|

|

Authenticated PDF Version Authenticated PDF Version

Section 266.20 Applicability.

(1) Without mixing with any other substance(s); or

(2) After mixing or in combination with any other substance(s). These materials will be referred to throughout this subpart as "materials used in a manner that constitutes disposal".

Section 266.21 Standards applicable to generators and transporters of materials used in a manner that constitute disposal.

Section 266.22 Standards applicable to storers of materials that are to be used in a manner that constitutes disposal who are not the ultimate users.

Section 266.23 Standards applicable to users of materials that are used in a manner that constitutes disposal.

(Amended November 21, 1985; August 29, 1988, July 23, 1996)

Section 266.70 Applicability and requirements.

(1) Notification requirements under 7 Del.C., Chapter 63;

(2) Subpart B of Part 262 of these regulations (for generators), §263.20 and §263.21 of these regulations (for transporters), and §265.71 and §265.72 of these regulations (for persons who store) of these regulations; and

(3) For precious metals exported to or imported from other countries for recovery, Part 262, Subpart H and §265.12 of these regulations.

(1) Records showing the volume of these materials stored at the beginning of the calendar year;

(2) The amount of these materials generated or received during the calendar year; and

(3) The amount of materials remaining at the end of the calendar year.

Section 266.80 Applicability and requirements.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

are exempt from Parts 262 (except for §262.11, §262.18, and Subpart H), 263, 264, 265, 266, 268, 122, 124 of these regulations, and the notification requirements at sections 6306 and 6307 of Del.C., Chapter 63.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(i) Notification requirements under 6307 of Del.C., Chapter 63.

(ii) All applicable provisions in Subpart A of Part 265 of these regulations.

(iii) All applicable provisions in Subpart B of Part 265 of these regulations except §265.13 (waste analysis).

(iv) All applicable provisions in Subparts C and D of Part 265 of these regulations.

(v) All applicable provisions in Subpart E of Part 265 of these regulations except §§ 265.71 and 265.72 (dealing with the use of the manifest and manifest discrepancies).

(vi) All applicable provisions in Subparts F through L of Part 265 of these regulations.

(vii) All applicable provisions in Parts 122 and 124 of these regulations.

(i) Notification requirements under 6307 of Del.C., Chapter 63.

(ii) All applicable provisions in Subpart A of Part 264 of these regulations.

(iii) All applicable provisions in Subpart B of Part 264 of these regulations but not §264.13 (waste analysis).

(iv) All applicable provisions in Subparts C and D of Part 264 of these regulations.

(v) All applicable provisions in Subpart E of Part 264 of these regulations but not §264.71 or §264.72 (dealing with the use of the manifest and manifest discrepancies).

(vi) All applicable provisions in Subparts F through L of Part 264 of these regulations.

(vii) All applicable provisions in Parts 122 and 124 of these regulations.

(Amended November 21, 1985, August 29, 1988, July 23, 1996, June 2, 2000)

14 DE Reg. 668 (01/01/11)

24 DE Reg. 711 (01/01/21)

Section 266.100 Applicability.

(1) Except as provided by paragraph (b)(2) of this section, the standards of this part no longer apply when an affected source demonstrates compliance with the maximum achievable control technology (MACT) requirements of 40 CFR Part 63, Subpart EEE, by conducting a comprehensive performance test and submitting to the EPA Administrator, with a copy to the DNREC Solid and Hazardous Waste Management Section, a Notification of Compliance under 40 CFR §§ 63.1207(j) and 63.1210(d) documenting compliance with the requirements of 40 CFR Part 63, Subpart EEE. Nevertheless, even after this demonstration of compliance with the MACT standards, DNREC hazardous waste permit conditions that were based on the standards of this part will continue to be in effect until they are removed from the permit or the permit is terminated or revoked, unless the permit expressly provides otherwise.

(2) The following standards continue to apply:

(i) The closure requirements of §§ 266.102(e)(11) and 266.103(l);

(ii) The standards for direct transfer of §266.111;

(iii) The standards for regulation of residues of §266.112; and

(iv) The applicable requirements of Subparts A through H, BB and CC of Parts 264 and 265 of these regulations.

(1) Used oil burned for energy recovery that is also a hazardous waste solely because it exhibits a characteristic of hazardous waste identified in Subpart C of Part 261 of these regulations. Such used oil is subject to regulation under Part 279 of these regulations;

(2) Gas recovered from hazardous or solid waste landfills when such gas is burned for energy recovery;

(4) Coke ovens, if the only hazardous waste burned is EPA Hazardous Waste No. K087, decanter tank tar sludge from coking operations.

(i) Provide a one-time written notice to the Secretary indicating the following:

(A) The owner or operator claims exemption under this paragraph;

(B) The hazardous waste is burned solely for metal recovery consistent with the provisions of paragraph (d)(2) of this section;

(C) The hazardous waste contains recoverable levels of metals; and

(D) The owner or operator will comply with the sampling and analysis and recordkeeping requirements of this paragraph;

(ii) Sample and analyze the hazardous waste and other feedstocks as necessary to comply with the requirements of this paragraph by using appropriate methods; and

(iii) Maintain at the facility for at least three years records to document compliance with the provisions of this paragraph including limits on levels of toxic organic constituents and Btu value of the waste, and levels of recoverable metals in the hazardous waste compared to normal nonhazardous waste feedstocks.

(2) A hazardous waste meeting either of the following criteria is not processed solely for metal recovery:

(i) The hazardous waste has a total concentration of organic compounds listed in Part 261, Appendix VIII, of these regulations exceeding 500 ppm by weight, as-fired, and so is considered to be burned for destruction. The concentration of organic compounds in a waste as-generated may be reduced to the 500 ppm limit by bona fide treatment that removes or destroys organic constituents. Blending for dilution to meet the 500 ppm limit is prohibited and documentation that the waste has not been impermissibly diluted must be retained in the records required by paragraph (d)(1)(iii) of this section; or

(ii) The hazardous waste has a heating value of 5,000 Btu/lb or more, as-fired, and so is considered to be burned as fuel. The heating value of a waste as-generated may be reduced to below the 5,000 Btu/lb limit by bona fide treatment that removes or destroys organic constituents. Blending for dilution to meet the 5,000 Btu/lb limit is prohibited and documentation that the waste has not been impermissibly diluted must be retained in the records required by paragraph (d)(1)(iii) of this section.

(3) To be exempt from §§ 266.102 through 266.111, an owner or operator of a lead or nickel-chromium or mercury recovery furnace (except for owners or operators of lead recovery furnaces subject to regulation under the Secondary Lead Smelting NESHAP) must provide a one-time written notice to the Secretary identifying each hazardous waste burned and specifying whether the owner or operator claims an exemption for each waste under this paragraph or paragraph (d)(1) of this section. The owner or operator must comply with the requirements of paragraph (d)(1) of this section for those wastes claimed to be exempt under that paragraph and must comply with the requirements below for those wastes claimed to be exempt under this paragraph (d)(3).

(i) The hazardous wastes listed in Appendices XI, XII, and XIII, Part 266, and baghouse bags used to capture metallic dusts emitted by steel manufacturing are exempt from the requirements of paragraph (d)(1) of this section, provided that:

(A) A waste listed in Appendix XI of this part must contain recoverable levels of lead, a waste listed in Appendix XII of this part must contain recoverable levels of nickel or chromium, a waste listed in Appendix XIII of this part must contain recoverable levels of mercury and contain less than 500 ppm of Part 261, Appendix VIII organic constituents, and baghouse bags used to capture metallic dusts emitted by steel manufacturing must contain recoverable levels of metal; and

(B) The waste does not exhibit the Toxicity Characteristic of §261.24 of these regulations for an organic constituent; and

(C) The waste is not a hazardous waste listed in Subpart D of Part 261 of these regulations because it is listed for an organic constituent as identified in Appendix VII of Part 261 of these regulations; and

(D) The owner or operator certifies in the one-time notice that hazardous waste is burned under the provisions of paragraph (d)(3) of this section and that sampling and analysis will be conducted or other information will be obtained as necessary to ensure continued compliance with these requirements. Sampling and analysis shall be conducted according to paragraph (d)(1)(ii) of this section and records to document compliance with paragraph (d)(3) of this section shall be kept for at least three years.

(ii) The Secretary may decide on a case-by-case basis that the toxic organic constituents in a material listed in Appendix XI, XII, or XIII of this part that contains a total concentration of more than 500 ppm toxic organic compounds listed in Appendix VIII, Part 261 of these regulations, may pose a hazard to human health and the environment when burned in a metal recovery furnace exempt from the requirements of this subpart. In that situation, after adequate notice and opportunity for comment, the metal recovery furnace will become subject to the requirements of this subpart when burning that material. In making the hazard determination, the Secretary will consider the following factors:

(A) The concentration and toxicity of organic constituents in the material; and

(B) The level of destruction of toxic organic constituents provided by the furnace; and

(C) Whether the acceptable ambient levels established in Appendices IV or V of this part may be exceeded for any toxic organic compound that may be emitted based on dispersion modeling to predict the maximum annual average off-site ground level concentration.

(g) Owners and operators of smelting, melting, and refining furnaces (including pyrometallurgical devices such as cupolas, sintering machines, roasters, and foundry furnaces) that process hazardous waste for recovery of economically significant amounts of the precious metals gold, silver, platinum, palladium, iridium, osmium, rhodium, or ruthenium, or any combination of these are conditionally exempt from regulation under this subpart, except for §266.112. To be exempt from §§ 266.101 through 266.111, an owner or operator must:

(1) Provide a one-time written notice to the Secretary indicating the following:

(i) The owner or operator claims exemption under this paragraph;

(ii) The hazardous waste is burned for legitimate recovery of precious metal; and

(iii) The owner or operator will comply with the sampling and analysis and recordkeeping requirements of this paragraph; and

(2) Sample and analyze the hazardous waste as necessary to document that the waste contains economically significant amounts of the metals and that the treatment recovers economically significant amounts of precious metal; and

(3) Maintain at the facility for at least three years records to document that all hazardous wastes burned are burned for recovery of economically significant amounts of precious metal.

(h) Starting June 23, 1997, owners or operators of lead recovery furnaces that process hazardous waste for recovery of lead and that are subject to regulation under the Secondary Lead Smelting NESHAP, are conditionally exempt from regulation under this subpart, except for §266.101. To be exempt, an owner or operator must provide a one-time notice to the Secretary identifying each hazardous waste burned and specifying that the owner or operator claims an exemption under this paragraph. The notice also must state that the waste burned has a total concentration of non-metal compounds listed in Part 261, Appendix VIII, of these regulations of less than 500 ppm by weight, as fired and as provided in paragraph (d)(2)(i) of this section, or is listed in Appendix XI, Part 266.

22 DE Reg. 678 (02/01/19)

Section 266.101 Management prior to burning.

(1) Owners and operators of facilities that store or treat hazardous waste that is burned in a boiler or industrial furnace are subject to the applicable provisions of Parts 264, 265, and 122 of these regulations, except as provided by paragraph (c)(2) of this section. These standards apply to storage and treatment by the burner as well as to storage and treatment facilities operated by intermediaries (processors, blenders, distributors, etc.) between the generator and the burner.

(2) Owners and operators of facilities that burn, in an on-site boiler or industrial furnace exempt from regulation under the small quantity burner provisions of §266.108, hazardous waste that they generate are exempt from the regulations of Parts 264, 265, and 122 of these regulations applicable to storage units for those storage units that store mixtures of hazardous waste and the primary fuel to the boiler or industrial furnace in tanks that feed the fuel mixture directly to the burner. Storage of hazardous waste prior to mixing with the primary fuel is subject to regulation as prescribed in paragraph (c)(1) of this section.

24 DE Reg. 711 (01/01/21)

Section 266.102 Permit standards for burners.

(1) General. Owners and operators of boilers and industrial furnaces burning hazardous waste and not operating under interim status must comply with the requirements of this section and §§122.22 and 122.66 of these regulations, unless exempt under the small quantity burner exemption of §266.108.

(2) Applicability of Part 264 standards. Owners and operators of boilers and industrial furnaces that burn hazardous waste are subject to the following provisions of Part 264 of these regulations, except as provided otherwise by this subpart:

(i) In Subpart A (General), 264.4;

(ii) In Subpart B (General facility standards), §§ 264.11-264.18;

(iii) In Subpart C (Preparedness and prevention), §§ 264.31-264.37;

(iv) In Subpart D (Contingency plan and emergency procedures), §§ 264.51-264.56;

(v) In Subpart E (Manifest system, recordkeeping, and reporting), the applicable provisions of §§ 264.71-264.77;

(vi) In Subpart F (Releases from Solid Waste Management Units), §§ 264.90 and 264.101;

(vii) In Subpart G (Closure and post-closure), §§ 264.111-264.115;

(viii) In Subpart H (Financial requirements), §§ 264.141, 264.142, 264.143, and 264.147-264.151, except that States and the Federal government are exempt from the requirements of Subpart H; and

(ix) Subpart BB (Air emission standards for equipment leaks), except §§ 264.1050(a).

(1) The owner or operator must provide an analysis of the hazardous waste that quantifies the concentration of any constituent identified in Appendix VIII of Part 261 of these regulations that may reasonably be expected to be in the waste. Such constituents must be identified and quantified if present, at levels detectable by using appropriate analytical procedures. The Appendix VIII, Part 261 constituents excluded from this analysis must be identified and the basis for their exclusion explained. This analysis will be used to provide all information required by this subpart and §122.22 and §122.66 of these regulations and to enable the permit writer to prescribe such permit conditions as necessary to protect human health and the environment. Such analysis must be included as a portion of the Part B permit application, or, for facilities operating under the interim status standards of this subpart, as a portion of the trial burn plan that may be submitted before the Part B application under provisions of §122.66(g) of these regulations as well as any other analysis required by the permit authority in preparing the permit. Owners and operators of boilers and industrial furnaces not operating under the interim status standards must provide the information required by §§ 122.22 or 122.66(c) of these regulations in the Part B application to the greatest extent possible.

(2) Throughout normal operation, the owner or operator must conduct sampling and analysis as necessary to ensure that the hazardous waste, other fuels, and industrial furnace feedstocks fired into the boiler or industrial furnace are within the physical and chemical composition limits specified in the permit.

(1) The owner or operator may burn only hazardous wastes specified in the facility permit and only under the operating conditions specified under paragraph (e) of this section, except in approved trial burns under the conditions specified in §122.66 of these regulations.

(2) Hazardous wastes not specified in the permit may not be burned until operating conditions have been specified under a new permit or permit modification, as applicable. Operating requirements for new wastes may be based on either trial burn results or alternative data included with Part B of a permit application under §122.22 of these regulations.

(3) Boilers and industrial furnaces operating under the interim status standards of §266.103 are permitted under procedures provided by §122.66(g) of these regulations.

(4) A permit for a new boiler or industrial furnace (those boilers and industrial furnaces not operating under the interim status standards) must establish appropriate conditions for each of the applicable requirements of this section, including but not limited to allowable hazardous waste firing rates and operating conditions necessary to meet the requirements of paragraph (e) of this section, in order to comply with the following standards:

(i) For the period beginning with initial introduction of hazardous waste and ending with initiation of the trial burn, and only for the minimum time required to bring the device to a point of operational readiness to conduct a trial burn, not to exceed a duration of 720 hours operating time when burning hazardous waste, the operating requirements must be those most likely to ensure compliance with the emission standards of §§ 266.104 through 266.107, based on the Secretary's engineering judgment. If the applicant is seeking a waiver from a trial burn to demonstrate conformance with a particular emission standard, the operating requirements during this initial period of operation shall include those specified by the applicable provisions of §266.104, §266.105, §266.106, or §266.107. The Secretary may extend the duration of this period for up to 720 additional hours when good cause for the extension is demonstrated by the applicant.

(ii) For the duration of the trial burn, the operating requirements must be sufficient to demonstrate compliance with the emissions standards of §§ 266.104 through 266.107 and must be in accordance with the approved trial burn plan;

(iii) For the period immediately following completion of the trial burn, and only for the minimum period sufficient to allow sample analysis, data computation, submission of the trial burn results by the applicant, review of the trial burn results and modification of the facility permit by the Secretary to reflect the trial burn results, the operating requirements must be those most likely to ensure compliance with the emission standards §§ 266.104 through 266.107 based on the Secretary's engineering judgment.

(iv) For the remaining duration of the permit, the operating requirements must be those demonstrated in a trial burn or by alternative data specified in §122.22 of these regulations, as sufficient to ensure compliance with the emissions standards of §§ 266.104 through 266.107.

(1) General. A boiler or industrial furnace burning hazardous waste must be operated in accordance with the operating requirements specified in the permit at all times where there is hazardous waste in the unit.

(2) Requirements to ensure compliance with the organic emissions standards-

(i) DRE standard. Operating conditions will be specified either on a case-by-case basis for each hazardous waste burned as those demonstrated (in a trial burn or by alternative data as specified in §122.22) to be sufficient to comply with the destruction and removal efficiency (DRE) performance standard of §266.104(a) or as those special operating requirements provided by §266.104(a)(4) for the waiver of the DRE trial burn. When the DRE trial burn is not waived under §266.104(a)(4), each set of operating requirements will specify the composition of the hazardous waste (including acceptable variations in the physical and chemical properties of the hazardous waste which will not affect compliance with the DRE performance standard) to which the operating requirements apply. For each such hazardous waste, the permit will specify acceptable operating limits including, but not limited to, the following conditions as appropriate:

(A) Feed rate of hazardous waste and other fuels measured and specified as prescribed in paragraph (e)(6) of this section;

(B) Minimum and maximum device production rate when producing normal product expressed in appropriate units, measured and specified as prescribed in paragraph (e)(6) of this section;

(C) Appropriate controls of the hazardous waste firing system;

(D) Allowable variation in boiler and industrial furnace system design or operating procedures;

(E) Minimum combustion gas temperature measured at a location indicative of combustion chamber temperature, measured and specified as prescribed in paragraph (e)(6) of this section;

(F) An appropriate indicator of combustion gas velocity, measured and specified as prescribed in paragraph (e)(6) of this section, unless documentation is provided under §122.66 of these regulations demonstrating adequate combustion gas residence time; and

(G) Such other operating requirements as are necessary to ensure that the DRE performance standard of §266.104(a) is met.

(ii) Carbon monoxide and hydrocarbon standards. The permit must incorporate a carbon monoxide (CO) limit and, as appropriate, a hydrocarbon (HC) limit as provided by paragraphs (b), (c), (d), (e) and (f) of §266.104. The permit limits will be specified as follows:

(A) When complying with the CO standard of §266.104(b)(1), the permit limit is 100 ppmv;

(B) When complying with the alternative CO standard under §266.104(c), the permit limit for CO is based on the trial burn and is established as the average over all valid runs of the highest hourly rolling average CO level of each run, and the permit limit for HC is 20 ppmv (as defined in §266.104(c)(1)), except as provided in §266.104(f).

(C) When complying with the alternative HC limit for industrial furnaces under §266.104(f), the permit limit for HC and CO is the baseline level when hazardous waste is not burned as specified by that paragraph.

(iii) Start-up and shut-down. During start-up and shut-down of the boiler or industrial furnace, hazardous waste (except waste fed solely as an ingredient under the Tier I (or adjusted Tier I) feed rate screening limits for metals and chloride/chlorine, and except low risk waste exempt from the trial burn requirements under §§ 266.104(a)(5), 266.105, 266.106, and 266.107) must not be fed into the device unless the device is operating within the conditions of operation specified in the permit.

(3) Requirements to ensure conformance with the particulate standard.

(i) Except as provided in paragraphs (e)(3)(ii) and (iii) of this section, the permit shall specify the following operating requirements to ensure conformance with the particulate standard specified in §266.105:

(A) Total ash feed rate to the device from hazardous waste, other fuels, and industrial furnace feedstocks, measured and specified as prescribed in paragraph (e)(6) of this section;

(B) Maximum device production rate when producing normal product expressed in appropriate units, and measured and specified as prescribed in paragraph (e)(6) of this section;

(C) Appropriate controls on operation and maintenance of the hazardous waste firing system and any air pollution control system;

(D) Allowable variation in boiler and industrial furnace system design including any air pollution control system or operating procedures; and

(E) Such other operating requirements as are necessary to ensure that the particulate standard in §266.105(a) is met.

(ii) Permit conditions to ensure conformance with the particulate matter standard shall not be provided for facilities exempt from the particulate matter standard under §266.105(b);

(iii) For cement kilns and light-weight aggregate kilns, permit conditions to ensure compliance with the particulate standard shall not limit the ash content of hazardous waste or other feed materials.

(4) Requirements to ensure conformance with the metals emissions standard.

(A) Total feed rate of each metal in hazardous waste, other fuels, and industrial furnace feedstocks measured and specified under provisions of paragraph (e)(6) of this section;

(B) Total feed rate of hazardous waste measured and specified as prescribed in paragraph (e)(6) of this section;

(C) A sampling and metals analysis program for the hazardous waste, other fuels, and industrial furnace feedstocks;

(A) Maximum emission rate for each metal specified as the average emission rate during the trial burn;

(B) Feed rate of total hazardous waste and pumpable hazardous waste, each measured and specified as prescribed in paragraph (e)(6)(i) of this section;

(C) Feed rate of each metal in the following feedstreams, measured and specified as prescribed in paragraphs (e)(6) of this section:

(2) Total hazardous waste feed; and

(3) Total pumpable hazardous waste feed;

(D) Total feed rate of chlorine and chloride in total feed streams measured and specified as prescribed in paragraph (e)(6) of this section;

(E) Maximum combustion gas temperature measured at a location indicative of combustion chamber temperature, and measured and specified as prescribed in paragraph (e)(6) of this section;

(F) Maximum flue gas temperature at the inlet to the particulate matter air pollution control system measured and specified as prescribed in paragraph (e)(6) of this section;

(G) Maximum device production rate when producing normal product expressed in appropriate units and measured and specified as prescribed in paragraph (e)(6) of this section;

(H) Appropriate controls on operation and maintenance of the hazardous waste firing system and any air pollution control system;

(I) Allowable variation in boiler and industrial furnace system design including any air pollution control system or operating procedures; and

(J) Such other operating requirements as are necessary to ensure that the metals standards under §§ 266.106(c) or 266.106(d) are met.

(A) Maximum emission rate for each metal specified as the average emission rate during the trial burn;

(B) Feed rate of total hazardous waste and pumpable hazardous waste, each measured and specified as prescribed in paragraph (e)(6)(i) of this section;

(C) Feed rate of each metal in the following feedstreams, measured and specified as prescribed in paragraph (e)(6) of this section:

(1) Total hazardous waste feed; and

(2) Total pumpable hazardous waste feed;

(D) Total feed rate of chlorine and chloride in total feed streams measured and specified prescribed in paragraph (e)(6) of this section;

(E) Maximum combustion gas temperature measured at a location indicative of combustion chamber temperature, and measured and specified as prescribed in paragraph (e)(6) of this section;

(F) Maximum flue gas temperature at the inlet to the particulate matter air pollution control system measured and specified as prescribed in paragraph (e)(6) of this section;

(G) Maximum device production rate when producing normal product expressed in appropriate units and measured and specified as prescribed in paragraph (e)(6) of this section;

(H) Appropriate controls on operation and maintenance of the hazardous waste firing system and any air pollution control system;

(I) Allowable variation in boiler and industrial furnace system design including any air pollution control system or operating procedures; and

(J) Such other operating requirements as are necessary to ensure that the metals standards under §§ 266.106(c) or 266.106(d) are met.

(5) Requirements to ensure conformance with the hydrogen chloride and chlorine gas standards.

(i) For conformance with the Tier I total chloride and chlorine feed rate screening limits of §266.107(b)(1), the permit will specify the following operating requirements:

(A) Feed rate of total chloride and chlorine in hazardous waste, other fuels, and industrial furnace feedstocks measured and specified as prescribed in paragraph (e)(6) of this section;

(B) Feed rate of total hazardous waste measured and specified as prescribed in paragraph (e)(6) of this section;

(C) A sampling and analysis program for total chloride and chlorine for the hazardous waste, other fuels, and industrial furnace feedstocks;

(ii) For conformance with the Tier II HCl and Cl2 emission rate screening limits under §266.107(b)(2) and the Tier III HCl and Cl2 controls under §266.107(c), the permit will specify the following operating requirements:

(A) Maximum emission rate for HCl and for Cl2 specified as the average emission rate during the trial burn;

(B) Feed rate of total hazardous waste measured and specified as prescribed in paragraph (e)(6) of this section;

(C) Total feed rate of chlorine and chloride in total feed streams, measured and specified as prescribed in paragraph (e)(6) of this section;

(D) Maximum device production rate when producing normal product expressed in appropriate units, measured and specified as prescribed in paragraph (e)(6) of this section;

(E) Appropriate controls on operation and maintenance of the hazardous waste firing system and any air pollution control system;

(F) Allowable variation in boiler and industrial furnace system design including any air pollution control system or operating procedures; and

(G) Such other operating requirements as are necessary to ensure that the HCl and Cl2 standards under §266.107 (b)(2) or (c) are met.

(6) Measuring parameters and establishing limits based on trial burn data-

(i) General requirements. As specified in paragraphs (e)(2) through (e)(5) of this section, each operating parameter shall be measured, and permit limits on the parameter shall be established, according to either of the following procedures:

(A) Instantaneous limits. A parameter may be measured and recorded on an instantaneous basis (i.e., the value that occurs at any time) and the permit limit specified as the time-weighted average during all valid runs of the trial burn; or

(B) Hourly rolling average.

(1) The limit for a parameter may be established and continuously monitored on an hourly rolling average basis defined as follows:

(i) A continuous monitor is one which continuously samples the regulated parameter without interruption, and evaluates the detector response at least once each 15 seconds, and computes and records the average value at least every 60 seconds.

(ii) An hourly rolling average is the arithmetic mean of the 60 most recent 1-minute average values recorded by the continuous monitoring system.

(2) The permit limit for the parameter shall be established based on trial burn data as the average over all valid test runs of the highest hourly rolling average value for each run.

(ii) Rolling average limits for carcinogenic metals and lead. Feed rate limits for the carcinogenic metals (i.e., arsenic, beryllium, cadmium and chromium) and lead may be established either on an hourly rolling average basis as prescribed by paragraph (e)(6)(i) of this section or on (up to) a 24 hour rolling average basis. If the owner or operator elects to use an average period from 2 to 24 hours:

(A) The feed rate of each metal shall be limited at any time to ten times the feed rate that would be allowed on an hourly rolling average basis;

(B) The continuous monitor shall meet the following specifications:

1) A continuous monitor is one which continuously samples the regulated parameter without interruption, and evaluates the detector response at least once each 15 seconds, and computes and records the average value at least every 60 seconds.

(2) The rolling average for the selected averaging period is defined as the arithmetic mean of one hour block averages for the averaging period. A one hour block average is the arithmetic mean of the one minute averages recorded during the 60-minute period beginning at one minute after the beginning of the preceding clock hour; and

(C) The permit limit for the feed rate of each metal shall be established based on trial burn data as the average over all valid test runs of the highest hourly rolling average feed rate for each run.

(iii) Feed rate limits for metals, total chloride and chlorine, and ash. Feed rate limits for metals, total chlorine and chloride, and ash are established and monitored by knowing the concentration of the substance (i.e., metals, chloride/chlorine, and ash) in each feedstream and the flow rate of the feedstream. To monitor the feed rate of these substances, the flow rate of each feedstream must be monitored under the continuous monitoring requirements of paragraphs (e)(6) (i) and (ii) of this section.

(iv) Conduct of trial burn testing.

(A) If compliance with all applicable emissions standards of §§ 266.104 through 266.107 is not demonstrated simultaneously during a set of test runs, the operating conditions of additional test runs required to demonstrate compliance with remaining emissions standards must be as close as possible to the original operating conditions.

(B) Prior to obtaining test data for purposes of demonstrating compliance with the emissions standards of §§ 266.104 through 266.107 or establishing limits on operating parameters under this section, the facility must operate under trial burn conditions for a sufficient period to reach steady-state operations. The Secretary may determine, however, that industrial furnaces that recycle collected particulate matter back into the furnace and that comply with an alternative implementation approach for metals under §266.106(f) need not reach steady state conditions with respect to the flow of metals in the system prior to beginning compliance testing for metals emissions.

(C) Trial burn data on the level of an operating parameter for which a limit must be established in the permit must be obtained during emissions sampling for the pollutant(s) (i.e., metals, PM, HCl/Cl2, organic compounds) for which the parameter must be established as specified by paragraph (e) of this section.

(7) General requirements-

(i) Fugitive emissions. Fugitive emissions must be controlled by:

(A) Keeping the combustion zone totally sealed against fugitive emissions; or

(B) Maintaining the combustion zone pressure lower than atmospheric pressure; or

(C) An alternate means of control demonstrated (with Part B of the permit application) to provide fugitive emissions control equivalent to maintenance of combustion zone pressure lower than atmospheric pressure.

(ii) Automatic waste feed cutoff. A boiler or industrial furnace must be operated with a functioning system that automatically cuts off the hazardous waste feed when operating conditions deviate from those established under this section. The Secretary may limit the number of cutoffs per an operating period on a case-by-case basis. In addition:

(A) The permit limit for (the indicator of) minimum combustion chamber temperature must be maintained while hazardous waste or hazardous waste residues remain in the combustion chamber,

(B) Exhaust gases must be ducted to the air pollution control system operated in accordance with the permit requirements while hazardous waste or hazardous waste residues remain in the combustion chamber; and

(C) Operating parameters for which permit limits are established must continue to be monitored during the cutoff, and the hazardous waste feed shall not be restarted until the levels of those parameters comply with the permit limits. For parameters that may be monitored on an instantaneous basis, the Secretary will establish a minimum period of time after a waste feed cutoff during which the parameter must not exceed the permit limit before the hazardous waste feed may be restarted.

(iii) Changes. A boiler or industrial furnace must cease burning hazardous waste when changes in combustion properties, or feed rates of the hazardous waste, other fuels, or industrial furnace feedstocks, or changes in the boiler or industrial furnace design or operating conditions deviate from the limits as specified in the permit.

(8) Monitoring and Inspections.

(i) The owner or operator must monitor and record the following, at a minimum, while burning hazardous waste:

(A) If specified by the permit, feed rates and composition of hazardous waste, other fuels, and industrial furnace feedstocks, and feed rates of ash, metals, and total chloride and chlorine;

(B) If specified by the permit, carbon monoxide (CO), hydrocarbons (HC), and oxygen on a continuous basis at a common point in the boiler or industrial furnace downstream of the combustion zone and prior to release of stack gases to the atmosphere in accordance with operating requirements specified in paragraph (e)(2)(ii) of this section. CO, HC, and oxygen monitors must be installed, operated, and maintained in accordance with methods specified in Appendix IX of this part.

(C) Upon the request of the Secretary, sampling and analysis of the hazardous waste (and other fuels and industrial furnace feedstocks as appropriate), residues, and exhaust emissions must be conducted to verify that the operating requirements established in the permit achieve the applicable standards of §§ 266.104, 266.105, 266.106, and 266.107.

(ii) All monitors shall record data in units corresponding to the permit limit unless otherwise specified in the permit.

(iii) The boiler or industrial furnace and associated equipment (pumps, valves, pipes, fuel storage tanks, etc.) must be subjected to thorough visual inspection when it contains hazardous waste, at least daily for leaks, spills, fugitive emissions, and signs of tampering.

(iv) The automatic hazardous waste feed cutoff system and associated alarms must be tested at least once every 7 days when hazardous waste is burned to verify operability, unless the applicant demonstrates to the Secretary that weekly inspections will unduly restrict or upset operations and that less frequent inspections will be adequate. At a minimum, operational testing must be conducted at least once every 30 days.

(v) These monitoring and inspection data must be recorded and the records must be placed in the operating record required by §264.73 of these regulations.

(9) Direct transfer to the burner. If hazardous waste is directly transferred from a transport vehicle to a boiler or industrial furnace without the use of a storage unit, the owner and operator must comply with §266.111.

(10) Recordkeeping. The owner or operator must keep in the operating record of the facility all information and data required by this section until closure of the facility.

(11) Closure. At closure, the owner or operator must remove all hazardous waste and hazardous waste residues (including, but not limited to, ash, scrubber waters, and scrubber sludges) from the boiler or industrial furnace.

22 DE Reg. 678 (02/01/19)

Section 266.103 Interim status standards for burners.

(i) The purpose of this section is to establish minimum national standards for owners and operators of "existing" boilers and industrial furnaces that burn hazardous waste where such standards define the acceptable management of hazardous waste during the period of interim status. The standards of this section apply to owners and operators of existing facilities until either a permit is issued under §266.102(d) or until closure responsibilities identified in this section are fulfilled.

(ii) "Existing or in existence" means a boiler or industrial furnace that on or before August 21, 1991 is either in operation burning or processing hazardous waste or for which construction (including the ancillary facilities to burn or to process the hazardous waste) has commenced. A facility has commenced construction if the owner or operator has obtained the Federal, State, and local approvals or permits necessary to begin physical construction; and either:

(A) A continuous on-site, physical construction program has begun; or

(B) The owner or operator has entered into contractual obligations-which cannot be canceled or modified without substantial loss-for physical construction of the facility to be completed within a reasonable time.

(iii) If a boiler or industrial furnace is located at a facility that already has a permit or interim status, then the facility must comply with the applicable regulations dealing with permit modifications in §122.42 or changes in interim status in §122.72 of these regulations.

(2) Exemptions. The requirements of this section do not apply to hazardous waste and facilities exempt under §§ 266.100(b), or 266.108.

(3) Prohibition on burning dioxin-listed wastes. The following hazardous waste listed for dioxin and hazardous waste derived from any of these wastes may not be burned in a boiler or industrial furnace operating under interim status: F020, F021, F022, F023, F026, and F027.

(4) Applicability of Part 265 standards. Owners and operators of boilers and industrial furnaces that burn hazardous waste and are operating under interim status are subject to the following provisions of Part 265 of these regulations, except as provided otherwise by this section:

(i) In Subpart A (General), §265.4;

(ii) In Subpart B (General facility standards), §§ 265.11-265.17;

(iii) In Subpart C (Preparedness and prevention), §§ 265.31-265.37;

(iv) In Subpart D (Contingency plan and emergency procedures), §§ 265.51-265.56;

(v) In Subpart E (Manifest system, recordkeeping, and reporting), §§ 265.71-265.77, except that §§ 265.71, 265.72, and 265.76 do not apply to owners and operators of on-site facilities that do not receive any hazardous waste from off-site sources;

(vi) In Subpart G (Closure and post-closure), §§ 265.111-265.115;

(vii) In Subpart H (Financial requirements), §§ 265.141, 265.142, 265.143, and 265.147-265.148, except that States and the Federal government are exempt from the requirements of Subpart H; and

(viii) Subpart BB (Air emission standards for equipment leaks), except §265.1050(a).

(5) Special requirements for furnaces. The following controls apply during interim status to industrial furnaces (e.g., kilns, cupolas) that feed hazardous waste for a purpose other than solely as an ingredient (see paragraph (a)(5)(ii) of this section) at any location other than the hot end where products are normally discharged or where fuels are normally fired:

(A) The hazardous waste shall be fed at a location where combustion gas temperatures are at least 1800oF;

(B) The owner or operator must determine that adequate oxygen is present in combustion gases to combust organic constituents in the waste and retain documentation of such determination in the facility record;

(C) For cement kiln systems, the hazardous waste shall be fed into the kiln; and

(D) The hydrocarbon controls of §266.104(c) or paragraph (c)(5) of this section apply upon certification of compliance under paragraph (c) of this section irrespective of the CO level achieved during the compliance test.

(ii) Burning hazardous waste solely as an ingredient. A hazardous waste is burned for a purpose other than solely as an ingredient if it meets either of these criteria:

(A The hazardous waste has a total concentration of nonmetal compounds listed in Part 261, Appendix VIII, of these regulations exceeding 500 ppm by weight, as-fired, and so is considered to be burned for destruction. The concentration of nonmetal compounds in a waste as-generated may be reduced to the 500 ppm limit by bona fide treatment that removes or destroys nonmetal constituents. Blending for dilution to meet the 500 ppm limit is prohibited and documentation that the waste has not been impermissibly diluted must be retained in the facility record; or

(B) The hazardous waste has a heating value of 5,000 Btu/lb or more, as-fired, and so is considered to be burned as fuel. The heating value of a waste as-generated may be reduced to below the 5,000 Btu/lb limit by bona fide treatment that removes or destroys organic constituents. Blending to augment the heating value to meet the 5,000 Btu/lb limit is prohibited and documentation that the waste has not been impermissibly blended must be retained in the facility record.

(6) Restrictions on burning hazardous waste that is not a fuel. Prior to certification of compliance under paragraph (c) of this section, owners and operators shall not feed hazardous waste that has a heating value less than 5,000 Btu/lb, as-generated, (except that the heating value of a waste as-generated may be increased to above the 5,000 Btu/lb limit by bona fide treatment; however, blending to augment the heating value to meet the 5,000 Btu/lb limit is prohibited and records must be kept to document that impermissible blending has not occurred) in a boiler or industrial furnace, except that:

(i) Hazardous waste may be burned solely as an ingredient; or

(ii) Hazardous waste may be burned for purposes of compliance testing (or testing prior to compliance testing) for a total period of time not to exceed 720 hours; or

(iii) Such waste may be burned if the Secretary has documentation to show that, prior to August 21, 1991:

(A) The boiler or industrial furnace is operating under the interim status standards for incinerators provided by Subpart O of Part 265 of these regulations, or the interim status standards for thermal treatment units provided by Subpart P of Part 265 of these regulations; and

(B) The boiler or industrial furnace met the interim status eligibility requirements under §122.70 of these regulations for Subpart O or Subpart P of Part 265 of these regulations; and

(C) Hazardous waste with a heating value less than 5,000 Btu/lb was burned prior to that date; or

(iv) Such waste may be burned in a halogen acid furnace if the waste was burned as an excluded ingredient under §261.2(e) of these regulations prior to February 21, 1991 and documentation is kept on file supporting this claim.

(7) Direct transfer to the burner. If hazardous waste is directly transferred from a transport vehicle to a boiler or industrial furnace without the use of a storage unit, the owner and operator must comply with §266.111.

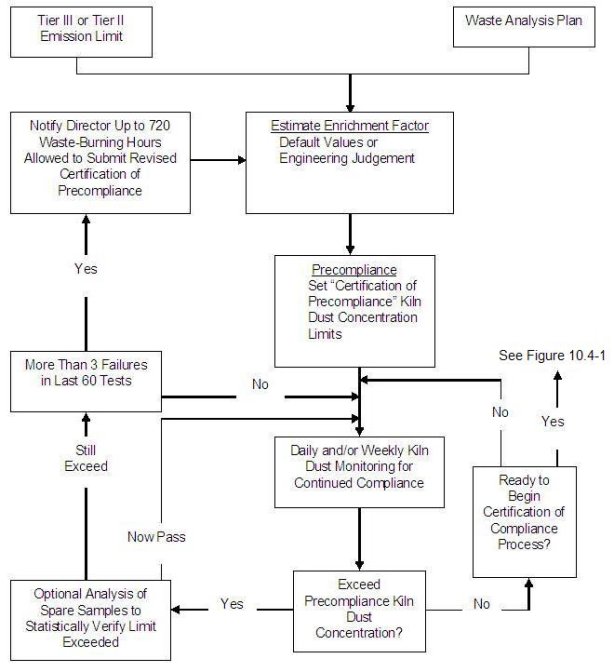

(1) General. The owner or operator must provide complete and accurate information specified in paragraph (b)(2) of this section to the Secretary on or before August 21, 1991, and must establish limits for the operating parameters specified in paragraph (b)(3) of this section. Such information is termed a "certification of precompliance" and constitutes a certification that the owner or operator has determined that, when the facility is operated within the limits specified in paragraph (b)(3) of this section, the owner or operator believes that, using best engineering judgment, emissions of particulate matter, metals, and HCl and Cl2 are not likely to exceed the limits provided by §§ 266.105, 266.106, and 266.107. The facility may burn hazardous waste only under the operating conditions that the owner or operator establishes under paragraph (b)(3) of this section until the owner or operator submits a revised certification of precompliance under paragraph (b)(8) of this section or a certification of compliance under paragraph (c) of this section, or until a permit is issued.

(2) Information required. The following information must be submitted with the certification of precompliance to support the determination that the limits established for the operating parameters identified in paragraph (b)(3) of this section are not likely to result in an exceedance of the allowable emission rates for particulate matter, metals, and HCl and Cl2:

(i) General facility information:

(A) EPA facility ID number;

(B) Facility name, contact person, telephone number, and address;

(C) Description of boilers and industrial furnaces burning hazardous waste, including type and capacity of device;

(D) A scaled plot plan showing the entire facility and location of the boilers and industrial furnaces burning hazardous waste; and

(E) A description of the air pollution control system on each device burning hazardous waste, including the temperature of the flue gas at the inlet to the particulate matter control system.

(ii) Except for facilities complying with the Tier I or Adjusted Tier I feed rate screening limits for metals or total chlorine and chloride provided by §§ 266.106 (b) or (e) and 266.107 (b)(1) or (e) respectively, the estimated uncontrolled (at the inlet to the air pollution control system) emissions of particulate matter, each metal controlled by §266.106, and hydrogen chloride and chlorine, and the following information to support such determinations:

(A) The feed rate (lb/hr) of ash, chlorine, antimony, arsenic, barium, beryllium, cadmium, chromium, lead, mercury, silver, and thallium in each feedstream (hazardous waste, other fuels, and industrial furnace feedstocks);

(B) The estimated partitioning factor to the combustion gas for the materials identified in paragraph (b)(2)(ii)(A) of this section and the basis for the estimate and an estimate of the partitioning to HCl and Cl2 of total chloride and chlorine in feed materials. To estimate the partitioning factor, the owner or operator must use either best engineering judgment or the procedures specified in Appendix IX of this part.

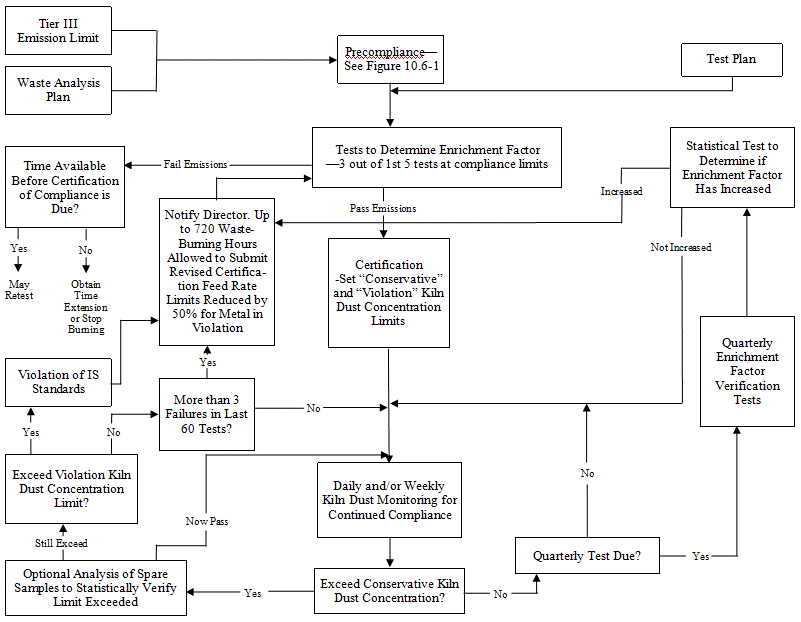

(C) For industrial furnaces that recycle collected particulate matter (PM) back into the furnace and that will certify compliance with the metals emissions standards under paragraph (c)(3)(ii)(A), the estimated enrichment factor for each metal. To estimate the enrichment factor, the owner or operator must use either best engineering judgment or the procedures specified in "Alternative Methodology for Implementing Metals Controls" in Appendix IX of this part.

(D) If best engineering judgment is used to estimate partitioning factors or enrichment factors under paragraphs (b)(2)(ii)(B) or (b)(2)(ii)(C) respectively, the basis for the judgment. When best engineering judgment is used to develop or evaluate data or information and make determinations under this section, the determinations must be made by a qualified, registered professional engineer and a certification of his/her determinations in accordance with §122.11(d) of these regulations must be provided in the certification of precompliance.

(iii) For facilities complying with the Tier I or Adjusted Tier I feed rate screening limits for metals or total chlorine and chloride provided by §§ 266.106 (b) or (e) and 266.107 (b)(1) or (e), the feed rate (lb/hr) of total chloride and chlorine, antimony, arsenic, barium, beryllium, cadmium, chromium, lead, mercury, silver, and thallium in each feedstream (hazardous waste, other fuels, industrial furnace feedstocks).

(iv) For facilities complying with the Tier II or Tier III emission limits for metals or HCl and Cl2 (under §§ 266.106 (c) or (d) or 266.107(b)(2) or (c)), the estimated controlled (outlet of the air pollution control system) emissions rates of particulate matter, each metal controlled by §266.106, and HCl and Cl2, and the following information to support such determinations:

(A) The estimated air pollution control system (APCS) removal efficiency for particulate matter, HCl, Cl2, antimony, arsenic, barium, beryllium, cadmium, chromium, lead, mercury, silver, and thallium.

(B) To estimate APCS removal efficiency, the owner or operator must use either best engineering judgment or the procedures prescribed in Appendix IX of this part.

(C) If best engineering judgment is used to estimate APCS removal efficiency, the basis for the judgment. Use of best engineering judgment must be in conformance with provisions of paragraph (b)(2)(ii)(D) of this section.

(v) Determination of allowable emissions rates for HCl, Cl2, antimony, arsenic, barium, beryllium, cadmium, chromium, lead, mercury, silver, and thallium, and the following information to support such determinations:

(1) Physical stack height;

(2) Good engineering practice stack height as defined by 40 CFR 51.100(ii);

(3) Maximum flue gas flow rate;

(4) Maximum flue gas temperature;

(5) Attach a US Geological Service topographic map (or equivalent) showing the facility location and surrounding land within 5 km of the facility;

(6) Identify terrain type: complex or noncomplex; and

(7) Identify land use: urban or rural.

(B) For owners and operators using Tier III site specific dispersion modeling to determine allowable levels under §266.106(d) or §266.107(c), or adjusted Tier I feed rate screening limits under §§ 266.106(e) or 266.107(e):

(1) Dispersion model and version used;

(2) Source of meteorological data;

(3) The dilution factor in micrograms per cubic meter per gram per second of emissions for the maximum annual average off-site (unless on-site is required) ground level concentration (MEI location); and

(4) Indicate the MEI location on the map required under paragraph (b)(2)(v)(A)(5);

(vi) For facilities complying with the Tier II or III emissions rate controls for metals or HCl and Cl2, a comparison of the estimated controlled emissions rates determined under paragraph (b)(2)(iv) with the allowable emission rates determined under paragraph (b)(2)(v);

(vii) For facilities complying with the Tier I (or adjusted Tier I) feed rate screening limits for metals or total chloride and chlorine, a comparison of actual feed rates of each metal and total chlorine and chloride determined under paragraph (b)(2)(iii) of this section to the Tier I allowable feed rates; and

(viii) For industrial furnaces that feed hazardous waste for any purpose other than solely as an ingredient (as defined by paragraph (a)(5)(ii) of this section) at any location other than the product discharge end of the device, documentation of compliance with the requirements of paragraphs (a)(5)(i) (A), (B), and (C) of this section.

(ix) For industrial furnaces that recycle collected particulate matter (PM) back into the furnace and that will certify compliance with the metals emissions standards under paragraph (c)(3)(ii) (A) of this section:

(A) The applicable particulate matter standard in lb/hr; and

(B) The precompliance limit on the concentration of each metal in collected PM.

(3) Limits on operating conditions. The owner and operator shall establish limits on the following arameters consistent with the determinations made under paragraph (b)(2) of this section and certify (under provisions of paragraph (b)(9) of this section) to the Secretary that the facility will operate within the limits during interim status when there is hazardous waste in the unit until revised certification of precompliance under paragraph (b)(8) of this section or certification of compliance under paragraph (c) of this section:

(i) Feed rate of total hazardous waste and (unless complying with the Tier I or adjusted Tier I metals feed rate screening limits under §266.106(b) or (e)) pumpable hazardous waste;

(ii) Feed rate of each metal in the following feed streams:

(A) Total feed streams, except that industrial furnaces that comply with the alternative metals implementation approach under paragraph (b)(4) of this section must specify limits on the concentration of each metal in collected particulate matter in lieu of feed rate limits for total feedstreams;

(B) Total hazardous waste feed, unless complying with the Tier I or Adjusted Tier I metals feed rate screening limits under §266.106(b) or (e); and

(C) Total pumpable hazardous waste feed, unless complying with the Tier I or adjusted Tier I metals feed rate screening limits under §266.106 (b) or (e);

(iii) Total feed rate of chlorine and chloride in total feed streams;

(iv) Total feed rate of ash in total feed streams, except that the ash feed rate for cement kilns and light-weight aggregate kilns is not limited; and

(v) Maximum production rate of the device in appropriate units when producing normal product, unless complying with the Tier I or Adjusted Tier I feed rate screening limits for chlorine under §266.107(b)(1) or (e) and for all metals under §266.106(b) or (e), and the uncontrolled particulate emissions do not exceed the standard under §266.105.

(4) Operating requirements for furnaces that recycle PM. Owners and operators of furnaces that recycle collected particulate matter (PM) back into the furnace and that will certify compliance with the metals emissions controls under paragraph (c)(3)(ii)(A) of this section must comply with the special operating requirements provided in "Alternative Methodology for Implementing Metals Controls" in Appendix IX of this part.

(5) Measurement of feed rates and production rate-

(i) General requirements. Limits on each of the parameters specified in paragraph (b)(3) of this section (except for limits on metals concentrations in collected particulate matter (PM) for industrial furnaces that recycle collected PM) shall be established and continuously monitored under either of the following methods:

(A) Instantaneous limits. A limit for a parameter may be established and continuously monitored and recorded on an instantaneous basis (i.e., the value that occurs at any time) not to be exceeded at any time; or

(B) Hourly rolling average limits. A limit for a parameter may be established and continuously monitored on an hourly rolling average basis defined as follows:

(1) A continuous monitor is one which continuously samples the regulated parameter without interruption, and evaluates the detector response at least once each 15 seconds, and computes and records the average value at least every 60 seconds.

(2) An hourly rolling average is the arithmetic mean of the 60 most recent 1-minute average values recorded by the continuous monitoring system.

(ii) Rolling average limits for carcinogenic metals and lead. Feed rate limits for the carcinogenic metals (arsenic, beryllium, cadmium, and chromium) and lead may be established either on an hourly rolling average basis as prescribed by paragraph (b)(5)(i)(B) or on (up to) a 24 hour rolling average basis. If the owner or operator elects to use an averaging period from 2 to 24 hours:

(A) The feed rate of each metal shall be limited at any time to ten times the feed rate that would be allowed on an hourly rolling average basis;

(B) The continuous monitor shall meet the following specifications:

(1) A continuous monitor is one which continuously samples the regulated parameter without interruption, and evaluates the detector response at least once each 15 seconds, and computes and records the average value at least every 60 seconds.

(2) The rolling average for the selected averaging period is defined as the arithmetic mean of one hour block averages for the averaging period. A one hour block average is the arithmetic mean of the one minute averages recorded during the 60-minute period beginning at one minute after the beginning of preceding clock hour.

(iii) Feed rate limits for metals, total chloride and chlorine, and ash. Feed rate limits for metals, total chlorine and chloride, and ash are established and monitored by knowing the concentration of the substance (i.e., metals, chloride/chlorine, and ash) in each feedstream and the flow rate of the feedstream. To monitor the feed rate of these substances, the flow rate of each feedstream must be monitored under the continuous monitoring requirements of paragraphs (b)(5) (i) and (ii) of this section.

(6) Public notice requirements at precompliance. On or before August 21, 1991, the owner or operator must submit a notice with the following information for publication in a major local newspaper of general circulation and send a copy of the notice to the appropriate units of State and local government. The owner and operator must provide to the Secretary with the certification of precompliance evidence of submitting the notice for publication. The notice, which shall be entitled "Notice of Certification of Precompliance with Hazardous Waste Burning Requirements of 40 CFR 266.103(b)", must include:

(i) Name and address of the owner and operator of the facility as well as the location of the device burning hazardous waste;

(ii) Date that the certification of precompliance is submitted to the Secretary;

(iii) Brief description of the regulatory process required to comply with the interim status requirements of this section including required emissions testing to demonstrate conformance with emissions standards for organic compounds, particulate matter, metals, and HCl and Cl2;

(iv) Types and quantities of hazardous waste burned including, but not limited to, source, whether solids or liquids, as well as an appropriate description of the waste;

(v) Type of device(s) in which the hazardous waste is burned including a physical description and maximum production rate of each device;

(vi) Types and quantities of other fuels and industrial furnace feedstocks fed to each unit;

(vii) Brief description of the basis for this certification of precompliance as specified in paragraph (b)(2) of this section;

(viii) Locations where the record for the facility can be viewed and copied by interested parties. These records and locations shall at a minimum include:

(A) The administrative record kept by DNREC where the supporting documentation was submitted or another location designated by the Secretary; and

(B) The BIF correspondence file kept at the facility site where the device is located. The correspondence file must include all correspondence between the facility and the Secretary, State and local regulatory officials, including copies of all certifications and notifications, such as the precompliance certification, precompliance public notice, notice of compliance testing, compliance test report, compliance certification, time extension requests and approvals or denials, enforcement notifications of violations, and copies of EPA and State site visit reports submitted to the owner or operator.

(ix) Notification of the establishment of a facility mailing list whereby interested parties shall notify the DNREC that they wish to be placed on the mailing list to receive future information and notices about this facility; and

(x) Location (mailing address) of the DNREC Office, Hazardous Waste Section, where further information can be obtained on regulation of hazardous waste burning.

(7) Monitoring other operating parameters. When the monitoring systems for the operating parameters listed in paragraphs (c)(1)(v through xiii) of this section are installed and operating in conformance with vendor specifications or (for CO, HC, and oxygen) specifications provided by Appendix IX of this part, as appropriate, the parameters shall be continuously monitored and records shall be maintained in the operating record.

(8) Revised certification of precompliance. The owner or operator may revise at any time the information and operating conditions documented under paragraphs (b)(2) and (b)(3) of this section in the certification of precompliance by submitting a revised certification of precompliance under procedures provided by those paragraphs.

(i) The public notice requirements of paragraph (b)(6) of this section do not apply to recertifications.

(ii) The owner and operator must operate the facility within the limits established for the operating parameters under paragraph (b)(3) of this section until a revised certification is submitted under this paragraph or a certification of compliance is submitted under paragraph (c) of this section.

(9) Certification of precompliance statement. The owner or operator must include the following signed statement with the certification of precompliance submitted to the Secretary:

(1) Limits on operating conditions. The owner or operator shall establish limits on the following parameters based on operations during the compliance test (under procedures prescribed in paragraph (c)(4)(iv) of this section) or as otherwise specified and include these limits with the certification of compliance. The boiler or industrial furnace must be operated in accordance with these operating limits and the applicable emissions standards of §§ 266.104(b) through (e), 266.105, 266.106, 266.107, and 266.103(a)(5)(i)(D) at all times when there is hazardous waste in the unit.

(i) Feed rate of total hazardous waste and (unless complying with the Tier I or Adjusted Tier I metals feed rate screening limits under §266.106 (b) or (e)), pumpable hazardous waste;

(ii) Feed rate of each metal in the following feedstreams:

(A) Total feedstreams, except that:

(1) Facilities that comply with Tier I or Adjusted Tier I metals feed rate screening limits may set their operating limits at the metals feed rate screening limits determined under §266.106(b) or (e); and

(2) Industrial furnaces that must comply with the alternative metals implementation approach under paragraph (c)(3)(ii) of this section must specify limits on the concentration of each metal in the collected particulate matter in lieu of feed rate limits for total feedstreams;

(B) Total hazardous waste feed (unless complying with the Tier I or Adjusted Tier I metals feed rate screening limits under §266.106(b) or (e)); and

(C) Total pumpable hazardous waste feed (unless complying with the Tier I or Adjusted Tier I metals feed rate screening limits under §266.106(b) or (e));

(iii) Total feed rate of chlorine and chloride in total feed streams, except that facilities that comply with Tier I or Adjusted Tier I feed rate screening limits may set their operating limits at the total chlorine and chloride feed rate screening limits determined under §266.107(b)(1) or (e);

(iv) Total feed rate of ash in total feed streams, except that the ash feed rate for cement kilns and light-weight aggregate kilns is not limited;

(v) Carbon monoxide concentration, and where required, hydrocarbon concentration in stack gas. When complying with the CO controls of §266.104(b), the CO limit is 100 ppmv, and when complying with the HC controls of §266.104(c), the HC limit is 20 ppmv. When complying with the CO controls of §266.104(c), the CO limit is established based on the compliance test;

(vi) Maximum production rate of the device in appropriate units when producing normal product, unless complying with the Tier I or Adjusted Tier I feed rate screening limits for chlorine under §266.107(b)(1) or (e) and for all metals under §266.106(b) or (e), and the uncontrolled particulate emissions do not exceed the standard under §266.105;

(vii) Maximum combustion chamber temperature where the temperature measurement is as close to the combustion zone as possible and is upstream of any quench water injection (unless complying with the Tier I or Adjusted Tier I metals feed rate screening limits under §266.106(b) or (e));

(viii) Maximum flue gas temperature entering a particulate matter control device (unless complying with Tier I or Adjusted Tier I metals feed rate screening limits under §266.106(b) or (e) and the total chlorine and chloride feed rate screening limits under §266.107(b) or (e));

(ix) For systems using wet scrubbers, including wet ionizing scrubbers (unless complying with the Tier I or Adjusted Tier I metals feed rate screening limits under §266.106(b) or (e) and the total chlorine and chloride feed rate screening limits under §266.107(b)(1) or (e)):

(A) Minimum liquid to flue gas ratio;

(B) Minimum scrubber blowdown from the system or maximum suspended solids content of scrubber water; and

(C) Minimum pH level of the scrubber water;

(x) For systems using venturi scrubbers, the minimum differential gas pressure across the venturi (unless complying with the Tier I or Adjusted Tier I metals feed rate screening limits under §266.106(b) or (e) and the total chlorine and chloride feed rate screening limits under §266.107(b)(1) or (e));

(xi) For systems using dry scrubbers (unless complying with the Tier I or Adjusted Tier I metals feed rate screening limits under §266.106(b) or (e) and the total chlorine and chloride feed rate screening limits under §266.107(b)(1) or (e)):

(A) Minimum caustic feed rate; and

(B) Maximum flue gas flow rate;

(xii) For systems using wet ionizing scrubbers or electrostatic precipitators (unless complying with the Tier I or Adjusted Tier I metals feed rate screening limits under §266.106(b) or (e) and the total chlorine and chloride feed rate screening limits under §266.107(b)(1) or (e)):

(A) Minimum electrical power in kilovolt amperes (kVA) to the precipitator plates; and

(B) Maximum flue gas flow rate;

(xiii) For systems using fabric filters (baghouses), the minimum pressure drop (unless complying with the Tier I or Adjusted Tier I metals feed rate screening limits under §266.106(b) or (e) and the total chlorine and chloride feed rate screening limits under §266.107(b)(1) or (e)).

(2) Prior notice of compliance testing. At least 30 days prior to the compliance testing required by paragraph (c)(3) of this section, the owner or operator shall notify the Secretary and submit the following information:

(i) General facility information including:

(A) EPA facility ID number;

(B) Facility name, contact person, telephone number, and address;

(C) Person responsible for conducting compliance test, including company name, address, and telephone number, and a statement of qualifications;

(D) Planned date of the compliance test;

(ii) Specific information on each device to be tested including:

(A) Description of boiler or industrial furnace;

(B) A scaled plot plan showing the entire facility and location of the boiler or industrial furnace;

(C) A description of the air pollution control system;

(D) Identification of the continuous emission monitors that are installed, including:

(1) Carbon monoxide monitor;

(3) Hydrocarbon monitor, specifying the minimum temperature of the system and, if the temperature is less than 150oC, an explanation of why a heated system is not used (see paragraph (c)(5) of this section) and a brief description of the sample gas conditioning system.

(E) Indication of whether the stack is shared with another device that will be in operation during the compliance test;

(F) Other information useful to an understanding of the system design or operation.

(iii) Information on the testing planned, including a complete copy of the test protocol and Quality Assurance/Quality Control (QA/QC) plan, and a summary description for each test providing the following information at a minimum:

(A) Purpose of the test (e.g., demonstrate compliance with emissions of particulate matter); and

(B) Planned operating conditions, including levels for each pertinent parameter specified in paragraph (c)(1) of this section.

(i) General. Compliance testing must be conducted under conditions for which the owner or operator has submitted a certification of precompliance under paragraph (b) of this section and under conditions established in the notification of compliance testing required by paragraph (c)(2) of this section. The owner or operator may seek approval on a case-by-case basis to use compliance data from one unit in lieu of testing a similar onsite unit. To support the request, the owner or operator must provide a comparison of the hazardous waste burned and other feedstreams, and the design, operation, and maintenance of both the tested unit and similar unit. The Secretary shall provide written approval to use compliance test data in lieu of testing a similar unit if he finds that the hazardous wastes, the devices, and the operating conditions are sufficiently similar, and the data from the other compliance test is adequate to meet the requirements of §266.103(c).

(ii) Special requirements for industrial furnaces that recycle collected PM. Owners and operators of industrial furnaces that recycle back into the furnace particulate matter (PM) from the air pollution control system must comply with one of the following procedures for testing to determine compliance with the metals standards of §266.106(c) or (d):

(A) The special testing requirements prescribed in "Alternative Method for Implementing Metals Controls" in Appendix IX of this part; or

(B) Stack emissions testing for a minimum of 6 hours each day while hazardous waste is burned during interim status. The testing must be conducted when burning normal hazardous waste for that day at normal feed rates for that day and when the air pollution control system is operated under normal conditions. During interim status, hazardous waste analysis for metals content must be sufficient for the owner or operator to determine if changes in metals content may affect the ability of the facility to meet the metals emissions standards established under §266.106(c) or (d). Under this option, operating limits (under paragraph (c)(1) of this section) must be established during compliance testing under paragraph (c)(3) of this section only on the following parameters:

(C) Conduct compliance testing to determine compliance with the metals standards to establish limits on the operating parameters of paragraph (c)(1) of this section only after the kiln system has been conditioned to enable it to reach equilibrium with respect to metals fed into the system and metals emissions. During conditioning, hazardous waste and raw materials having the same metals content as will be fed during the compliance test must be fed at the feed rates that will be fed during the compliance test.

(iii) Conduct of compliance testing.

(A) If compliance with all applicable emissions standards of §§ 266.104 through 266.107 is not demonstrated simultaneously during a set of test runs, the operating conditions of additional test runs required to demonstrate compliance with remaining emissions standards must be as close as possible to the original operating conditions.

(B) Prior to obtaining test data for purposes of demonstrating compliance with the applicable emissions standards of §§ 266.104 through 266.107 or establishing limits on operating parameters under this section, the facility must operate under compliance test conditions for a sufficient period to reach steady-state operations. Industrial furnaces that recycle collected particulate matter back into the furnace and that comply with paragraphs (c)(3)(ii)(A) or (B) of this section, however, need not reach steady state conditions with respect to the flow of metals in the system prior to beginning compliance testing for metals.

(C) Compliance test data on the level of an operating parameter for which a limit must be established in the certification of compliance must be obtained during emissions sampling for the pollutant(s) (i.e., metals, PM, HCl/Cl2, organic compounds) for which the parameter must be established as specified by paragraph (c)(1) of this section.

(4) Certification of compliance. Within 90 days of completing compliance testing, the owner or operator must certify to the Secretary compliance with the emissions standards of §§ 266.104(b), (c), and (e), 266.105, 266.106, 266.107, and paragraph (a)(5)(i)(D) of this section. The certification of compliance must include the following information:

(i) General facility and testing information including:

(A) EPA facility ID number;

(B) Facility name, contact person, telephone number, and address;

(C) Person responsible for conducting compliance testing, including company name, address, and telephone number, and a statement of qualifications;

(D) Date(s) of each compliance test;

(E) Description of boiler or industrial furnace tested;

(F) Person responsible for quality assurance/quality control (QA/QC), title, and telephone number, and statement that procedures prescribed in the QA/QC plan submitted under §266.103(c)(2)(iii) have been followed, or a description of any changes and an explanation of why changes were necessary.

(G) Description of any changes in the unit configuration prior to or during testing that would alter any of the information submitted in the prior notice of compliance testing under paragraph (c)(2) of this section, and an explanation of why the changes were necessary;

(H) Description of any changes in the planned test conditions prior to or during the testing that alter any of the information submitted in the prior notice of compliance testing under paragraph (c)(2) of this section, and an explanation of why the changes were necessary; and