department of natural resources and environmental control

Division of Air and Waste Management

PROPOSED

PUBLIC NOTICE

1124 Control of Volatile Organic Compound Emissions

1. Title of the Regulations:

Revisions of 7 DE Admin. Code 1124 Sections 8.0, 13.0, 16.0, 23.0, 37.0, 45.0 and 47.0, and submittal of the revisions to the US Environmental Protection Agency (EPA) as revisions to Delaware State Implementation Plan (SIP).

2. Brief Synopsis of the Subject, Substance and Issues:

The Clean Air Act (CAA) Section 182(b)(2) requires that all ozone non-attainment areas, including Delaware, must develop or update relevant regulations to implement Reasonably Available Control Technology (RACT) controls on emission sources covered in EPA's Control Techniques Guidelines (CTG) or Alternate Control Techniques (ACT), and submit the regulations to EPA as State Implementation Plan (SIP) revisions. Recently, the EPA has updated several CTGs and the afore-mentioned revisions to 7 DE Admin. Code 1124 reflect DE's efforts accordingly. Specifically,

3. Possible Terms Of The Agency Action:

None

4. Statutory Basis or Legal Authority to Act:

7 Del.C., Chapter 60, Environmental Control

5. Other Regulations That May Be Affected By The Proposal:

None

6. Notice of Public Comment:

A public hearing will be held on June 2, 2010, beginning at 6:00 pm, in DNREC's Auditorium, R & R Building, 89 Kings Hwy, Dover, Delaware 19901.

7. Prepared By:

Frank F. Gao Phone: (302) 323-4542 Date: March 31, 2010 E-Mail: Frank.Gao@state.de.us

1124 Control of Volatile Organic Compound Emissions

*Please Note: Due to the size of the proposed regulation, it is not being published here. A copy of the regulation is available at:

http://regulations.delaware.gov/register/may2010/proposed/13 DE Reg XXX 05-01-10.htm

(Break in Continuity of Sections)

11/29/1994 mm/dd/2010

8.1 Except as provided for in 8.3, the requirements of 8.0 of this regulation apply to: any facility that is subject to any of the requirements of 10.0 through 50.0 of this regulation, and any facility that emits at least 6.8 kg/day (15 lb/day) of VOC before consideration of controls.

8.2 Definitions

"Cleanup solvent" means a VOC-containing material used to remove any loosely held uncured (i.e., not dry to the touch) adhesive or sealant that is subject to 4.0 of 7 DE Admin. Code 1141 from a substrate, or to clean equipment used in applying an adhesive or sealant subject to 4.0 of 7 DE Admin. Code 1141.

"Electrical and electronic components" means components and assemblies of components that generate, convert, transmit, or modify electrical energy. Electrical and electronic components include, but are not limited to, wires, windings, stators, rotors, magnets, contacts, relays, printed circuit boards, printed wire assemblies, wiring boards, integrated circuits, resistors, capacitors and transistors. Cabinets in which electrical and electronic components are housed are not considered electrical and electronic components.

"Flushing" means pumping a solvent from a reservoir through a pipe or hose or through equipment (e.g., pipes, hoses, tanks) to remove contaminants or residue.

"Hand-wiping" means a method of cleaning a surface by physically rubbing it with a material such as a rag, paper, sponge or a cotton swab moistened with a solvent.

"Medical device" means an instrument, apparatus, implement, machine, contrivance, implant, in vitro reagent or other similar article, including any component or accessory that is, (i) intended for use in the diagnosis of disease or other conditions, or in the cure, mitigation, treatment, or prevention of diseases, or (ii) is intended to affect the structure or any function of the body, or (iii) is defined in the National Formulary or the United States Pharmacopoeia or any supplement to it.

"Non-manufacturing area cleaning" means the cleaning of cafeterias, laboratories, pilot facilities, restrooms, office buildings, etc.

"Medical Device and Pharmaceutical Manufacturing" means Medical devices; pharmaceutical products; and associated manufacturing and product handling equipment and material, work surfaces, maintenance tools and room surfaces that are subject to US FDA current Good Manufacturing/Laboratory Practice, or CDC/NIH guidelines for biological disinfection of surfaces.

“Pharmaceutical product” means a preparation or compound, which includes any drug, analgesic, decongestant, antihistamine, cough suppressant, vitamin, mineral or herb supplement intended for human or animal consumption and used to cure, mitigate or treat disease or improve or enhance health.

"Precision optics" means the optical elements used in electro-optical devices that are designed to sense, detect, or transmit light energy, including specific wavelengths of light energy and changes of light energy levels.

"Solvent Cleaning Operation" means the removal of uncured adhesives, inks, coatings, or contaminants including dirt, soil, and grease from parts, products, tools, machinery, equipment, and general work areas. Solvent cleaning operations include hand-wiping, surface preparation, flushing and the cleaning of spray guns/cleaning of equipment used to spray coatings, adhesives, etc.

"Stripping" means the removal of cured coatings, cured inks, or cured adhesives.

"Surface preparation" means the removal of contaminants such as dust, soil, oil, grease, etc., prior to coating, adhesive, or ink applications.

"Surface preparation solvent" means a solvent used to remove dirt, oil and other contaminants from a substrate prior to the application of a primer, adhesive or sealant that is subject to 4.0 of 7 DE Admin. Code 1141.

8.3 Exemptions.

8.3.1 The requirements of 8.0 this regulation do not apply to any equipment or operation that is specifically subject to the emission limitations of 10.0, 11.0 or 38.0 of this regulation; or to any piece of equipment that is specifically subject to the requirements of 33.0 of this regulation.

8.3.2 Existing sources affected by 8.0 of this regulation shall comply with the provisions of 8.0 of this regulation on and after (insert the effective date), except for the requirements of 8.5 of this regulation. Existing sources affected by 8.5 of this regulation shall comply with the requirements of 8.5 of this regulation beginning as soon as practical, but no later than (insert one year after the effective date). New, modified, or reconstructed sources affected by 8.0 of this regulation shall comply with the provisions of 8.0 of this regulation on and after startup.

8.3.3 The requirements of 8.5 of this regulation shall not apply to any facility subject to 47.0 of this regulation, or to:

8.3.3.1 The surface preparation or cleaning of electrical and electronic components;

8.3.3.2 The surface preparation or cleaning of precision optics;

8.3.3.3 The surface preparation or cleaning of numismatic dies;

8.3.3.4 Stripping of cured inks, coatings, and adhesives;

8.3.3.5 The cleaning of resin, coating, ink, and adhesive mixing, molding, and application equipment;

8.3.3.6 Surface preparation associated with research and development activities;

8.3.3.7 Surface preparation associated with medical device and pharmaceutical manufacturing;

8.3.3.8 Cleaning associated with performance or quality assurance testing of coatings, inks, or adhesives involved;

8.3.3.9 Non-manufacturing area cleaning, and

8.3.3.10 The use of any surface preparation solvent or cleanup solvent subject to 4.0 of 7 DE Admin. Code 1141.

8.4 Work Practice Standards.

8.14.1 No owner or operator of a facility subject to 8.4 of this regulation may cause, allow, or permit the disposal of more than five kilograms (kg) (11 pounds [lb]) of any VOC, or of any materials containing more than five kg (11 lb) of any VOCs, at that facility in any one day in a manner that would permit the evaporation of VOC into the ambient air. This provision does not apply to:

8.14.1.1 Any VOC or material containing VOC emitted from a regulated entity that is subject to a VOC standard under this regulation.

8.14.1.2 Coating sources that are exempt from the emission limitations of 10.0 through 23.0 of this regulation.

8.14.1.3 Waste paint (sludge) handling systems, water treatment systems, and other similar operations at coating facilities using complying coatings.

8.14.1.4 Any VOC or material containing VOCs used during process maintenance turnarounds for cleaning purposes, provided that the provisions of 8.4.3, 8.4.4, and 8.4.5 and 8.4.6 of this regulation are followed.

8.14.2 The requirements of 8.14.1 of this regulation includes, but is not limited to, the disposal of VOC from VOC control devices.

8.14.3 No owner or operator of a facility subject to 8.4 of this regulation shall use open containers for the storage or disposal of cloth or paper impregnated with VOCs that are used for surface preparation, cleanup, or coating removal. Containers for the storage or disposal of cloth or paper impregnated with VOCs shall be kept closed, except when adding or removing material.

8.14.4 No owner or operator of a facility subject to 8.4 of this regulation shall store in open containers spent or fresh VOC to be used for surface preparation, cleanup or coating removal or VOC containing material. Containers for the storage of spent or fresh VOCs or VOC containing material shall be kept closed, except when adding or removing material.

8.14.5 No owner or operator of a facility subject to 8.4 of this regulation shall use VOC for the cleanup of spray equipment unless equipment is one or more of the following methods are used to collect the cleaning compounds and to minimize their evaporation to the atmosphere.

8.4.5.1 Use of an enclosed spray gun cleaning system that is kept closed when not in use.

8.4.5.2 Non-atomized discharge of solvent into a waste container that is kept closed when not in use.

8.4.5.3 Disassembly of the spray gun and cleaning in a vat that is kept closed when not in use.

8.4.5.4 Atomized spray into a waste container that is fitted with a device that captures atomized solvent emissions.

8.4.5.5 Any alternative technique that has been demonstrated to, and accepted by the Department as producing emissions that are equal to or less than the emissions from the techniques specified in 8.4.5.1 through 8.4.5.4 of this regulation. Emissions from any alternative technique shall be demonstrated pursuant to test protocols that are approved in advance by the Department.

8.4.6 Any owner or operator of a facility subject to 8.4 of this regulation shall:

8.4.6.1 Convey VOC-containing cleaning materials from one location to another in closed containers or pipes.

8.4.6.2 Handle and transfer all fresh and spent cleaning solvent and other VOC-containing material to or from any container, tank, vat, vessel, mixing vessel, or piping system, etc. in such a manner that minimizes spills and other losses.

8.4.6.3 Clean up spills of fresh and spent cleaning solvent and other VOC-containing material immediately.

8.4.7 Any owner or operator of a facility subject to 8.4 of this regulation shall minimize air circulation around cleaning operations and shall implement equipment practices that minimize emissions including keeping part cleaners covered when not in use, and maintaining cleaning equipment to repair solvent leaks.

8.5 Control Requirements. No owner or operator of a facility subject to 8.5 of this regulation shall use any liquid VOC containing material for any solvent cleaning operation that does not meet one of the requirements of 8.5.1 through 8.5.3.

8.5.1 The VOC content is equal to or less than 50 grams VOC per liter (0.42 1b/gal), as applied, or

8.5.2 The VOC composite vapor pressure is equal to or less than 8 millimeters of mercury (mmHg) at 20 degrees Celsius, as applied, or

8.5.3 The emissions of that material are controlled by an emission control system that:

8.5.3.1 Achieves an overall control efficiency of equal to or greater than 85 percent, by weight, or

8.5.3.2 Maintains a maximum outlet total organic carbon concentration of 20 parts per million by volume (ppmv) as carbon (C1) on a dry basis.

8.6 Test Methods and Procedures.

8.6.1 Any owner or operator subject to 8.5.1 of this regulation shall determine the VOC content of each cleaning solution using the test methods and procedures specified in Appendix A and Appendix B of this regulation, or using the manufacturer's product formulation data, and the following equation:

VOC Content (in grams per liter of material) = (WS -WW -Wes)/Vm

(8-1)

Where:

WS = Weight of volatile compounds in grams(g);

WW = Weight of water, in g;

Wes = Weight of exempt compounds in g;

Vm = Volume of material in liters

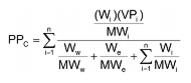

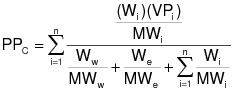

8.6.2 Any owner or operator subject to 8.5.2 of this regulation shall determine the VOC composite vapor pressure of each cleaning solution using the test methods and procedures specified in Appendix A and Appendix B of this regulation, or using the manufacturer's product formulation data, and the following equation:

(8-2)

Where:

Wi = Weight of the ith VOC compound, in grams (g);

Ww = Weight of water, in g;

We = Weight of exempt compound, in g;

MWi = Molecular weight of the ith VOC compound, in grams per gram-mole

MWw = Molecular weight of water, in grams per gram-mole

MWe = Molecular weight of exempt compound, in grams per gram-mole;

PPC = VOC composite partial pressure at 20°C, in mmHg

VPi = Vapor pressure of the ith VOC compound at 20°C, in mmHg

8.6.3 Any owner or operator subject to 8.5.3 of this regulation shall conduct an initial test to demonstrate the efficiency of each emission control system using the applicable test methods and procedures specified in Appendix A through Appendix E of this regulation. The cleaning operation shall operate at maximum operating conditions and flow rates during any emission testing.

8.7 Recordkeeping. Any owner or operator subject to 8.5 of this regulation shall maintain all of the information necessary for the Department to determine compliance with the applicable requirements of Section 8.5 of this regulation. Such information shall be made available to the Department upon verbal or written request, and shall be maintained for a minimum of five years from the date such record is created. Information sufficient to determine compliance shall include, but is not limited to the following:

8.7.1 Name and quantity of each cleaning solvent used,

8.7.2 VOC content or vapor pressure of each cleaning solvent, as applied,

8.7.3 Material Safety Data Sheets for all cleaning solvents used,

8.7.4 Documentation of air pollution control equipment efficiency or capture efficiency, if applicable,

8.7.5 Date and type of maintenance performed on air pollution control or capture equipment, if applicable, and

8.7.6 Quantity of non-compliant solvent used, in gallons, for each day, each week, and calendar year.

(Break in Continuity of Sections)

01/11/1993 mm/dd/2010

13.1 Applicability

13.1.1 The provisions of 13.0 of this regulation apply to the following coating operations in an automobile or light-duty truck assembly plant: each prime coat operation, each electro-deposition (EDP) prime coat operation, each primer surfacer operation, each topcoat operation, and each combined primer surfacer and topcoat operation, each final repair operation and each miscellaneous motor vehicle materials operation.

13.1.2 The requirements in 13.3.41 and 13.6 and 13.9 of this regulation also apply to heavy-duty trucks that use EDP to apply prime coat.

13.1.3 Anti-chip coatings, as applied to automobile and light-duty truck components such as, but not limited to, rocker panels, the bottom edge of doors and fenders, and the leading edge of the hood or roof, are considered primer surfacers.

13.1.4 Application to metal parts of underbody anti-chip coatings (e.g., underbody plastisol) and coatings other than prime, primer-surfacer, topcoat, and final repair and miscellaneous motor vehicle materials shall be subject to the requirements of 22.0 of this regulation (Miscellaneous Metal Parts).

13.1.5 The requirements in 13.3 of this regulation do not apply to automobile and light-duty truck assembly plants whose plant-wide, actual emissions without control devices are less than 6.8 kilograms (kg) (15 pounds [lb]) of volatile organic compounds (VOCs) per day.

13.1.6 An owner or operator of a facility whose emissions are below the applicability threshold in 13.1.5 of this regulation shall comply with the certification, recordkeeping, and reporting requirements in 4.2 of this regulation.

13.1.7 Any facility that becomes or is currently subject to all of the provisions of 13.0 of this regulation by exceeding the applicability threshold in 13.1.5 of this regulation will remain subject to these provisions even if its emissions later fall below the applicability threshold.

13.1.8 Any facility that is currently subject to a state or federal rule promulgated pursuant to the Clean Air Act Amendments of 1977 by exceeding an applicability threshold is and will remain subject to these provisions, even if its throughput or emissions later fall below the applicability threshold.

13.1.9 Transition period for existing permitted sources. Every owner or operator of any automobile or light-duty truck assembly plant that has a permit issued pursuant to 7 DE Admin. Code 1102 or 1130 containing all applicable conditions of 13.0 of this regulation, as that regulation existed on January 11, 1993, shall comply with those permit conditions until December 31, 2010. On and after January 1, 2011, every such owner or operator shall comply with the provisions of 13.0 of this regulation.

13.2 Definitions. As used in 13.0 of this regulation, all terms not defined herein shall have the meaning given them in this regulation or in the Clean Air Act Amendments (CAAA) of November 15, 1990, or in 2.0 of this regulation.

"Adhesive" means any chemical substance that is applied for the purpose of bonding two surfaces together other than by mechanical means.

“Application area” means the area where a coating is applied by dipping or spraying.

“Automobile” means a motor vehicle capable of carrying no more than 12 passengers.

"Automobile and light-duty truck adhesive" means an adhesive, including glass bonding adhesive, used at an automobile or light-duty truck assembly coating facility, applied for the purpose of bonding two vehicle surfaces together without regard to the substrates involved.

"Automobile and light-duty truck bedliner" means a multi-component coating, used at an automobile or light-duty truck assembly coating facility, applied to a cargo bed after the application of topcoat and outside of the topcoat operation to provide additional durability and chip resistance.

“Automobile and light-duty truck body” means the exterior and interior surfaces of an automobile or light-duty truck including, but not limited to, hoods, fenders, cargo boxes, doors, grill opening panels, engine compartment, all or portions of the passenger compartment, and trunk interior.

"Automobile and light-duty truck cavity wax" means a coating, used at an automobile or light-duty truck assembly coating facility, applied into the cavities of the vehicle primarily for the purpose of enhancing corrosion protection.

"Automobile and light-duty truck deadener" means a coating, used at an automobile or light-duty truck assembly coating facility, applied to selected vehicle surfaces primarily for the purpose of reducing the sound of road noise in the passenger compartment.

"Automobile and light-duty truck gasket/gasket sealing material" means a fluid, used at an automobile or light-duty truck assembly coating facility, applied to coat a gasket or replace and perform the same function as a gasket. Automobile and light-duty truck gasket/gasket sealing material includes room temperature vulcanization (RTV) seal material.

"Automobile and light-duty truck glass bonding primer" means a primer, used at an automobile or light-duty truck assembly coating facility, applied to windshield or other glass, or to body openings, to prepare the glass or body opening for the application of glass bonding adhesives or the installation of adhesive bonded glass. Automobile and light-duty truck glass bonding primer includes glass bonding/cleaning primers that perform both functions (cleaning and priming of the windshield and other glass, or body openings) prior to the application of adhesive or the installation of adhesive bonded glass.

"Automobile and light-duty truck lubricating wax/compound" means a protective lubricating material, used at an automobile or light-duty truck assembly coating facility, applied to vehicle hubs and hinges.

"Automobile and light-duty truck sealer" means a high viscosity material, used at an automobile or light-duty truck assembly coating facility, generally, but not always, applied in the paint shop after the body has received an electrodeposition primer coating and before the application of subsequent coatings (e.g. primer-surfacer). The primary purpose of the automobile and light-duty truck sealer is to fill body joints completely so that there is no intrusion of water, gases or corrosive materials into the passenger area of the compartment. Such materials are also referred to as sealant or caulk.

"Automobile and light-duty truck trunk interior coating" means a coating, used at an automobile or light-duty truck assembly coating facility outside of the primer-surfacer and topcoat operations, applied to the trunk interior to provide chip protection.

"Automobile and light-duty truck underbody coating" means a coating, used at an automobile or light-duty truck assembly coating facility, applied to the undercarriage or firewall to prevent corrosion and/or provide chip protection.

"Automobile and light-duty truck weatherstrip adhesive" means an adhesive, used at an automobile or light-duty truck assembly coating facility, applied to weatherstripping materials for the purpose of bonding the weatherstrip material to the surface of the vehicle.

“Electro-deposition (EDP)” means a method process of applying a protective, corrosion resistant waterborne prime coat by which the automobile or truck body is submerged in a tank filled with coating material and an electrical field is used to effect the deposition of the coating material on the body. Also referred to as E-Coat, Uni-Prime, and ELPO Primer.

“EDP prime coat operation” means the application area or areas, flashoff area or areas, and oven or ovens that are used to apply and dry or cure the EDP prime coat on components of automobile and truck bodies on a single assembly line.

“Final repair operation” means the application area or areas, flashoff area or areas, and oven or ovens used to apply and dry or cure coatings that are used to repair topcoat on fully assembled automobiles or light-duty truck bodies from a single assembly line. operations performed and coating applied to completely assembled motor vehicles or to parts that are not yet on a completely assembled vehicle to correct damage or imperfections in the coating. The curing of the coatings applied in these operations is accomplished at a lower temperature than used for curing primer-surfacer and topcoat. This lower temperature cure avoids the need to send parts that are not yet on a completely assembled vehicle through the same type of curing process used for primer-surfacer and topcoat and is necessary to protect heat sensitive components on completely assembled vehicles.

"In-line Repair" means the operation performed and coating used to correct damage or imperfections in the topcoat on parts that are on a completely assembled vehicle. The curing of the coatings applied in these operations is accomplished at essentially the same temperature as that used for curing the previously applied topcoat. Also referred to as high bake repair or high bake reprocess. In-line repair is considered part of the topcoat operation.

“Light-duty truck” means any motor vehicle rated at 3,864 kg (8,500 lb) gross weight or less designed primarily to transport property.

“Prime coat operation” means the application area or areas, flashoff area or areas, and oven or ovens that are used to apply and dry or cure the prime coat on components of automobile and light-duty truck bodies on a single assembly line.

“Primer-surfacer operation” means the application area or areas, flashoff area or areas, and oven or ovens that are used to apply and dry or cure primer surfacer between the prime coat and the topcoat operations on components of automobile and light-duty truck bodies on a single assembly line. The primer surfacer coat is also referred to as the "guidecoat."

"Primer-surfacer" means an intermediate protective coating applied over the electrodeposition primer and under the topcoat. Primer-surfacer provides adhesion, protection and appearance properties to the total finish. Primer-surfacer may also be called guide coat or surfacer. Primer-surfacer operations may include other coatings (e.g., anti-chip, lower-body anti-chip, chip resistant edge primer, spot primer, blackout, deadener, interior color, basecoat replacement coating, etc) that are applied in the same spray booth.

"Primer-surfacer and topcoat protocol" means the EPA document "Protocol for Determining the Daily Volatile Organic Compound Emission Rate of Automobile and Light-Duty Truck Primer-Surfacer and Topcoat Operations", EPA 453/R-08-002, September 2008.

“Solids turnover ratio (RT) (RT)” means the ratio of total volume of coating solids that is added to the EDP system in a calendar month divided by the total volume design capacity of the EDP system.

“Topcoat” means the final coating or coatings on components of automobile and light-duty truck bodies applied to provide the final color and/or a protective finish. The topcoat may be a monocoat color or basecoat/clearcoat system. In-line repair and two-tone are part of topcoat. Topcoat operations may include other coatings (e.g., blackout, interior color, etc.) that are applied in the same spray booth.

“Topcoat operation” means the application area or areas, flashoff area or areas, and oven or ovens used to apply and dry or cure topcoat on components of automobile and light-duty truck bodies on a single assembly line.

“Topcoat protocol” means the EPA document "Protocol for Determining the Daily VOC Emission Rate of Automobile and Light-Duty Truck Topcoat Operations," EPA 450/3-88-018, December 1988.

“Volume design capacity” means for the EDP system the total liquid volume that is contained in the EDP system (tanks, pumps, recirculating lines, filters, etc.) at the system's designed liquid operating level. The EDP system volume design capacity is designated LE LE.

13.3 Standards

13.3.41 No owner or operator of an EDP prime coat operation subject to 13.0 of this regulation shall cause or allow on any day the application of any coating on that operation with VOC content, as applied, that exceeds either of the following:

13.3.41.1 0.17 kg/L (1.4 lb/gal) 0.084 kg/l (0.7 lb/gal) of coating solids from any EDP prime coat operation when the solids turnover ratio (RT) is 0.16 or greater. RT shall be calculated as follows:

where:

TV =Total volume of coating solids that is added to the EDP system in a calendar month (liters).

LE = Volume design capacity of the EDP system (liters).

13.3.41.2 0.17 x 350 (0.160 - RT) 0.084 x 350 (0.160-RT) kg VOC/Ll of applied coating solids from any EDP prime coat operation when RT, calculated according to the equation in 13.3.4.1 13.1 of this regulation, is greater than or equal to 0.040 and less than 0.160.

13.3.41.3 When RT, calculated according to the equation in 13.3.4.1 13.1 of this regulation, is less than 0.040 for any EDP prime coat operation, there is no emission limit.

13.3.32 No owner or operator of an automobile or light-duty truck primer surface operation subject to 13.0 of this regulation shall cause or allow on any day VOC emissions which do not comply with one of the following: 1.44 kg VOC/liter of deposited solids (12.0 lb VOC/gal deposited solids) on a daily weighted average basis as determined by 13.6.2.

13.3.3.1 1.8 kg/L (15.1 lb/gal) of solids deposited.

13.3.3.2 0.34 kg/L (2.8 lb/gal) of coating, excluding water and exempt compounds, as applied.

13.3.23 No owner or operator of an automobile or light-duty truck topcoating operation subject to 13.0 of this regulation shall cause or allow on any day VOC emissions that do not comply with one of the following: 1.44 kg VOC/liter of deposited solids (12.0 lb VOC/gal deposited solids) on a daily weighted average basis as determined by 13.6.2.

13.3.2.1 1.8 kg/L (15.1 lb/gal) of solids deposited.

13.3.2.2 0.34 kg/L (2.8 lb/gal) of coating, excluding water and exempt compounds, as applied.

13.3.14 No owner or operator of an automobile or light-duty truck prime coat operation or final repair operation subject to 13.0 of this regulation shall cause or allow on any day the application of any coating on that operation with VOC content, as applied, that does not comply with one of the following: emission limits

13.3.14.1 0.14 kilograms per liter (kg/Ll) (1.2 pounds per gallon [lb/gal]) of coating, excluding water and exempt compounds, as applied, from any prime coat operation.

13.3.14.2 0.58 kg/Ll) (4.8 lb/gal) of coating, excluding water and exempt compounds, as applied, from any final repair operation.

13.3.14.3 4.10 kg/Ll) (34.2 lb/gal) of solids deposited from any final repair operation.

13.3.5 No owner or operator of an automobile or light-duty truck combined primer-surfacer and topcoat operation subject to 13.0 of this regulation shall cause of allow VOC emissions that do not comply with 1.44 kg VOC/liter of deposited solids (12.0 lb VOC/gal deposited solids) on a daily weighted average basis as determined by 13.6.2.

13.3.6 Additional VOC content limits for miscellaneous motor vehicle materials used at automotive and light-duty truck assembly facilities (grams of VOC per liter of coating excluding water and exempt compounds, as applied).

Table 13-1

13.3.7 The VOC emission limits in 13.3 of this regulation do not apply to materials supplied in containers with a net volume of 16 ounces or less or a net weight of one pound or less.

13.3.58 As an alternative to compliance with the emission limits in 13.3.1.1, 13.3.1.2, 13.3.2.2 and 13.3.3.2 of this regulation, an owner or operator may meet the requirements of 13.4 or 13.5 of this regulation.

13.4 Daily-weighted average limitation. No owner or operator subject to 13.0 of this regulation shall apply, during any day, coatings in any non-electro-deposition (non-EDP) prime coat, final repair, topcoat, or primer surfacer or miscellaneous motor vehicle materials operation whose daily-weighted average VOC content, calculated in accordance with the procedure specified in Appendix C of this regulation, exceeds the applicable emission limits in 13.3.14, 13.3.2.2 and 13.3.3.26 of this regulation.

13.5 Control devices

13.5.1 An owner or operator subject to 13.0 of this regulation shall may comply with the applicable emission limits for any non-EDP prime coat, final repair, topcoat, or primer surfacer coating operation by:

13.5.1.1 Installing and operating a capture system on that operation.

13.5.1.2 Installing and operating a control device on that operation.

13.5.1.3 Determining for each day the overall emission reduction efficiency needed to demonstrate compliance. The overall emission reduction needed for a day is the lesser of the value calculated according to the procedure in 3.0 3.1 and 3.2 of Appendix C of this regulation for that day or 95%.

13.5.1.4 Demonstrating each day that the overall emission reduction efficiency achieved for that day, as determined in 3.0 of Appendix D of this regulation, is greater than or equal to the overall emission reduction efficiency required for that day.

13.5.2 An owner or operator subject to 13.0 of this regulation shall ensure that:

13.5.2.1 A capture system and control device are operated at all times the coating operation is in use, and the owner or operator demonstrates compliance with 13.0 of this regulation through the applicable coating analysis and capture system and control device efficiency test methods specified in Appendix B, Appendix D and Appendix E of this regulation and in accordance with the capture efficiency test methods in Appendix D of this regulation.

13.5.2.2 The control device is equipped with the applicable monitoring equipment specified in 2.0 of Appendix D of this regulation, and the monitoring equipment is installed, calibrated, operated, and maintained according to the vendor's specifications at all times the control device is in use.

13.6 Compliance procedures for EDP prime coat operations

13.6.1 The owner or operator of an EDP prime coat operation subject to 13.0 of this regulation shall use the procedures in 40 CFR 60.393(c)(1) (July 1, 1992 2009) to determine compliance if a capture system and a control device are not used to comply with the emission limits in 13.3.41.1 or 13.3.41.2 of this regulation.

13.6.2 The owner or operator of an EDP prime coat operation subject to 13.0 of this regulation shall use the procedures in 40 CFR 60.393(c)(2) (July 1, 1992 2009) to determine compliance if a capture system and a control device that destroys VOC (e.g., incinerator) are used to comply with the emission limits in 13.3.41.1 or 13.3.41.2 of this regulation.

13.6.3 The owner or operator of an EDP prime coat operation subject to 13.0 of this regulation shall use the procedures in 40 CFR 60.393(c)(3) (July 1, 1992 2009) to determine compliance if a capture system and a control device that recovers the VOC (e.g., carbon adsorber) are used to comply with the emission limits in 13.3.41.1 or 13.3.41.2 of this regulation.

13.7 Test methods

13.7.1 The test methods found in Appendix A through Appendix D of this regulation shall be used to determine compliance with 13.3.1, 13.3.2.2, 13.3.3.24.1 and 13.3.54.2, 13.3.6 and 13.3.7 of this regulation.

13.7.2 An owner or operator shall use the primer-surfacer and topcoat protocol to determine compliance with 13.3.1.32, 13.3.2.13 and 13.3.3.15 of this regulation. This protocol "Protocol for Determining the Daily Volatile Organic compound Emission Rate of Automobile and Light-duty Truck Primer-Surfacer and Topcoat Operations" EPA453/R-08-002, September 2008 can be found at www.epa.gov/ttn/oarpg/t1/ctg/autotruck_primer_topcoat_protocol_093008.pdf.

13.8 Recordkeeping and reporting for non-EDP prime coat, and final repair and miscellaneous motor vehicle materials coating operations.

13.8.1 An owner or operator of an automobile or light-duty truck coating operation that is exempt from the emission limitations in 13.3.14.1, 13.3.4.2 and 13.3.6 of this regulation shall comply with the certification, recordkeeping, and reporting requirements in 4.2 of this regulation.

13.8.2 An owner or operator of an automobile or light-duty truck coating operation subject to 13.0 of this regulation and complying with 13.3.14.1, 13.3.4.2 and 13.3.6 of this regulation by the use of complying coatings shall comply with the certification, recordkeeping, and reporting requirements in 4.3 of this regulation.

13.8.3 An owner or operator of an automobile or light-duty truck coating operation subject to 13.0 of this regulation and complying with 13.3.14.1, 13.3.4.2 and 13.3.6 of this regulation by daily-weighted averaging shall comply with the certification, recordkeeping, and reporting requirements in 4.4 of this regulation.

13.8.4 An owner or operator of an automobile or light-duty truck coating operation subject 13.0 of this regulation and complying with 13.3.14.1, 13.3.4.2 and 13.3.6 of this regulation by the use of control devices shall comply with the testing, reporting, and recordkeeping requirements in 4.5 of this regulation.

13.9 Recordkeeping and reporting for EDP prime coat operations. An owner or operator of an EDP prime coat operation subject to 13.0 of this regulation and complying with the requirements in 13.3.41.1, 13.3.41.2 and 13.3.41.3 of this regulation shall comply with the following:

13.9.1 Certification. By November 15, 1993 or upon startup of a new EDP prime coat operation, the owner or operator shall certify to the Department that the coating operation is and will be in compliance with the requirements in 13.3.41.1 or 13.3.41.2 of this regulation on and after November 15, 1993, or on and after the initial startup date. Such certification shall include:

13.9.1.1 The name and location of the facility.

13.9.1.2 The address and telephone number of the person responsible for the facility.

13.9.1.3 Identification of subject sources.

13.9.1.4 A copy of the calculations performed to determine RT and the calculations performed pursuant to 13.6 of this regulation to demonstrate compliance for the EDP prime coat operation for the month prior to submittal of the certification.

13.9.2 Recordkeeping. On and after November 15, 1993 or on and after the initial startup date of a new EDP prime coat operation, the owner or operator shall collect and record the following information for each EDP prime coat operation. These records shall be maintained at the facility for at least five years and shall be made available to the Department upon verbal or written request:

13.9.2.1 For each day, the total daily volume of coating solids that is added to the EDP system.

13.9.2.2 For each month, calculation of RT using the equation in 13.3.41.1 of this regulation.

13.9.2.3 For each month, the calculations used in the compliance determinations specified in 13.6 of this regulation.

13.9.3 Reporting. On and after November 15, 1993, the owner or operator of an EDP prime coat operation subject to 13.0 of this regulation shall notify the Department in either of the following instances:

13.9.3.1 Any record showing noncompliance with the appropriate emission limit for the EDP prime coat operation.

13.9.3.2 At least 30 calendar days before changing the method of compliance from one of the procedures in 13.6 of this regulation to another of the procedures in 13.6 of this regulation, the owner or operator shall comply with the certification requirements in 13.9.1 of this regulation.

13.10 Reporting and recordkeeping for topcoat and primer surfacer operations.

13.10.1 An owner or operator of an automobile or light-duty truck coating operation subject to 13.0 of this regulation and complying with 13.3.1.35, 13.3.2.14 or 13.3.3.1 of this regulation shall comply with the following:

13.10.1.1 Certification. At least 120 days prior to the initial compliance date, the owner or operator of a coating operation subject to the topcoat and primer surfacer limit in 13.3.1.35, 13.3.2.14 or 13.3.3.1 of this regulation shall submit to the Department a detailed proposal specifying the method of demonstrating how the compliance test will be conducted according to the topcoat protocol 13.7.2. The proposal shall include a comprehensive plan (including a rationale) for determining the transfer efficiency at each booth through the use of in-plant or pilot testing; the selection of coatings to be tested (for the purpose of determining transfer efficiency), including the rationale for coating groupings; and a method for tracking coating usage during the transfer efficiency test. Upon approval by the Department, the owner or operator may proceed with the compliance demonstration.

13.10.1.2 Recordkeeping

13.10.1.2.1 The owner or operator shall maintain at the facility for a period of 5 years all test results, data, and calculations used to determine VOC emissions from each topcoat and each primer surfacer operation according to the topcoat protocol.

13.10.1.2.2 If control devices are used to control emissions from an automobile or light-duty truck topcoat or primer surfacer operation, the owner or operator shall maintain records according to 4.5.2.6 through 4.5.2.11 of this regulation.

13.10.1.2.3 Reporting. Any instance of noncompliance with the emission limit in 13.3.1.35, 13.3.2.14 or 13.3.3.1 of this regulation shall be reported to the Department within 45 calendar days.

13.10.2 An owner or operator of an automobile or light-duty truck coating operation subject to 13.0 of this regulation and complying with 13.3.2.2 and 13.3.3.2 of this regulation by the use of complying coatings shall comply with the certification, recordkeeping, and reporting requirements in 4.3 of this regulation.

13.10.3 An owner or operator of an automobile or light-duty truck coating operation subject to 13.0 of this regulation and complying with 13.3.2.2 and 13.3.3.2 of this regulation by daily-weighted averaging shall comply with the certification, recordkeeping, and reporting requirements in 4.4 of this regulation.

13.10.4 An owner or operator of an automobile or light-duty truck coating operation subject to 13.0 of this regulation and complying with 13.3.2.2 and 13.3.3.2 of this regulation by the use of control devices shall comply with the testing, reporting and recordkeeping requirements 4.5 of this regulation.

(Break in Continuity of Sections)

01/11/1993 mm/dd/2010

16.1 Applicability

16.1.1 The provisions of 16.0 of this regulation apply to any paper, film, or foil coating unit.

16.1.2 The provisions of 16.0 of this regulation do not apply to any paper, film, or foil coating unit within a facility whose actual emissions (including related cleaning activities) without control devices from all paper, film, or foil coating units within the facility are less than 6.8 kilograms (kg) (15 pounds [lb]) of volatile organic compounds (VOCs) per day.

16.1.3 An owner or operator of a facility whose emissions are below the applicability threshold in 16.1.2 of this regulation shall comply with the certification, recordkeeping, and reporting requirements of 16.7.1 of this regulation.

16.1.4 Any facility that becomes or is currently subject to the provisions of 16.0 of this regulation by exceeding the applicability threshold in 16.1.2 of this regulation will remain subject to these provisions even if its emissions later fall below the applicability threshold.

16.1.5 Any facility that is currently subject to a state or federal rule promulgated pursuant to the Clean Air Act Amendments of 1977 by exceeding an applicability threshold is and will remain subject to these provisions, even if its throughput or emissions have fallen or later fall below the applicability threshold.

16.1.6 The provisions of 16.0 of this regulation does not apply to any coating unit in-line with any offset lithographic, screen, letterpress, flexographic, rotogravure, or digital printing operation. Such coating units may be subject to 37.0 or 47.0 of this regulation, whichever is applicable.

16.1.7 Transition period for existing permitted sources. Every owner or operator of any paper coating unit that is subject to a permit issued pursuant to 7 DE Admin. Code 1102 or 1130 containing all applicable conditions of 16.0 of this regulation, as that regulation existed on January 11, 1993, shall comply with those permit conditions until December 31, 2010. On and after January 1, 2011, every such owner or operator of any paper coating unit shall comply with the provisions of 16.0 of this regulation.

16.2 Definitions. As used in 16.0 of this regulation, all terms not defined herein shall have the meaning given them in the November 15, 1990 Clean Air Act Amendments (CAAA), or in 2.0 of this regulation.

"Coating" means a material being applied, or an action of applying such a material, onto or impregnated into a substrate for decorative, protective, or functional purpose.

“Paper, film, or foil coating line” means a web coating line where coating is applied to paper a series of coating applicators, flash-off areas, and any associated curing/drying equipment between one or more unwind/feed stations and one or more rewind/cutting stations to apply a coating onto a continuous strip of substrate (a web). Printing presses are not considered paper coating lines. Products produced on a paper, film, or foil coating line include, but are not limited to, adhesive tapes and labels, book covers, post cards, office copier paper, drafting paper, and pressure sensitive tapes and labels. Paper cCoating lines include, but are not limited to, application by impregnation or saturation or by the use of roll, knife, or rotogravure coating. A coating line may include more than one coating unit.

“Paper, film, or foil coating unit” means a coating application station and its associated flashoff area, drying area, or oven wherein coating is applied and dried or cured on a paper coating line. A paper coating line may include more than one paper coating unit any coating unit applying a coating to paper, film, or foil substrates used in the manufacturing of several major product types for the following industry sectors: pressure sensitive tape and labels (including fabric coated for use in pressure sensitive tapes and labels); photographic film; industrial and decorative laminates; abrasive products (including fabric coated for use in abrasive products) and flexible packaging (including coating of non-woven polymer substrates for use in flexible packaging). Paper, film, or foil coating unit also includes a coating unit applying a coating during miscellaneous coating operations for several products including: corrugated and solid fiber boxes; die-cut paper paperboard, and cardboard; converted paper and paperboard not elsewhere classified; folding paperboard boxes, including sanitary boxes; manifold business forms and related products; plastic aseptic packaging; and carbon paper and inked ribbons.

16.3 Standards. No owner or operator of any paper, film, or foil coating unit shall operate the coating unit unless the owner or operator meets the applicable requirements listed under 16.3.1, 16.3.2, 16.3.3, and 16.3.4 of this regulation.

16.3.1 Except as specified in 16.3.2 of this regulation, Nno owner or operator of a paper coating unit subject to 16.0 of this regulation shall cause, allow, or permit the application of any coating on that unit with VOC content in excess of 0.35 kilograms per liter (kg/L) (2.9 pounds per gallon [lb/gal]) of coating, excluding water and exempt compounds, as applied 0.40 kilogram VOC per kilogram of solid applied (kg/kg) (0.40 pound of VOC per pound of solid [lb/lb]).

16.3.2 For pressure sensitive tape and label surface coating, no application of any coating on that unit with VOC content in excess of 0.20 kilogram VOC per kilogram of solid applied (kg/kg) (0.20 pound of VOC per pound of solid [lb/lb]).

16.3.23 As an alternative to compliance with the emission limit in 16.3.1 or 16.3.2 of this regulation, an owner or operator of a paper, film, or foil coating unit subject to 16.0 of this regulation may meet the requirements of 16.4 or 16.5 of this regulation.

16.3.4 When handling cleaning materials, an owner or operator of a paper, film, or foil coating unit shall comply with 8.0 of this regulation.

16.4 Daily-weighted average limitation. No owner or operator of a paper, film, or foil coating unit subject to 16.0 of this regulation shall apply, during any day, coatings on that unit whose daily-weighted average VOC content, calculated in accordance with the procedure specified in Appendix C of this regulation, exceeds the emission limit in 16.3.1 or 16.3.2 of this regulation, whichever is applicable.

16.5 Control devices

16.5.1 An owner or operator of a paper, film, or foil coating unit subject to 16.0 of this regulation may comply with 16.0 of this regulation by:

16.5.1.1 Installing and operating a capture system on that unit.

16.5.1.2 Installing and operating a control device on that unit.

16.5.1.3 Determining for each day the overall emission reduction efficiency needed to demonstrate compliance. The overall emission reduction needed for a day is the lesser of the value calculated according to the procedure in 3.0 of Appendix C of this regulation for that day or 95%. If the calculated efficiency is less than 90%, use 90% as the needed efficiency.

16.5.1.4 Demonstrating each day that the overall emission reduction efficiency achieved for that day, as determined in 3.0 of Appendix D of this regulation, is greater than or equal to the overall emission reduction efficiency required needed for that day as determined in 16.5.1.3 of this regulation.

16.5.2 An owner or operator of a paper, film, or foil coating unit subject to 16.0 of this regulation shall ensure that:

16.5.2.1 A capture system and control device are operated at all times the coating unit is in operation, and the owner or operator demonstrates compliance with 16.0 of this regulation through the applicable coating analysis and capture system and control device efficiency test methods specified in Appendix B, Appendix D and Appendix E of this regulation and in accordance with the capture efficiency test methods in Appendix D of this regulation.

16.5.2.2 The control device is equipped with the applicable monitoring equipment specified in 2.0 of Appendix D of this regulation, and the monitoring equipment is installed, calibrated, operated, and maintained according to the vendor's specifications at all times the control device is in use.

16.6 Test methods. The test methods found in Appendix A through Appendix D of this regulation shall be used to determine compliance with 16.0 of this regulation.

16.7 Recordkeeping and reporting

16.7.1 An owner or operator of a paper, film, or foil coating unit that is exempt from the emission limitations in 16.3 of this regulation shall comply with the certification requirements in 4.2 of this regulation within six months after [insert the effective date of this revision of 16.0], and with the recordkeeping and reporting requirements in 4.2 of this regulation on and after [insert the effective date of this revision of 16.0].

16.7.2 An owner or operator of a paper, film, or foil coating unit subject to 16.0 of this regulation and complying with 16.3 of this regulation by the use of complying coatings shall comply with the certification requirements in 4.3 of this regulation within six months after [insert the effective date of this revision of 16.0], and with the recordkeeping and reporting requirements in 4.3 of this regulation on and after [insert the effective date of this revision of 16.0].

16.7.3 An owner or operator of a paper, film, or foil coating unit subject to 16.0 of this regulation and complying with 16.4 of this regulation by daily-weighted averaging shall comply with the certification, recordkeeping, and reporting requirements in 4.4 of this regulation.

16.7.4 An owner or operator of a paper, film, or foil coating unit subject to 16.0 of this regulation and complying with 16.5 of this regulation by the use of control devices shall comply with the testing requirements in 4.5 of this regulation within six months after [insert the effective date of this revision of 16.0], and with the reporting and recordkeeping requirements in 4.5 of this regulation on and after [insert the effective date of this revision of 16.0].

(Break in Continuity of Sections)

01/11/1993 mm/dd/2010

23.1 Applicability

23.1.1 The provisions of 23.0 of this regulation apply to any flat wood paneling coating line, except as specified in 23.1.2 of this regulation.

23.1.2 The provisions of 23.0 of this regulation do not apply to:

23.1.2.1 Aany flat wood paneling coating line within any facility whose actual emissions without control devices from all flat wood paneling coating lines within the facility are less than 6.8 kilograms (kg) (15 pounds [lb]) of volatile organic compounds (VOCs) per day.

23.1.2.2 Class I hardboard paneling finishes, particle board used in furniture, insulation board, exterior siding, tileboard, and softwood plywood coating lines.

23.1.3 An owner or operator of a facility whose emissions are below the applicability threshold in 23.1.2.1 of this regulation shall comply with the certification, recordkeeping, and reporting requirements of 23.7.1 of this regulation.

23.1.4 Any facility that becomes or is currently subject to the provisions of 23.0 of this regulation by exceeding the applicability threshold in 23.1.2.1 of this regulation will remain subject to these provisions even if its emissions later fall below the applicability threshold.

23.1.5 Any facility that is currently subject to a state or federal rule promulgated pursuant to the Clean Air Act Amendments of 1977 by exceeding an applicability threshold is and will remain subject to these provisions, even if its throughput or emissions have fallen or later fall below the applicability threshold.

23.2 Definitions. As used in 23.0 of this regulation, all terms not defined herein shall have the meaning given them in the November 15, 1990 Clean Air Act Amendments (CAAA), or in 2.0 of this regulation.

“Class I hardboard paneling finish” means finishes that meet the specifications for Class I of Voluntary Product Standard PS-59-73 as approved by the American National Standards Institute.

“Class II hardboard paneling finish” means finishes that meet the specifications for Class II of Voluntary Product Standard PS-59-73 as approved by the American National Standards Institute.

"Exterior siding" means wood panels with a flat surface made of solid wood, hardboard, or waferboard and are intended for use in commercial or residential construction, generally as a covering for an outside wall.

“Flat wood paneling coating line” means a coating line used to apply and dry or cure coatings applied to one of the following flat wood paneling product categories: printed interior panels made of hardwood plywood and thin particle board (i.e., less than or equal to 0.64 centimeter (cm) (0.25 inch [in.]) in thickness); natural finish hardwood plywood panels; and hardwood paneling with Class II finishes.

“Hardboard” is a panel manufactured primarily from inter-felted ligno-cellulosic fibers that are consolidated under heat and pressure in a hot press.

“Hardwood plywood” is plywood whose surface layer is a veneer of hardwood.

“Natural finish hardwood plywood panels” means panels whose original grain pattern is enhanced by essentially transparent finishes frequently supplemented by fillers and toners.

“Printed interior panels” means panels whose grain or natural surface is obscured by fillers and basecoats upon which a simulated grain or decorative pattern is printed.

“Thin particleboard” is a manufactured board that is 0.64 cm (0.25 in.) or less in thickness made of individual wood particles that have been coated with a binder and formed into flat sheets by pressure.

“Tileboard” means paneling that has a colored, waterproof surface coating paneling that meets the specifications for Class I hardboard given by the standard ANSI/AHA A135.4-1995 as approved by the American National Standards Institute. The standard specifies requirements and test methods for water absorption, thickness swelling, modulus of rupture, tensile strength, surface finish, dimensions, squareness, edge straightness, and moisture content for five classes of hardboard. Tileboard is also known as Class I hardboard or tempered hardboard.

23.3 Standards

23.3.1 No owner or operator of a flat wood paneling coating line subject to 23.0 of this regulation shall cause or allow, on any day, VOC emissions from the coating of any one of the following flat wood paneling product categories in excess of the emission limits in 23.3.1.1 though 23.3.1.2 Table 23-1 of this regulation:

Flat wood paneling product category | kg/100m2 a | lb/1,000ft2 a | |

23.3.1.1 23.3.1.2 23.3.1.3 | Printed interior panels Natural finish hardwood plywood panels Class II finish on hardboard panels | 2.9 5.8 4.8 | 6.0 12.0 10.0 |

a VOC content values are expressed in units of mass of VOC (kg, lb) per area of coated finished product (100 square meters [m2], 1,000 square feet [ft2])

Table 23-1. VOC Emission Limits from Flat Wood Paneling Coatings.

Flat Wood Paneling Product Category | VOC Content Limits in Coatings, Inks, or Adhesives Being Applied | |

lb/gal | g/L | |

Printed interior panels made of hardwood, plywood, or thin particleboard | 2.1* | 250 |

Natural finish hardwood plywood panels | 2.1 | 250 |

Class II finishes on hardboard panels | 2.1 | 250 |

Tileboard | 2.1 | 250 |

Exterior siding | 2.1 | 250 |

*This limit of 2.1 lb/gal is equivalent to 5.0 lb VOC per 1,000 ft2 coating area.

23.3.2 As an alternative to compliance with the emission limits in 23.3.1 of this regulation, an owner or operator of a flat wood paneling coating line may meet the requirements of 23.5 of this regulation.

23.4 [Reserved] Work Practice Standards. No owner or operator of a flat wood paneling coating line subject to 23.0 of this regulation shall perform coating operation of any flat wood paneling category in Table 23-1 of this regulation unless the owner or operator meets the work practice requirements of 8.0 of this regulation.

23.5 Control devices

23.5.1 An owner or operator of a flat wood paneling coating line subject to 23.0 of this regulation may comply with 23.0 of this regulation by:

23.5.1.1 Installing and operating a capture system on that line.

23.5.1.2 Installing and operating a control device on that line.

23.5.1.3 Determining for each day the overall emission reduction efficiency needed to demonstrate compliance. The overall emission reduction needed for a day is the lesser of the value calculated according to the procedure in 23.6.2 of this regulation for that day or 95%. greater of:

23.5.1.3.1 lesser of the value calculated according to the procedure in 23.6.2 of this regulation for that day or 95%, or

23.5.1.3.2 90%.

23.5.1.4 Demonstrating each day that the overall emission reduction efficiency achieved for that day, as determined in 5.0 of Appendix D of this regulation, is greater than or equal to the overall emission reduction efficiency required needed for that day as determined in 23.5.1.3 of this regulation.

23.5.2 An owner or operator of a flat wood paneling coating line subject to 23.0 of this regulation shall ensure that:

23.5.2.1 A capture system and control device are operated at all times that the line is in operation, and the owner or operator demonstrates compliance with 23.0 of this regulation through the applicable coating analysis and capture system and control device efficiency test methods specified in Appendix B, Appendix D and Appendix E of this regulation and in accordance with the capture efficiency test methods in Appendix D of this regulation.

23.5.2.2 The control device is equipped with the applicable monitoring equipment specified in 2.0 of Appendix D of this regulation, and the monitoring equipment is installed, calibrated, operated, and maintained according to the vendor's specifications at all times the control device is in use.

23.6 Test Methods and Efficiency of Control System

23.6.1 Test methods. The test methods found specified in 23.6, of this regulation and in Appendix A, Appendix B and Appendix D of this regulation shall be used to determine compliance.

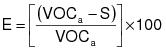

23.6.2 Overall emission reduction efficiency for control systems. The required overall emission reduction efficiency of the control system for the day shall be calculated according to the following equation:

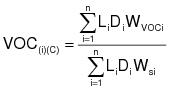

where:

E = The required overall emission reduction efficiency of the control system for the day.

VOCa = The maximum VOC content of the coatings, as applied, used each day on a coating line in units of kg VOC/100 m2 of coated finished product (lb VOC/1,000 ft2), lb VOC/gal of coating material applied (or kg VOC/L of coating material applied), as determined by the applicable test methods and procedures specified in Appendix B of this regulation.

S = applicable VOC emission limitation in Table 23-1 of this regulation in terms of kg VOC/100 m2 of coated finished product (lb VOC/1,000 ft2) lb VOC/gal of coating material applied (or kg VOC/L of coating material applied).

23.7 Recordkeeping and reporting

23.7.1 Requirements for coating sources exempt from emission limitations. An owner or operator of a flat wood paneling coating line that is exempt from the emission limitations of 23.3 of this regulation because combined VOC emissions on any day from all flat wood paneling coating lines at the facility are below the applicability threshold specified in 23.1.2.1 of this regulation, before the application of capture systems and control devices, shall comply with the following:

23.7.1.1 Certification. By November 15, 1993, Within six months after [insert the effective date of this revision of 23.0], the owner or operator of a facility referenced specified in 23.7.1 of this regulation shall certify to the Department that the facility is exempt by providing the following:

23.7.1.1.1 The name and location of the facility.

23.7.1.1.2 The address and telephone number of the person responsible for the facility.

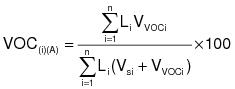

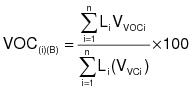

23.7.1.1.3 A declaration that the facility is exempt from the emission limitations of 23.3 of this regulation because combined VOC emissions on any day from all flat wood paneling coating lines at the facility are below the applicability threshold before the application of capture systems and control devices. The following equation shall be used to calculate total VOC emissions for that day:

where:

T = Total VOC emissions from coating lines at the facility for each category of flat wood paneling (as specified in 23.3.1 of this regulation) before the application of capture systems and control devices in units of kg VOC/day (lb VOC/day).

n = Number of different coatings applied on each coating line at the facility.

i = Subscript denoting an individual coating.

C = Mass of VOC per area of coated finished product in units of kg VOC/100 m2 (lb VOC/1,000 ft2).

D = The surface area coated at the facility each day in units of m2/day (ft2/day).

a = Constant = 100 m2 if using metric units.

= 1,000 ft2 if using English units.

23.7.1.2 Recordkeeping. On and after November 15, 1993 [insert the effective date of this revision of 23.0], the owner or operator of a facility referenced specified in 23.7.1 of this regulation shall collect and record all of the following information each day and maintain the information at the facility for a period of five years:

23.7.1.2.1 The name and identification number of each coating, as applied, used to coat each type of flat wood paneling product.

23.7.1.2.2 The volume of coating (i) (excluding water and exempt compounds), as applied, used each day to coat each type of flat wood paneling product (specified in 23.3.1 of this regulation), and the surface area coated each day of each type of flat wood paneling product.

23.7.1.2.3 The total VOC emissions at the facility, as calculated using the equation under 23.7.1.1.3 of this regulation.

23.7.1.3 Reporting. On and after November 15, 1993 [insert the effective date of this revision of 23.0], the owner or operator of a facility referenced specified in 23.7.1 of this regulation shall notify the Department of any record showing that combined VOC emissions from all coating lines at the coating facility exceed 6.8 kg (15 lb) on any day, before the application of capture systems and control devices. A copy of such record shall be sent to the Department within 45 calendar days after the exceedance occurs. This requirement is in addition to any other exceedance reporting requirements mandated by the State of Delaware.

23.7.2 Requirements for coating sources using complying coatings. An owner or operator of a flat wood paneling coating line subject to 23.0 of this regulation and complying with 23.3 of this regulation by means of the use of complying coatings shall comply with the following:

23.7.2.1 Certification. By November 15, 1993 Within six months after [insert the effective date of this revision of 23.0], or upon startup of a new coating line, or upon changing the method of compliance for an existing coating line from control devices to the use of complying coatings, the owner or operator of a coating line referenced specified in 23.7.2 of this regulation shall certify to the Department that the coating line is or will be in compliance with the requirements of the applicable section of this regulation on and after November 15, 1993 [insert the effective date of this revision of 23.0], or on and after the initial startup date. Such certification shall include:

23.7.2.1.1 The name and location of the facility.

23.7.2.1.2 The address and telephone number of the person responsible for the facility.

23.7.2.1.3 Identification of subject sources.

23.7.2.1.4 The name and identification number of each coating, as applied, used to coat each type of flat wood paneling product.

23.7.2.1.5 The mass of VOC per area of coated finished product The VOC content of each coating for each type of flat wood paneling product (specified in 23.3.1 of this regulation) in terms of kg VOC/100 m2 (lb VOC/1,000 ft2) lb VOC/gal of coating material applied (or kg VOC/L of coating material applied) and the surface area volume of each coating (in terms of gal or L) coated each day of each type of flat wood paneling product.

23.7.2.2 Recordkeeping. On and after November 15, 1993 [insert the effective date of this revision of 23.0], or on and after the initial startup date, the owner or operator of a coating line referenced in 23.7.2 of this regulation and complying by the use of complying coatings shall collect and record all of the following information each day for each coating line and maintain the information at the facility for a period of five years:

23.7.2.2.1 The name and identification number of each coating, as applied, used to coat each type of flat wood paneling product.

23.7.2.2.2 The mass of VOC per area of coated finished product The VOC content of each coating for each type of flat wood paneling product (specified in 23.3.1 of this regulation) for each coating used each day in terms of kg VOC/100 m2 (lb VOC/1,000 ft2) lb VOC/gal of coating material applied (or kg VOC/L of coating material applied) and the surface area volume of each coating (in terms of gal or L) coated each day of each type of flat wood paneling product.

23.7.2.3 Reporting. On and after November 15, 1993 [insert the effective date of this revision of 23.0], the owner or operator of a flat wood paneling coating line referenced in 23.7.2 of this regulation shall notify the Department in either of the following instances:

23.7.2.3.1 Any record showing use of any noncomplying coatings shall be reported by sending a copy of such record to the Department within 45 calendar days following that use. This reporting requirement is in addition to any other exceedance reporting mandated by the State of Delaware.

23.7.2.3.2 At least 30 calendar days before changing the method of compliance from the use of complying coatings to control devices, the owner or operator shall comply with all requirements of 23.7.3.1 of this regulation, as well as 7 DE Admin. Code 1102. Upon changing the method of compliance from the use of complying coatings to control devices, the owner or operator shall comply with all requirements of the section applicable to the coating line referenced in 23.7.3 of this regulation.

23.7.3 Requirements for coating sources using control devices. Any owner or operator of a flat wood paneling coating line subject to 23.0 of this regulation and complying with 23.3 of this regulation by the use of control devices shall comply with the following:

23.7.3.1 Testing of control equipment. By November 15, 1993 Within six months after [insert the effective date of this revision of 23.0], or upon startup of a new coating line, or upon changing the method of compliance for an existing coating line from the use of complying coatings to control devices, the owner or operator of the subject coating line shall perform a compliance test. Testing shall be performed within 90 days of startup, and pursuant to the procedures in Appendix A, Appendix B and Appendix D of this regulation and 23.6 of this regulation. The owner or operator of the subject coating line shall submit to the Department the results of all tests and calculations necessary to demonstrate that the subject coating line is or will be in compliance with the applicable section of this regulation on and after November 15, 1993 [insert the effective date of this revision of 23.0], or on and after the initial startup date.

23.7.3.2 Recordkeeping. On and after November 15, 1993 [insert the effective date of this revision of 23.0], or on and after the initial startup date, the owner or operator of a coating line referenced in 23.7.3 of this regulation shall collect and record all of the following information each day for each coating line and maintain the information at the facility for a period of five years:

23.7.3.2.1 The name and identification number of each coating used on each coating line, as applied, used to coat each type of flat wood paneling product.

23.7.3.2.2 The mass of VOC per area of coated finished product The VOC content of each coating for each type of flat wood paneling product (specified in 23.3.1 of this regulation) in terms of kg VOC/100 m2 (lb VOC/1,000 ft2) lb VOC/gal of coating material applied (or kg VOC/L of coating material applied), and the surface area volume of each coating (in terms of gal or L) coated each day of each type of flat wood paneling product.

23.7.3.2.3 The maximum VOC content of the coatings, as applied, used each day (mass of VOC per area of coated finished product in terms of kg VOC/100 m2 [lb VOC/1,000 ft2]) (in terms of lb VOC/gal of coating material applied [or kg VOC/L of coating material applied].

23.7.3.2.4 The required overall emission reduction efficiency for each day for each coating line as determined in 23.6.2 of this regulation.

23.7.3.2.5 The actual overall emission reduction efficiency achieved for each day for each coating line as determined in 3.0 of Appendix D of this regulation.

23.7.3.2.6 Control device monitoring data.

23.7.3.2.7 A log of operating time for the capture system, control device, monitoring equipment, and the associated coating line.

23.7.3.2.8 A maintenance log for the capture system, control device, and monitoring equipment detailing all routine and non-routine maintenance performed including dates and duration of any outages.

23.7.3.2.9 For thermal incinerators, all 3-hour periods of operation in which the average combustion temperature was more than 28°C (50°F) below the average combustion temperature during the most recent performance test that demonstrated that the facility was in compliance. The combustion chamber set-point shall be no less than that during the most recent performance test that demonstrated that the facility was in compliance.

23.7.3.2.10 For catalytic incinerators, all three-hour periods of operation in which the average temperature of the process vent stream immediately before the catalyst bed is more than 28°C (50°F) below the average temperature of the process vent stream immediately before the catalyst bed during the most recent performance test that demonstrated that the facility was in compliance. The set-point for the process vent stream immediately before the catalyst bed shall be no less than that during the most recent performance test that demonstrated that the facility was in compliance.

23.7.3.2.11 For carbon adsorbers, all three-hour periods of operation during which either the average VOC concentration or the reading of organics in the exhaust gases is more than 20% greater than the average exhaust gas concentration or reading measured by the organics monitoring device during the most recent determination of the recovery efficiency of the carbon adsorber that demonstrated that the facility was in compliance.

23.7.3.3 Reporting. On and after November 15, 1993 [insert the effective date of this revision of 23.0], the owner or operator of a subject coating line referenced in 23.7.3 of this regulation shall notify the Department in the following instances:

23.7.3.3.1 Any record showing noncompliance with the applicable requirements for control devices shall be reported by sending a copy of the record to the Department within 45 calendar days following the occurrence. This requirement is in addition to any other exceedance reporting mandated by the State of Delaware.

23.7.3.3.2 At least 30 calendar days before changing the method of compliance from control devices to the use of complying coatings, the owner or operator shall comply with all requirements of 23.7.2.1 of this regulation, and 7 DE Admin. Code 1102. Upon changing the method of compliance from control devices to the use of complying coatings, the owner or operator shall comply with all requirements of the Section applicable to the coating line referenced in 23.7.2 of this regulation.

(Break in Continuity of Sections)

11/29/1994 xx/xx/2010

37.1 Applicability

37.1.1 The provisions of 37.0 of this regulation apply to any packaging rotogravure, publication rotogravure, or flexographic printing press at any facility whose maximum theoretical emissions of volatile organic compounds (VOCs) (including solvents used to clean each of these printing presses) without control devices from all printing presses are greater than or equal to 7.7 tons per year. on and after [insert effective date of this regulation], and

37.1.2 Transition period for existing permitted sources. Every owner or operator of press that is subject to 37.5.1.2.2 of this regulation and that is covered by a permit issued pursuant to 7 DE Admin. Code 1102 or 1130 containing all applicable conditions of 37.0 of this regulation, as that regulation existed on November 29, 1994, shall comply with those permit conditions until December 31, 2010. On and after January 1, 2011, every such owner or operator of any flexible package printing facility shall comply with the provisions of 37.0 of this regulation.

37.1.23 An owner or operator of a facility whose emissions are below the applicability thresholds in 37.1.1 and 37.5.1.2.2 of this regulation shall comply with the certification, recordkeeping, and reporting requirements of 37.7.1 of this regulation.

37.1.34 Any facility that becomes or is currently subject to the provisions of 37.0 of this regulation by exceeding the applicability thresholds in 37.1.1 and 37.5.1.2.2 of this regulation will remain subject to these provisions even if its emissions later fall below the applicability thresholds.

37.1.45 Any facility that is currently subject to a state or federal rule promulgated pursuant to the Clean Air Act Amendments of 1977 by exceeding an applicability threshold is and will remain subject to these provisions, even if its throughput or emissions have fallen or later fall below the applicability threshold.

37.2 Definitions. As used in 37.0 of this regulation, all terms not defined herein shall have the meaning given them in the November 15, 1990 Clean Air Act Amendments, or in 2.0 of this regulation.

"Add-on air pollution control device (APCD)" means an emission control device or system that is originally separated from an emission source but can be later added or installed to the emission source to reduce emission from the source.

"Flexible packaging" means any package or part of a package the shape of which can be readily changed. Flexible packaging includes, but is not limited to, bags, pouches, liners, and wraps utilizing paper, plastic, film, aluminum foil, metalized or coated paper or film, or any combination of these materials.

"Flexible packaging printing" means printing, coating and laminating activities being performed on or in-line with a flexible packaging printing press.

“Flexographic printing press” means a printing press that uses a roll printing technique in which the pattern to be applied is raised above the printing roll and the image carrier is made of rubber or other elastomeric materials.

“Packaging rotogravure printing press” means a rotogravure printing press used to print on paper, paper board, metal foil, plastic film, and other substrates that are, in subsequent operations, formed into packaging products and labels, and other nonpublication products.

“Press-Ready Ink” means ink, as applied to a substrate, after all solvents and diluents have been added.

“Printing press” means equipment used to apply words, pictures, or graphic designs to either a continuous substrate or a sheet. A continuous substrate consists of paper, plastic, or other material that is unwound from a roll, passed through coating or ink applicators and any associated drying areas. The press includes all coating and ink applicators and drying areas between unwind and rewind of the continuous substrate. A sheet consists of paper, plastic, or other material that is carried through the process on a moving belt. The press includes all coating and ink applicators and drying operations between the time that the sheet is put on the moving belt until it is taken off.

“Publication rotogravure printing press” means a rotogravure printing press on which the following paper products are printed:

1. Catalogues, including mail order and premium.

2. Direct mail advertisements, including circulars, letters, pamphlets, cards, and printed envelopes.

3. Display advertisements, including general posters, outdoor advertisements, car cards, window posters; counter and floor displays; points-of-purchase, and other printed display material.

4. Magazines, books.

5. Miscellaneous advertisements, including brochures, pamphlets, catalogue sheets, circular folders, announcements, package inserts, book jackets, market circulars magazine inserts, and shopping news.

6. Newspapers, magazine and comic supplements for newspapers, and preprinted newspaper inserts, including hi-fi and spectacolor rolls and Sections.