

ii. By using standard reference texts.

iii. By ASTM D2879-83.

iv. By any other method approved by the Department as part of the State Implementation Plan (SIP) Revision.

"Metallic coating" means a coating which contains more than 5 grams of metal particles per liter of coating, as applied. Metal particles are pieces of a pure elemental metal or a combination of elemental metals.

"Mold-seal coating" means the initial coating applied to a new mold or a repaired mold to provide a smooth surface which, when coated with a mold release coating prevents products from sticking to the mold.

“Multicomponent coating” means a coating which is packaged in two or more parts, which parts are combined before application, and where a coreactant from one part of the coating chemically reacts, at ambient conditions, with a coreactant from another part of the coating.

"One-component coating" means a coating that is ready for application as it comes out of its container to form an acceptable dry film. A thinner, necessary to reduce the viscosity, is not considered a component.

“Open-ended valve or line” means any valve, except safety relief valves, having one side of the valve seat in contact with process fluid and one side open to the atmosphere, either directly or through open piping.

“Organic compound” means any carbon-containing chemical compound excluding carbon monoxide, carbon dioxide, carbonic acid, metallic carbides or carbonates, and ammonium carbonate.

“Oven” means a chamber which is used to bake, cure, polymerize, or dry a coating.

“Overall emission reduction efficiency” means the weight per unit time of VOC removed or destroyed by a control device divided by the weight per unit time of VOC generated by a source, expressed as a percentage. The overall emission reduction efficiency can also be calculated as the product of the capture efficiency and the control device destruction or removal efficiency.

“Owner or Operator” means any person who owns, leases, controls, operates or supervises a facility, a source, or air pollution control or monitoring equipment.

“Person” means any individual, partnership, copartnership, firm, company, corporation, association, joint stock company, trust, estate, political subdivision, or any other legal entity, or their legal representative, agent, or assigns.

“Petroleum” means the crude oil removed from the earth and the oils derived from tar sands, shale and coal.

“Petroleum Liquid” means petroleum condensate, and any finished or intermediate products manufactured in a petroleum refinery.

“Plastisol” means a coating made of a mixture of finely divided resin and a plasticizer. Plastisol is applied as a thick gel that solidifies when heated.

“Press-Ready Ink” means the ink, as applied to the substrate, after all solvents and diluents have been added.

“Pressure release” means the emission of materials resulting from system pressure being greater than set pressure of the pressure relief device.

"Pretreatment coating" means a coating which contains no more than 12% solids by weight, and at least 0.5% acid by weight, is used to provide surface etching, and is applied directly to metal surfaces to provide corrosion resistance, adhesion, and ease of stripping.

“Primer” means any coating applied prior to the application of a topcoat or color coat for the purposes of surface preparation, corrosion resistance, adhesion, and color uniformity.

“Process unit shutdown” means a work practice or operational procedure that stops production from a process unit or part of a process unit. An unscheduled work practice or operational procedure that stops production from a process unit or part of a process unit for less than 24 hours is not a process unit shutdown. The use of spare equipment and technically feasible bypassing of equipment without stopping production are not process unit shutdowns.

“Reid vapor pressure” means the absolute vapor pressure of volatile crude oil and volatile nonviscous petroleum liquids, except liquified petroleum gases, as determined by ASTM D323-82.

"Repair coating" means a coating used to re-coat portions of a previously coated product which has sustained mechanical damage to the coating following normal coating operations.

“Repaired” means that equipment is adjusted, or otherwise altered, in order to eliminate a leak as indicated by one of the following: an instrument reading of 10,000 ppm or greater, indication of liquids dripping, or indication by a sensor that a seal or barrier fluid system has failed.

“Roll coating” means the application of a coating material to a moving substrate by means of hard rubber, elastomeric, or metal rolls.

“Rotogravure coating” means the application of a coating material to a substrate by means of a roll coating technique in which the pattern to be applied is recessed relative to the non-image area, and the coating material is picked up in these recessed areas and is transferred to the substrate.

"Safety-indicating coatings" means a coating which changes physical characteristics, such as color, to indicate unsafe conditions.

“Shutdown” means the cessation of operation of a facility or of its emission control or emission monitoring equipment.

"Solar-absorbent coating" means a coating which has as its prime purpose the absorption of solar radiation.

"Solid-film lubricant" means a very thin coating consisting of a binder system containing as its chief pigment material one or more of molybdenum disulfide, graphite, polytetraflouroethylene (PTFE) or other solids that act as a dry lubricant between faying surfaces.

“Source” means any building, structure, equipment (excluding mobile equipment temporarily in place), or installation that directly or indirectly releases or discharges, or has the potential to release or discharge, VOCs into the atmosphere.

“Stage I Vapor Recovery System” means the control of gasoline vapor from any delivery vessel into any stationary storage vessel, where the vapor displaced by the liquid gasoline is returned to the delivery vessel and transported to the refinery.

“Stage II Vapor Recovery System” means a system that controls the emissions of gasoline vapor at the vehicle fill-pipe, where the vapor is captured and returned to a vapor-tight storage tank, or is destroyed; which achieves an overall control efficiency of at least 95%.

“Standard conditions” means a temperature of 20oC (68oF) and pressure of 760 mm Hg (29.92 in. Hg).

“Startup” means the setting in operation of a source or of its emission control or emission monitoring equipment.

"Stencil coating" means a coating which is rolled or brushed onto a template or stamp in order to add identifying letters, symbols or numbers.

“Storage Vessel” means each tank, reservoir or container used for the storage of Volatile Organic Liquids, but does not include:

1. Frames, housing, auxiliary supports or other components that are not directly involved in the containment of liquids or vapors; or

2. Subsurface caverns or porous rock reservoirs.

“Submerged fill” means the method of filling a delivery vessel or storage vessel where product enters within 150 millimeters (mm) (5.9 inches [in.]) of the bottom of the delivery or storage vessel. Bottom filling of delivery and storage vessels is included in this definition.

“Substrate” means the surface onto which a coating is applied or into which a coating is impregnated.

“Throughput” means the amount of gasoline dispensed at a gasoline dispensing facility during a calendar month after November 15, 1990.

"Touch-up coating" means a coating used to cover minor coating imperfections appearing after the main coating operation.

“Transfer efficiency” means the ratio of the amount of coating solids adhering to the object being coated to the total amount of coating solids used in the application process, expressed as a percentage.

"Two-component paint" means a coating that is manufactured in two components that are mixed shortly before use. When mixed, the two liquids rapidly crosslink to form a solid composition.

"Vacuum-metalizing coating" means the undercoat applied to the substrate on which the metal is deposited or the overcoat applied directly to the metal film. Vacuum metalizing/physical vapor deposition (PVD) is the process whereby metal is vaporized and deposited on a substrate in a vacuum chamber.

“Vapor collection system” means all piping, seals, hoses, connections, pressure-vacuum vents, and other equipment between the gasoline tank truck and the vapor processing unit or the storage tanks and vapor holder.

“Vapor control system” means a system that limits or prevents release to the atmosphere of organic compounds in the vapors displaced from a tank during the transfer of gasoline.

“Vapor-mounted seal” means a primary seal mounted so there is an annular vapor space underneath the seal. The annular vapor space is bounded by the bottom of the primary seal, the tank wall, the liquid surface and the floating roof.

“Vapor recovery system” means a vapor-gathering system capable of collecting VOC vapors and gases emitted during the operation of any transfer, storage, or process equipment.

“Vapor-tight” means equipment that allows no loss of vapors. Compliance with vapor-tight requirements can be determined by checking to ensure that the concentration at a potential leak source is not equal to or greater than 100% of the LEL when measured with a combustible gas detector, calibrated with propane, at a distance of 2.54 centimeters (cm) (1 inch) from the source.

“Vapor-tight gasoline tank truck” means a gasoline tank truck that has demonstrated within the 12 preceding months that its product delivery tank will sustain a pressure change of not more than 75 mm (3.0 in.) of water within five minutes (min) after it is pressurized to 450 mm (18 in.) of water; or when evacuated to 150 mm (5.9 in.) of water, the same tank will sustain a pressure change of not more than 75 mm (3.0 in.) of water within 5 min. This capability is to be demonstrated using the test procedures specified in Method 27 of Appendix A of 40 CFR, Part 60 (July 1, 1992).

“Volatile Organic Liquid” (VOL) means any organic liquid which can emit any Volatile Organic Compound into the atmosphere (see definition of "Volatile Organic Compound" of this regulation).

“Volatile Organic Compound” (VOC) means any carbon-containing compound excluding carbon monoxide, carbon dioxide, carbonic acid, metallic carbides or carbonates and ammonium carbonate, which participates in atmospheric photochemical reactions. This includes any organic compounds other than those defined as "Exempt Compounds", which have been determined to have negligible photochemical reactivity (see definition of "Exempt Compounds" of this regulation). In addition to the procedures for requesting a satisfactory compliance demonstration, where the Department proposes to allow the use of a test method for excluding negligibly reactive compounds that is different from or not specified in the approved SIP, such change shall be submitted to the Environmental Protection Agency (U.S. EPA) for approval as part of a SIP Revision.

“Web coating line” means all of the coating applicator or applicators, drying area or areas, or oven or ovens, located between an unwind station and a rewind station, that are used to apply coating onto a continuous strip of substrate (the web). A web coating line need not have a drying oven.

01/11/1993

3.1 All existing, new, reconstructed and modified sources shall meet all applicable provisions of this regulation.

3.2 Nothing in this regulation shall be construed to exempt new, reconstructed or modified sources from meeting any other applicable Department or federal rules, including New Source Review requirements.

3.3 This regulation does not apply to any equipment at a facility used exclusively for chemical or physical analysis or determination of product quality and commercial acceptance provided the operation of the equipment is not an integral part of the production process and the total actual emissions from all such equipment at the facility do not exceed 204 kilograms (kg) (450 pounds [lb]) in any calendar month. Any facility claiming exemption from the provisions 3.3 of this regulation shall comply with the provisions of 3.5 of this regulation.

3.4

3.4.1 Any facility that becomes or is currently subject to the provisions of this regulation by exceeding an applicability threshold will remain subject to these provisions, even if its throughput or emissions later fall below the applicability threshold, except as provided in 3.7 of this regulation.

3.4.2 Any facility that is currently subject to a state or federal rule promulgated pursuant to the Clean Air Act Amendments of 1977 by exceeding an applicability threshold is and will remain subject to these provisions, even if its throughput or emissions have fallen or later fall below the applicability threshold.

3.5 Any facility that claims exemption from the provisions of this regulation by reason of meeting the conditions in 3.3 of this regulation shall maintain the following annual records in a readily accessible location for at least 5 years and shall make those records available to the Department upon verbal or written request:

3.5.1 Records to document the purpose of the equipment for which the exemption is claimed.

3.5.2 Records to document the amount of each volatile organic compound (VOC)-containing material used in the equipment each calendar month and the VOC content of each material such that emissions can be determined for each calendar month.

3.6 The owner or operator of a facility or source subject to any control requirement of this regulation may comply with an alternative control plan that has been approved by the Department and the U.S. EPA.

3.7 The owner or operator of a facility or source subject to this regulation may petition the Department for exemption from the requirements of this regulation upon a showing that such facility or source no longer has the potential to emit Volatile Organic Compounds (VOCs). Any exemption granted shall be embodied in a Consent Order which shall contain terms and conditions necessary to ensure that no Volatile Organic Compounds (VOCs) may be emitted from the facility or source. For federal enforcement purposes, such exemption shall not be effective until approved by the U.S. EPA.

4.1 To establish the records required under 4.0 of this regulation, the volatile organic compound (VOC) content of each coating, as applied, and the efficiency of each capture system and control device shall be determined by the applicable test methods and procedures specified in Appendix B and Appendix D of this regulation.

4.2 Requirements for coating sources exempt from emission limitations. Any owner or operator of a coating unit, line, or operation that is exempt from the emission limitations of 10.0 through 23.0 of this regulation because combined VOC emissions from all coating units, lines, and operations at the facility are below the applicability threshold specified in the individual sections of this regulation, before the application of capture systems and control devices, shall comply with the following for each section of this regulation from which the owner or operator claims an exemption:

4.2.1 Certification. By November 15, 1993, the owner or operator of a facility referenced in 4.2 of this regulation shall certify to the Department that the facility is exempt from emission limitations by providing all of the following:

4.2.1.1 The name and location of the facility.

4.2.1.2 The address and telephone number of the person responsible for the facility.

4.2.1.3 A declaration that the facility is exempt from the emission limitations of 10.0 through 23.0 of this regulation because combined VOC emissions from all coating units, lines, and operations at the facility that are covered by an individual section of this regulation are below the appropriate applicability threshold before the application of capture systems and control devices.

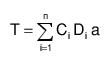

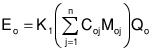

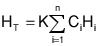

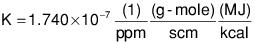

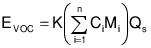

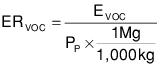

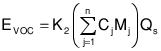

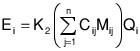

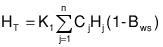

4.2.1.4 Calculations of the daily-weighted average that demonstrate that the combined VOC emissions from all coating units, lines, and operations at the facility that are covered by an individual section of this regulation for a day representative of current maximum production levels are less than 6.8 kilograms (kg) (15 pounds [lb]) before the application of capture systems and control devices. The following equation shall be used to calculate total VOC emissions for that day:

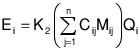

where:

T = Total VOC emissions from coating units, lines, and operations at the facility before the application of capture systems and control devices in units of kg/day (lb/day).

n = Number of different coatings applied on each coating unit, each coating line, or each operation at the facility.

i = Subscript denoting an individual coating.

Ai = Mass of VOC per volume of coating (i) (excluding water and exempt compounds), as applied, used at the facility in units of kilograms VOC per liter (kg VOC/L) (pounds VOC per gallon [lb VOC/gal]).

Bi = Volume of coating (i) (excluding water and exempt compounds), as applied, used at the facility in units of liters per day (L/day) (gallons per day [gal/day]). The instrument or method by which the owner or operator accurately measured or calculated the volume of each coating, as applied, used at the facility shall be described in the certification to the Department.

4.2.2 Recordkeeping. On and after November 15, 1993, the owner or operator of a facility referenced in 4.2 of this regulation shall collect and record all of the following information each day and maintain the information at the facility for a period of 5 years:

4.2.2.1 The name and identification number of each coating, as applied.

4.2.2.2 The mass of VOC per volume (excluding water and exempt compounds) and the volume of coating (i) (excluding water and exempt compounds), as applied, used each day.

4.2.2.3 The total VOC emissions at the facility, as calculated using the equation under 4.2.1.4 of this regulation.

4.2.3 Reporting. On and after November 15, 1993, the owner or operator of a facility referenced in 4.2 of this regulation shall notify the Department of any record showing that combined VOC emissions from all coating units, lines, and operations at the coating facility exceed 6.8 kg (15 lb) on any day, before the application of capture systems and control devices. A copy of such record shall be sent to the Department within 45 calendar days after the exceedance occurs. This reporting requirement is in addition to any other exceedance reporting requirements mandated by the State of Delaware.

4.3 Requirements for coating sources using complying coatings. Any owner or operator of a coating unit, line, or operation subject to the limitations of 10.0 through 12.0 or 13.3.1 or 14.0 through 23.0 of this regulation and complying by means of the use of complying coatings shall comply with the following:

4.3.1 Certification. By November 15, 1993, or upon startup of a new coating unit, line, or operation, or upon changing the method of compliance for an existing subject coating unit, line, or operation from daily-weighted averaging or control devices to the use of complying coatings, the owner or operator of a coating unit, line, or operation referenced in 4.3 of this regulation shall certify to the Department that the coating unit, line, or operation is or will be in compliance with the requirements of the applicable section of this regulation on and after November 15, 1993, or on and after the initial startup date. Such certification shall include:

4.3.1.1 The name and location of the facility.

4.3.1.2 The address and telephone number of the person responsible for the facility.

4.3.1.3 Identification of subject sources.

4.3.1.4 The name and identification number of each coating, as applied, on each coating unit, line, or operation.

4.3.1.5 The mass of VOC per volume (excluding water and exempt compounds) and the volume of each coating (excluding water and exempt compounds), as applied per day.

4.3.1.6 The time at which the facility's "day" begins if a time other than midnight local time is used to define a "day."

4.3.2 Recordkeeping. On and after November 15, 1993, or on and after the initial startup date, the owner or operator of a coating unit, line, or operation referenced in 4.3 of this regulation and complying by the use of complying coatings shall collect and record all of the following information each day for each coating unit, line, or operation and maintain the information at the facility for a period of five years:

4.3.2.1 The name and identification number of each coating, as applied, on each coating unit, line, or operation.

4.3.2.2 The mass of VOC per volume of each coating (excluding water and exempt compounds), as applied, used each day on each coating unit, line, or operation.

4.3.2.3 The volume of each coating applied each day on each coating unit line or operation.

4.3.3 Reporting. On and after November 15, 1993, the owner or operator of a subject coating unit, line, or operation referenced in 4.3 of this regulation shall notify the Department in either of the following instances:

4.3.3.1 Any record showing use of any non-complying coatings shall be reported by sending a copy of such record to the Department within 45 calendar days following that use.

4.3.3.2 At least 30 calendar days before changing the method of compliance from the use of complying coatings to daily-weighted averaging or control devices, the owner or operator shall comply with all requirements of 4.4.1 or 4.5.1 of this regulation, respectively, as well as 7 DE Admin. Code 1102. Upon changing the method of compliance from the use of complying coatings to daily-weighted averaging or control devices, the owner or operator shall comply with all requirements of the section of this regulation applicable to the coating unit, line, or operation referenced in 4.3 of this regulation.

4.4 Requirements for coating sources using daily-weighted averaging. Any owner or operator of a coating unit, line, or operation subject to the limitations of 10.0 through 12.0 or 13.3.1 or 14.0 through 23.0 of this regulation and complying by means of daily-weighted averaging on that unit, line, or operation shall comply with the following:

4.4.1 Certification. By November 15, 1993, or upon startup of a new coating unit, line, or operation, or upon changing the method of compliance for an existing subject coating unit, line, or operation from the use of complying coatings or control devices to daily-weighted averaging, the owner or operator of the subject coating unit, line, or operation shall certify to the Department that the coating unit, line, or operation is or will be in compliance with 4.4 of this regulation on and after November 15, 1993, or on and after the initial startup date. Such certification shall include:

4.4.1.1 the name and location of the facility.

4.4.1.2 the address and telephone number of the person responsible for the facility.

4.4.1.3 Identification of subject sources.

4.4.1.4 The name and identification number of each coating unit, line, or operation that will comply by means of daily-weighted averaging.

4.4.1.5 The instrument or method by which the owner or operator will accurately measure or calculate the volume of each coating (excluding water and exempt compounds), as applied, used each day on each coating unit, line, or operation.

4.4.1.6 The method by which the owner or operator will create and maintain records each day as required in 4.4.2 of this regulation.

4.4.1.7 Calculation of the daily-weighted average, using the procedure in 1.0 of Appendix C of this regulation, for a day representative of current or projected maximum production levels.

4.4.1.8 The time at which the facility's "day" begins if a time other than midnight local time is used to define a "day."

4.4.2 Recordkeeping. On and after November 15, 1993, or on and after the initial startup date, the owner or operator of a coating unit, line, or operation referenced in 4.4 of this regulation and complying by means of daily-weighted averaging shall collect and record all of the following information each day for each coating unit, line, or operation and maintain the information at the facility for a period of five years:

4.4.2.1 The name and identification number of each coating, as applied, on each coating unit, line, or operation.

4.4.2.2 The mass of VOC per volume (excluding water and exempt compounds) and the volume of each coating (excluding water and exempt compounds), as applied, used each day on each coating unit, line, or operation.

4.4.2.3 The daily-weighted average VOC content of all coatings, as applied, on each coating unit, line, or operation calculated according to the procedure in 1.0 of Appendix C of this regulation.

4.4.3 Reporting. On and after November 15, 1993, the owner or operator of a subject coating unit, line, or operation referenced in 4.4 of this regulation shall notify the Department in either of the following instances:

4.4.3.1 Any record showing noncompliance with the applicable daily-weighted average requirements shall be reported by sending a copy of the record to the Department within 45 calendar days following the occurrence.

4.4.3.2 At least 30 calendar days before changing the method of compliance from daily-weighted averaging to the use of complying coatings or control devices, the owner or operator shall comply with all requirements of 4.3.1 or 4.5.1 of this regulation, respectively, as well as 7 DE Admin. Code 1102. Upon changing the method of compliance from daily-weighted averaging to the use of complying coatings or control devices, the owner or operator shall comply with all requirements of the section of this regulation applicable to the coating unit, line, or operation referenced in 4.4 of this regulation.

4.5 Requirements for coating sources using control devices. Any owner or operator of a coating unit, line, or operation subject to the limitations of 10.0 through 23.0 of this regulation and complying by means of control devices shall comply with the following:

4.5.1 Testing of control equipment. By November 15, 1993, or upon startup of a new coating unit, line, or operation, or upon changing the method of compliance for an existing coating unit, line, or operation from the use of complying coatings or daily-weighted averaging to control devices, the owner or operator of the subject coating unit, line, or operation shall perform a compliance test. Testing shall be performed within 90 days of startup, and pursuant to the procedures in Appendix A through Appendix D of this regulation. The owner or operator of the subject coating unit, line, or operation shall submit to the Department the results of all tests and calculations necessary to demonstrate that the subject coating unit, line, or operation is or will be in compliance with the applicable section of this regulation on and after November 15, 1993, or on and after the initial startup date.

4.5.2 Recordkeeping. On and after November 15, 1993, or on and after the initial startup date, the owner or operator of a coating unit, line, or operation referenced in 4.5 of this regulation shall collect and record all of the following information each day for each coating unit, line, or operation and maintain the information at the facility for a period of five years:

4.5.2.1 The name and identification number of each coating used on each coating unit, line, or operation.

4.5.2.2 The mass of VOC per unit volume of coating solids, as applied, the volume solids content, as applied, and the volume, as applied, of each coating used each day on each coating unit, line, or operation.

4.5.2.3 The maximum VOC content (mass of VOC per unit volume of coating solids, as applied) or the daily-weighted average VOC content (mass of VOC per unit volume of coating solids, as applied) of the coatings used each day on each coating unit, line, or operation.

4.5.2.4 The required overall emission reduction efficiency for each day for each coating unit, line, or operation as determined in 10.5.1.3, 11.4, 12.5.1.3, 13.5.1.3, 14.5.1.3, 15.5.1.3, 16.5.1.3, 17.5.1.3, 18.5.1.3, 19.5.1.3, 20.5.1.3, 21.5.1.3, 22.5.1.3, 23.5.1.3 of this regulation.

4.5.2.5 The actual overall emission reduction efficiency achieved for each day for each coating unit, line, or operation as determined in 3.0 of Appendix D of this regulation.

4.5.2.6 Control device monitoring data.

4.5.2.7 A log of operating time for the capture system, control device, monitoring equipment, and the associated coating unit, line, or operation.

4.5.2.8 A maintenance log for the capture system, control device, and monitoring equipment detailing all routine and non-routine maintenance performed including dates and duration of any outages.

4.5.2.9 For thermal incinerators, all 3-hour periods of operation in which the average combustion temperature was more than 28°C (50°F) below the average combustion temperature during the most recent performance test that demonstrated that the facility was in compliance. The combustion chamber set-point shall be no less than that during the most recent performance test that demonstrated that the facility was in compliance.

4.5.2.10 For catalytic incinerators, all 3-hour periods of operation in which the average temperature of the process vent stream immediately before the catalyst bed is more than 28°C (50°F) below the average temperature of the process vent stream immediately before the catalyst bed during the most recent performance test that demonstrated that the facility was in compliance. The set-point for the process vent stream immediately before the catalyst bed shall be no less than that during the most recent performance test that demonstrated that the facility was in compliance.

4.5.2.11 For carbon adsorbers, all three-hour periods of operation during which either the average VOC concentration or the reading of organics in the exhaust gases is more than 20% greater than the average exhaust gas concentration or reading measured by the organics monitoring device during the most recent determination of the recovery efficiency of the carbon adsorber that demonstrated that the facility was in compliance.

4.5.3 Reporting. On and after November 15, 1993, the owner or operator of a subject coating unit, line, or operation referenced in 4.5 of this regulation shall notify the Department in either of the following instances:

4.5.3.1 Any record showing noncompliance with the applicable requirements for control devices shall be reported by sending a copy of the record to the Department within 45 calendar days following the occurrence.

4.5.3.2 At least 30 calendar days before changing the method of compliance from control devices to the use of complying coatings or daily-weighted averaging, the owner or operator shall comply with all requirements of 4.3.1 or 4.4.1 of this regulation, respectively, as well as 7 DE Admin. Code 1102. Upon changing the method of compliance from control devices to the use of complying coatings or daily-weighted averaging, the owner or operator shall comply with all requirements of the section of this regulation applicable to the coating unit, line, or operation referenced in 4.5 of this regulation.

01/11/1993

5.1 Initial compliance certification. The owner or operator of any facility containing sources subject to 5.0 of this regulation shall submit to the Department an initial compliance certification by November 15, 1993. The owner or operator of any new facility containing sources that become subject to 5.0 of this regulation after November 15, 1992 shall submit an initial compliance certification immediately upon startup of the facility.

5.1.1 The initial compliance certification shall provide at a minimum the following information:

5.1.1.1 The name and location of the facility.

5.1.1.2 The address and telephone number of the person responsible for the facility.

5.1.1.3 Identification of subject sources.

5.1.2 For each subject source, the initial compliance certification shall also provide at a minimum:

5.1.2.1 The applicable emission limitation, equipment specification, or work practice.

5.1.2.2 The method of compliance.

5.1.2.3 For each source subject to numerical emission limitations of this regulation, the estimated emissions without control.

5.1.2.4 The control system or systems in use.

5.1.2.5 The design performance efficiency of the control system.

5.1.2.6 For each source subject to numerical emission limitations of this regulation, the estimated emissions after control.

5.1.2.7 Certification that each subject source at the facility is in compliance with the applicable emission limitation, equipment specification, or work practice.

5.1.2.8 The time at which the facility's "day" begins if a time other than midnight local time is used to define a "day."

5.2 Reports of excess emissions. The owner or operator of any facility containing sources subject to 5.0 of this regulation shall, for each occurrence of excess emissions, within 30 calendar days of becoming aware of such occurrence, supply the Department with the following information, in addition to complying with any other reporting requirements mandated by the State of Delaware:

5.2.1 The name and location of the facility.

5.2.2 The subject sources that caused the excess emissions.

5.2.3 The time and date of first observation of the excess emissions.

5.2.4 The cause and expected duration of the excess emissions.

5.2.5 For sources subject to numerical emission limitations, the estimated rate of emissions (expressed in the units of the applicable emission limitation) and the operating data and calculations used in determining the magnitude of the excess emissions.

5.2.6 The proposed corrective actions and schedule to correct the conditions causing the excess emissions.

5.3 Requirements for sources using control devices.

5.3.1 Testing of control equipment. By November 15, 1993, or upon startup of a new source, or upon changing the method of compliance for an existing source, the owner or operator of the subject source shall perform all tests and submit to the Department the results of all tests and calculations necessary to demonstrate that the subject source will be in compliance with the applicable section of this regulation on and after November 15, 1993, or on and after the initial startup date.

5.3.2 Recordkeeping.

5.3.2.1 Each owner or operator of a source subject to 5.0 of this regulation shall maintain up-to-date, readily accessible continuous records of any equipment operating parameters specified to be monitored in the applicable section of this regulation as well as up-to-date, readily accessible records of periods of operation during which the parameter boundaries established during the most recent performance test are exceeded. These records shall be maintained for at least five years. The Department may at any time require a report of these data. Periods of operation during which the parameter boundaries established during the most recent performance tests are exceeded are defined as follows:

5.3.2.1.1 For thermal incinerators, all three-hour periods of operation in which the average combustion temperature was more than 28°C (50°F) below the average combustion temperature during the most recent performance test that demonstrated that the facility was in compliance. The combustion chamber set-point shall be no less than that during the most recent performance test that demonstrated that the facility was in compliance.

5.3.2.1.2 For catalytic incinerators, all three-hour periods of operation in which the average temperature of the process vent stream immediately before the catalyst bed is more than 28°C (50°F) below the average temperature of the process vent stream immediately before the catalyst bed during the most recent performance test that demonstrated that the facility was in compliance. The set-point for the process vent stream immediately before the catalyst bed shall be no less than that during the most recent performance test that demonstrated that the facility was in compliance.

5.3.2.1.3 For carbon adsorbers, all three-hour periods of operation during which either the average VOC concentration or the reading of organics in the exhaust gases is more than 20% greater than the average exhaust gas concentration or reading measured by the organics monitoring device during the most recent determination of the recovery efficiency of the carbon adsorber that demonstrated that the facility was in compliance.

5.3.2.2 A log of operating time for the capture system, control device, monitoring equipment, and the associated source.

5.3.2.3 A maintenance log for the capture system, control device, and monitoring equipment detailing all routine and non-routine maintenance performed including dates and duration of any outages.

01/11/1993

Each owner or operator of a source subject to this regulation shall maintain all records necessary for determining compliance with this regulation at the facility for a period of five years.

7.1 No owner or operator subject to this regulation may build, erect, install, or use any article, machine, equipment, process, or other method the use of which conceals emissions that would otherwise constitute non-compliance with an applicable section of this regulation.

7.2 7.1 of this regulation includes, but is not limited to, the use of gaseous diluents to achieve compliance, and the piecemeal carrying out of an operation to avoid coverage by a section of this regulation that applies only to operations larger than a specified size.

7.3 No owner or operator of a facility subject to this regulation shall discharge or dispose of VOCs or material containing VOCs to surface impoundments, pits, wastewater treatment facilities or sewers for the purpose of circumventing any provision or requirement of this regulation.

03/11/11

8.1 Except as provided for in 8.3 of this regulation, the requirements of 8.0 of this regulation apply to any facility that is subject to any of the requirements of 10.0 through 50.0 of this regulation, and any facility that emits at least 6.8 kg/day (15 lb/day) of VOC before consideration of controls.

8.2 Definitions

"Cleanup solvent" means a VOC-containing material used to remove any loosely held uncured (i.e., not dry to the touch) adhesive or sealant that is subject to 4.0 of 7 DE Admin. Code 1141 from a substrate, or to clean equipment used in applying an adhesive or sealant subject to 4.0 of 7 DE Admin. Code 1141.

"Electrical and electronic components" means components and assemblies of components that generate, convert, transmit, or modify electrical energy. Electrical and electronic components include, but are not limited to, wires, windings, stators, rotors, magnets, contacts, relays, printed circuit boards, printed wire assemblies, wiring boards, integrated circuits, resistors, capacitors and transistors. Cabinets in which electrical and electronic components are housed are not considered electrical and electronic components.

"Flushing" means pumping a solvent from a reservoir through a pipe or hose or through equipment (e.g., pipes, hoses, tanks) to remove contaminants or residue.

"Hand-wiping" means a method of cleaning a surface by physically rubbing it with a material such as a rag, paper, sponge or a cotton swab moistened with a solvent.

"Medical device" means an instrument, apparatus, implement, machine, contrivance, implant, in vitro reagent or other similar article, including any component or accessory that is, (i) intended for use in the diagnosis of disease or other conditions, or in the cure, mitigation, treatment, or prevention of diseases, or (ii) is intended to affect the structure or any function of the body, or (iii) is defined in the National Formulary or the United States Pharmacopoeia or any supplement to it.

"Non-manufacturing area cleaning" means the cleaning of cafeterias, laboratories, pilot facilities, restrooms, office buildings, etc.

"Medical Device and Pharmaceutical Manufacturing" means Medical devices; pharmaceutical products; and associated manufacturing and product handling equipment and material, work surfaces, maintenance tools and room surfaces that are subject to US FDA current Good Manufacturing/Laboratory Practice, or CDC/NIH guidelines for biological disinfection of surfaces.

“Pharmaceutical product” means a preparation or compound, which includes any drug, analgesic, decongestant, antihistamine, cough suppressant, vitamin, mineral or herb supplement intended for human or animal consumption and used to cure, mitigate or treat disease or improve or enhance health.

"Precision optics" means the optical elements used in electro-optical devices that are designed to sense, detect, or transmit light energy, including specific wavelengths of light energy and changes of light energy levels.

"Solvent Cleaning Operation" means the removal of uncured adhesives, inks, coatings, or contaminants including dirt, soil, and grease from parts, products, tools, machinery, equipment, and general work areas. Solvent cleaning operations include hand-wiping, surface preparation, flushing and the cleaning of spray guns/cleaning of equipment used to spray coatings, adhesives, etc.

"Stripping" means the removal of cured coatings, cured inks, or cured adhesives.

"Surface preparation" means the removal of contaminants such as dust, soil, oil, grease, etc., prior to coating, adhesive, or ink applications.

"Surface preparation solvent" means a solvent used to remove dirt, oil and other contaminants from a substrate prior to the application of a primer, adhesive or sealant that is subject to 4.0 of 7 DE Admin. Code 1141.

8.3 Exemptions.

8.3.1 The requirements of 8.0 this regulation do not apply to any equipment or operation that is specifically subject to the emission limitations of 10.0, 11.0 or 38.0 of this regulation; or to any piece of equipment that is specifically subject to the requirements of 33.0 of this regulation.

8.3.2 Existing sources affected by 8.0 of this regulation shall comply with the provisions of 8.0 of this regulation on and after March 11, 2011, except for the requirements of 8.5 of this regulation. Existing sources affected by 8.5 of this regulation shall comply with the requirements of 8.5 of this regulation beginning as soon as practical, but no later than March 11, 2012. New, modified, or reconstructed sources affected by 8.0 of this regulation shall comply with the provisions of 8.0 of this regulation on and after startup.

8.3.3 The requirements of 8.5 of this regulation shall not apply to any facility subject to 47.0 of this regulation, or to:

8.3.3.1 The surface preparation or cleaning of electrical and electronic components;

8.3.3.2 The surface preparation or cleaning of precision optics;

8.3.3.3 The surface preparation or cleaning of numismatic dies;

8.3.3.4 Stripping of cured inks, coatings, and adhesives;

8.3.3.5 The cleaning of resin, coating, ink, and adhesive mixing, molding, and application equipment;

8.3.3.6 Surface preparation associated with research and development activities;

8.3.3.7 Surface preparation associated with medical device and pharmaceutical manufacturing;

8.3.3.8 Cleaning associated with performance or quality assurance testing of coatings, inks, or adhesives involved;

8.3.3.9 Non-manufacturing area cleaning, and

8.3.3.10 The use of any surface preparation solvent or cleanup solvent subject to 4.0 of 7 DE Admin. Code 1141.

8.4 Work Practice Standards.

8.4.1 No owner or operator of a facility subject to 8.4 of this regulation may cause, allow, or permit the disposal of more than five kilograms (kg) (11 pounds [lb]) of any VOC, or of any materials containing more than five kg (11 lb) of any VOCs, at that facility in any one day in a manner that would permit the evaporation of VOC into the ambient air. This provision does not apply to:

8.4.1.1 Any VOC or material containing VOC emitted from a regulated entity that is subject to a VOC standard under this regulation.

8.4.1.2 Coating sources that are exempt from the emission limitations of 10.0 through 23.0 of this regulation.

8.4.1.3 Waste paint (sludge) handling systems, water treatment systems, and other similar operations at coating facilities using complying coatings.

8.4.1.4 Any VOC or material containing VOCs used during process maintenance turnarounds for cleaning purposes, provided that the provisions of 8.4.3, 8.4.4, 8.4.5 and 8.4.6 of this regulation are followed.

8.4.2 The requirements of 8.4.1 of this regulation includes, but are not limited to, the disposal of VOC from VOC control devices.

8.4.3 No owner or operator of a facility subject to 8.4 of this regulation shall use open containers for the storage or disposal of cloth or paper impregnated with VOCs. Containers for the storage or disposal of cloth or paper impregnated with VOCs shall be kept closed, except when adding or removing material.

8.4.4 No owner or operator of a facility subject to 8.4 of this regulation shall store in open containers spent or fresh VOC or VOC containing material. Containers for the storage of spent or fresh VOCs or VOC containing material shall be kept closed, except when adding or removing material.

8.4.5 No owner or operator of a facility subject to 8.4 of this regulation shall use VOC for the cleanup of spray equipment unless one or more of the following methods are used to collect the cleaning compounds and to minimize their evaporation to the atmosphere.

8.4.5.1 Use of an enclosed spray gun cleaning system that is kept closed when not in use.

8.4.5.2 Non-atomized discharge of solvent into a waste container that is kept closed when not in use.

8.4.5.3 Disassembly of the spray gun and cleaning in a vat that is kept closed when not in use.

8.4.5.4 Atomized spray into a waste container that is fitted with a device that captures atomized solvent emissions.

8.4.5.5 Any alternative technique that has been demonstrated to, and accepted by the Department as producing emissions that are equal to or less than the emissions from the techniques specified in 8.4.5.1 through 8.4.5.4 of this regulation. Emissions from any alternative technique shall be demonstrated pursuant to test protocols that are approved in advance by the Department.

8.4.6 Any owner or operator of a facility subject to 8.4 of this regulation shall:

8.4.6.1 Convey VOC-containing cleaning materials from one location to another in closed containers or pipes.

8.4.6.2 Handle and transfer all fresh and spent cleaning solvent and other VOC-containing material to or from any container, tank, vat, vessel, mixing vessel, or piping system, etc. in such a manner that minimizes spills and other losses.

8.4.6.3 Clean up spills of fresh and spent cleaning solvent and other VOC-containing material immediately.

8.4.7 Any owner or operator of a facility subject to 8.4 of this regulation shall minimize air circulation around cleaning operations and shall implement equipment practices that minimize emissions including keeping part cleaners covered when not in use, and maintaining cleaning equipment to repair solvent leaks.

8.5 Control Requirements. No owner or operator of a facility subject to 8.5 of this regulation shall use any liquid VOC containing material for any solvent cleaning operation that does not meet one of the requirements of 8.5.1 through 8.5.3.

8.5.1 The VOC content is equal to or less than 50 grams VOC per liter (0.42 1b/gal), as applied, or

8.5.2 The VOC composite vapor pressure is equal to or less than 8 millimeters of mercury (mmHg) at 20 degrees Celsius (20°C), as applied, or

8.5.3 The emissions of that material are controlled by an emission control system that:

8.5.3.1 Achieves an overall control efficiency of equal to or greater than 85 percent, by weight, or

8.5.3.2 Maintains a maximum outlet total organic carbon concentration of 20 parts per million by volume (ppmv) as carbon (C1) on a dry basis.

8.6 Test Methods and Procedures.

8.6.1 Any owner or operator subject to 8.5.1 of this regulation shall determine the VOC content of each cleaning solution using the test methods and procedures specified in Appendix A and Appendix B of this regulation, or using the manufacturer's product formulation data, and the following equation:

VOC Content (in grams per liter of material) = (WS -WW -Wes)/Vm

(8-1)

Where:

WS = Weight of volatile compounds in grams(g);

WW = Weight of water, in g;

Wes = Weight of exempt compounds in g;

Vm = Volume of material in liters

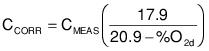

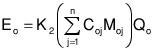

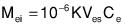

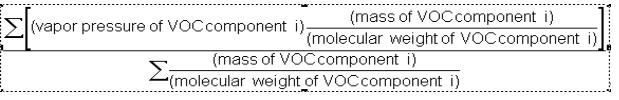

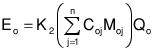

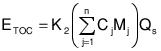

8.6.2 Any owner or operator subject to 8.5.2 of this regulation shall determine the VOC composite vapor pressure of each cleaning solution using the test methods and procedures specified in Appendix A and Appendix B of this regulation, or using the manufacturer's product formulation data, and the following equation:

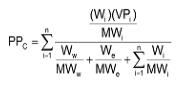

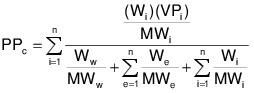

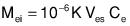

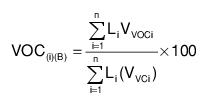

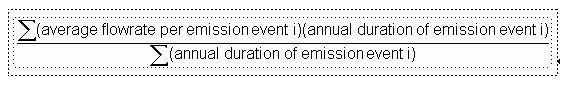

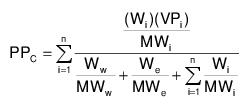

(8-2)

Where:

Wi = Weight of the ith VOC compound, in grams (g);

Ww = Weight of water, in g;

We = Weight of exempt compound, in g;

MWi = Molecular weight of the ith VOC compound, in grams per gram-mole

MWw = Molecular weight of water, in grams per gram-mole

MWe = Molecular weight of exempt compound, in grams per gram-mole;

PPc= VOC composite partial pressure at 20°C, in mmHg

VPi = Vapor pressure of the ith VOC compound at 20°C, in mmHg

8.6.3 Any owner or operator subject to 8.5.3 of this regulation shall conduct an initial test to demonstrate the efficiency of each emission control system using the applicable test methods and procedures specified in Appendix A through Appendix E of this regulation. The cleaning operation shall operate at maximum operating conditions and flow rates during any emission testing.

8.7 Recordkeeping. Any owner or operator subject to 8.5 of this regulation shall maintain all of the information necessary for the Department to determine compliance with the applicable requirements of 8.5 of this regulation. Such information shall be made available to the Department upon verbal or written request, and shall be maintained for a minimum of five years from the date such record is created. Information sufficient to determine compliance shall include, but is not limited to the following:

8.7.1 Name and quantity of each cleaning solvent used,

8.7.2 VOC content or vapor pressure of each cleaning solvent, as applied,

8.7.3 Material Safety Data Sheets for all cleaning solvents used,

8.7.4 Documentation of air pollution control equipment efficiency or capture efficiency, if applicable,

8.7.5 Date and type of maintenance performed on air pollution control or capture equipment, if applicable, and

8.7.6 Quantity of non-compliant solvent used, in gallons, for each day, each week, and calendar year.

01/11/1993

9.1 Compliance with the provisions of this regulation is required immediately upon promulgation.

9.2 Permits. After the effective date of this regulation, no owner or operator shall construct, modify or operate any source subject to this regulation without first obtaining a permit for such construction, modification or operation pursuant to the provisions of 7 DE Admin. Code 1102.

9.3 Compliance Programs and Schedules. For sources as a result of this regulation that are required to make major process changes or major capital expenditures, as determined by the Department, an acceptable program to comply with this regulation shall be developed and submitted to the Department by the owner or operator of such source within 180 days of the effective date of the regulation. The program shall include the dates for ordering, receiving, installation and startup of necessary equipment. All such programs shall contain a schedule and timetable for compliance certification, including increments of progress which will require compliance with the applicable requirements as expeditiously as practicable, but not later than the date specified in the applicable requirement. [Note: For federal purposes and for federal enforcement, no such program approved by the Department shall be federally-approved pursuant to the Clean Air Act until the Administrator of the U.S. EPA determines that such program was approved in accordance with these requirements, or within the applicable provisions of the Federal Clean Air Act, and any such program approved by the Department shall cease to be federally approved upon a determination by the Administrator of the U.S. EPA that it was not issued in accordance with the applicable provisions of the Federal Clean Air Act].

9.4 Enforceability. For the purpose of federal enforceability of the provisions of this regulation, references to the Department shall also mean the Administrator of the U.S. EPA.

02/11/2003

10.1 Applicability

10.1.1 Except as provided for in 10.1.2 and 10.1.3 of this regulation, 10.0 of this regulation applies to any owner or operator of any aerospace manufacturing or rework facility that conducts any of the following operation or operations:

10.1.1.1 hand-wipe cleaning;

10.1.1.2 spray gun cleaning;

10.1.1.3 flush cleaning;

10.1.1.4 primer, topcoat, self-priming topcoat, and specialty coating application;

10.1.1.5 the depainting of the outer surface of aerospace vehicles (except for depainting parts or units normally removed during depainting);

10.1.1.6 Type I or Type II chemical milling maskant application; and

10.1.1.7 VOC handling and storage.

10.1.2 Except for the requirements in 10.3.8 of this regualtion, 10.0 of this regulation does not apply to the following operations in any aerospace manufacturing or rework facility:

10.1.2.1 Chemical milling;

10.1.2.2 Metal finishing;

10.1.2.3 Electrodeposition (except for the electrodeposition of paints); and