DEPARTMENT OF HEALTH AND SOCIAL SERVICES

Division Of Public Health

Authority On Radiation Protection

FINAL

ORDER

4465 Delaware Radiation Control Regulations

NATURE OF THE PROCEEDINGS:

Delaware Health and Social Services ("DHSS") initiated proceedings to amend five sets of the State of Delaware Regulations Governing Radiation Control. The DHSS proceedings to amend regulations were initiated pursuant to 29 Del.C. §101 and authority as prescribed by 16 Del.C. §7405. The five sets amended are shown in the table below.

|

DE Admin. Code No.

|

Current Delaware Citation

|

Title

|

|

4482

|

Part C

|

Licensing of Radioactive Material

|

|

4485

|

Part F

|

Use of Diagnostic X-Rays in the Healing Arts

|

|

4486

|

Part G

|

Use of Radionuclides in the Healing Arts

|

|

4490

|

Part K

|

Compliance Procedures

|

|

4492

|

Part X

|

Therapeutic Radiation Machines

|

On March 1, 2013 (Volume 16, Issue 9), DHSS published in the Delaware Register of Regulations its notice of proposed regulations, pursuant to 29 Del.C. §10115. It requested that written materials and suggestions from the public concerning the proposed regulations be delivered to DHSS by April 8, 2013, or be presented at a public hearing on March 22, 2013, after which time the DHSS would review information, factual evidence and public comment to the said proposed regulations.

Written comments were received during the public comment period and evaluated. The results of that evaluation are summarized in the accompanying "Summary of Evidence."

SUMMARY OF EVIDENCE

In accordance with Delaware Law, public notices regarding proposed Department of Health and Social Services (DHSS) Regulations Governing Radiation Control were published in the Delaware State News, the News Journal and the Delaware Register of Regulations.

Written comments were received on the proposed regulations during the public comment period (March 1, 2013 through April 8, 2013). Entities offering comments included:

Mr. Reed W. Best, Director of Regulatory and Quality Affairs, Aribex, Inc.

Public comments and the DHSS (Agency) responses are as follows:

Aribex is the developer and manufacturer of hand-held x-ray devices that are sold throughout the United States and in many other nations around the world for use in the dental, veterinarian, and forensic medicine. Currently Aribex distributes these units under the names of the NOMAD, NOMAD Pro, and the NOMAD eXaminer. All of these devices are manufacturer at the Aribex facilities in Orem, Utah. As a supplier of these hand-held x-ray units, the repeal of the current Part F and the addition of DE Admin Code No. 4485, Use of Diagnostic X-Rays in the Healing Arts are of direct importance to Aribex.

Aribex feels that the provisions in the proposed regulations are prudent and appropriate for the generic class of hand-held x-ray units. However, in order to reduce the administrative workload on both the staff of the Office of Radiation Control (ORC) and the regulated community, we would suggest that provisions be made either in the regulations or in the policies/procedures of the ORC to allow changes in these requirements based upon a demonstration by the manufacturer of a device that its device(s) are safe and efficacious.

California has issued Exemption to California Code of Regulations dated March 13, 2013, (copy is attached) which uses this approach:

“…exemption is made for users of the Aribex Nomad, Aribex Nomad Pro, and Aribex Nomad eXaminer, based on seven years of exposure data. Users of these portable hand-held X-ray systems are not required to comply with the personnel monitoring requirement found in condition 3. The personnel monitoring requirements may be reevaluated for other units after sufficient historical exposure data has been obtained and submitted, by the manufacturer, to the Department for review.”

Attached is a comparison of the requirements in the proposed regulations and what we suggest are appropriate requirements for the NOMAD devices. Specifically the differences are that the users of the NOMAD devices should not be required to use the device on a stand, should not be required to wear a leaded apron when operating the NOMAD, and should not be required to provide personnel monitoring devices for operators of the NOMAD.

These requirements, which are not required for operators of conventional wall mounted x-ray units, were put in place out of a need for an abundance of caution when the NOMAD was a new and unfamiliar device. Now with over seven years of clinical usage and over 11,000 NOMAD units in use across the United States, the NOMAD is no longer new or unfamiliar, but rather a proven safe and efficacious device. Therefore, Aribex requests that you reconsider these requirements for operators of the NOMAD.

The requirement for personnel monitoring in Delaware regulations applies to persons who may receive 10% or more of the annual radiation dose limit. In the numerous studies of operator doses associated with the use of the NOMAD, no study of radiation doses has ever shown anywhere near this level of exposure for operators of the NOMAD.

I believe that the staff of ORC has been provided with copies of many of these studies, but if you have not I will be happy to see that they are sent to you for your review. I have attached copies of two peer-reviewed studies on radiation doses to operators of the NOMAD published in 2012 in case you have not seen them. The first paper was published in Health Physics in February 2012 and the second was published in the Health Physics Society journal Operational Radiation Safety in August 2012. These studies, like all the previous studies, demonstrate that the radiation doses to operators of the NOMAD are extremely small and well below the 10% limit requiring personnel monitoring.

Aribex shares your concern that while the NOMAD has repeatedly been shown to be a safe and efficacious hand-held x-ray unit, there are other hand-held x-ray units available to users in Delaware that have not been designed and manufactured with the safety and radiation protection features inherent in the NOMAD. To our knowledge these units have not under gone the extensive radiation safety testing that the NOMAD has undergone.

The Washington radiation control program tested four different hand-held x-ray units including the NOMAD and found markedly different potential radiation exposures between the devices. Attached is a copy of the data from that study. Based on this study the State of Washington has adopted regulations that address the different levels of potential radiation exposure to the operators associated with various devices. A copy of the current Washington regulations that base the level of required additional protective devices based on potential radiation exposure to the operator is also attached. Delaware may want to consider providing similar criteria in its regulations or implementation guidance.

If Aribex can help the State of Delaware in its process of adopting its new regulations, please let me know.

Thank you for your time and consideration of our comments and suggestions.

Agency Response: The Agency appreciates and acknowledges your comment but respectfully will not adopt your recommendation, as the proposed regulation allows permitted facilities to utilize a conditional variance application process if they wish to use hand-held x-ray devices in the healing arts. In Delaware, permitted facilities have standing to request exemption or variance for utilization of any device approved by the FDA that they see as necessary in their practice, and the state inspects such facilities to assess operational safety and health protection regulatory compliance. The state has historically relied upon, and will continue to rely upon the federal Food & Drug Administration (FDA) to approve radiation-emitting manufactured devices for sale and distribution in the United States.

Verifying documents are attached to the Hearing Officer’s record. The regulation has been approved by the Delaware Attorney General’s office and the Cabinet Secretary of DHSS.

FINDINGS OF FACT:

Based on public comments received, non-substantive changes were made to the proposed regulations. The Department finds that the proposed regulations, as set forth in the attached copy should be adopted in the best interest of the general public of the State of Delaware.

THEREFORE, IT IS ORDERED, that the proposed State of Delaware Regulations Governing Radiation Control are adopted and shall become effective June 11, 2013, after publication of the final regulation in the Delaware Register of Regulations.

Rita M. Landgraf, Secretary

This part provides for the licensing of radioactive material, for purposes of protecting the public health and safety. No person shall receive, possess, use, transfer, sell, own or acquire radioactive material except as authorized in a specific or general license per the U.S. Nuclear Regulatory Commission (NRC), in accordance with Title 10 – Code of Federal Regulations. Primary radioactive material licensing and enforcement authority was transferred to the NRC in 2007, pursuant to the Federal Energy Policy Act of 2005. However, radioactive material facilities must be registered with the State of Delaware in accordance with 4481/Part B of these regulations.

Part F

This Part establishes requirements, for which a registrant is responsible, for use of diagnostic x-ray equipment by, or under the supervision of, an individual authorized by and licensed in accordance with State statutes to engage in the healing arts or veterinary medicine. The provisions of this Part are in addition to, and not in substitution for, other applicable provisions of Parts A, B, D, J and K of the regulations. Some registrants may also be subject to the requirements of Parts I and X of the regulations.

As used in this Part, the following definitions apply:

"Accessible surface" means the external surface of the enclosure or housing of the radiation producing machine as provided by the manufacturer.

"Accessory component" means:

(1) A component used with diagnostic x-ray systems, such as a cradle or film changer, that is not necessary for the compliance of the system with applicable provisions of this Part but which requires an initial determination of compatibility with the system; or

(2) A component necessary for compliance of the system with applicable provisions of this Part but which may be interchanged with similar compatible components without affecting the system’s compliance, such as one of a set of interchangeable beam-limiting devices; or

(3) A component compatible with all x-ray systems with which it may be used and that does not require compatibility or installation instructions, such as a tabletop cassette holder.

"Air kerma" means kerma in air (see definition of Kerma).

"Air kerma rate (AKR)" means the air kerma per unit time.

"Aluminum equivalent" means the thickness of type 1100 aluminum alloy (The nominal chemical composition of type 1100 aluminum is 99.00 percent minimum aluminum, 0.12 percent copper.) affording the same attenuation, under specified conditions, as the material in question.

"Articulated joint" means a joint between two separate sections of a tabletop which joint provides the capacity of one of the sections to pivot on the line segment along which the sections join.

"Assembler" means any person engaged in the business of assembling, replacing, or installing one or more components into an x-ray system or subsystem. The term includes the owner of an x-ray system or his or her employee or agent who assembles components into an x-ray system that is subsequently used to provide professional or commercial services.

"Attenuation block" means a block or stack, having dimensions 20 centimeters by 20 centimeters by 3.8 centimeters, of type 1100 aluminum alloy (The nominal chemical composition of type 1100 aluminum is 99.00 percent minimum aluminum, 0.12 percent copper.) or other materials having equivalent attenuation.

"Automatic exposure control (AEC)" means a device which automatically controls one or more technique factors in order to obtain at a preselected location(s) a required quantity of radiation (Includes devices such as phototimers and ion chambers).

"Automatic exposure rate control (AERC)" means a device which automatically controls one or more technique factors in order to obtain, at a preselected location(s), a required quantity of radiation per unit time.

"Barrier" (See "Protective barrier").

"Beam axis" means a line from the source through the centers of the x-ray fields.

"Beam-limiting device" means a device which provides a means to restrict the dimensions of the x- ray field.

"Bone densitometry system" means a medical device which uses electronically-produced ionizing radiation to determine the density of bone structures of human patients.

"C-arm fluoroscope" means a fluoroscopic x-ray system in which the image receptor and the x-ray tube housing assembly are connected or coordinated to maintain a spatial relationship. Such a system allows a change in the direction of the beam axis with respect to the patient without moving the patient.

"Cantilevered tabletop" means a tabletop designed such that the unsupported portion can be extended at least 100 cm beyond the support.

"Cassette holder" means a device, other than a spot-film device, that supports and/or fixes the position of an x-ray film [imaging] cassette during an x-ray exposure.

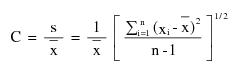

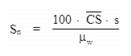

"Coefficient of variation (C)" means the ratio of the standard deviation to the mean value of a population of observations. It is estimated using the following equation:

where:

= Estimated standard deviation of the population.

= Estimated standard deviation of the population.

= Mean value of observations in sample;

= Mean value of observations in sample;

= ith observation in sample;

= ith observation in sample;

n = Number of observations sampled.

"Computed tomography (CT)" means the production of a tomogram by the acquisition and computer processing of x-ray transmission data.

"Control panel" means that part of the x-ray control upon which are mounted the switches, knobs, pushbuttons, and other hardware necessary for manually setting the technique factors.

"Cooling curve" means the graphical relationship between heat units stored and cooling time.

"Cradle" means:

(1) A removable device which supports and may restrain a patient above an x-ray table; or

(2) A device;

(i) Whose patient support structure is interposed between the patient and the image receptor during normal use;

(ii) Which is equipped with means for patient restraint; and

(iii) Which is capable of rotation about its long (longitudinal) axis.

"CT" (See "Computed tomography").

"CT gantry" means tube housing assemblies, beam-limiting devices, detectors, and the supporting structures, frames, and covers which hold and/or enclose these components.

"Cumulative air kerma" means the total air kerma accrued from the beginning of an examination or procedure and includes all contributions from fluoroscopic and radiographic irradiation.

"Detector" (See "Radiation detector")

"Diagnostic source assembly" means the tube housing assembly with a beam-limiting device attached.

"Diagnostic x-ray system" means an x-ray system designed for irradiation of any part of the human [or animal] body for the purpose of diagnosis or visualization.

"Direct scattered radiation" means that scattered radiation which has been deviated in direction only by materials irradiated by the useful beam (See "Scattered radiation").

"Dose" means the absorbed dose as defined by the International Commission on Radiation Units and Measurements. The absorbed dose, D, is the quotient of de by dm, where de is the mean energy imparted to matter of mass dm; thus D=de/dm, in units of J/kg, where the special name of the unit of absorbed dose is gray (Gy).

"Equipment" (See "X-ray equipment").

"Exposure (X)" means the quotient of dQ by dm where dQ is the absolute value of the total charge of the ions of one sign produced in air when all the electrons and positrons liberated or created by photons in air of mass dm are completely stopped in air; thus X=dQ/dm, in units of C/kg. A second meaning of exposure is the process or condition during which the x-ray tube produces x-ray radiation.

"Field emission equipment" means equipment which uses an x-ray tube in which electron emission from the cathode is due solely to the action of an electric field.

"Filter" means material placed in the useful beam to preferentially absorb selected radiations.

"Fluoroscopic air kerma display devices" means separate devices, subsystems, or components that provide the display of AKR and cumulative air kerma, respectively, required by 5.0. They include radiation detectors, if any, electronic and computer components, associated software, and data displays.

"Fluoroscopic imaging assembly" means a subsystem in which x-ray photons produce a set of fluoroscopic images or radiographic images recorded from the fluoroscopic image receptor. It includes the image receptor(s), electrical interlocks, if any, and structural material providing linkage between the image receptor and diagnostic source assembly.

"Fluoroscopic irradiation time" means the cumulative duration during an examination or procedure of operator-applied continuous pressure to the device, enabling x-ray tube activation in any fluoroscopic mode of operation.

"Fluoroscopy" means a technique for generating x-ray images and presenting them simultaneously and continuously as visible images. This term has the same meaning as the term “radioscopy” in the standards of the International Electrotechnical Commission.

"Focal spot (actual)" means the area projected on the anode of the x-ray tube bombarded by the electrons accelerated from the cathode and from which the useful beam originates.

"General purpose radiographic x-ray system" means any radiographic x-ray system which, by design, is not limited to radiographic examination of specific anatomical regions.

"Gonad shield" means a protective barrier for the testes or ovaries.

"Half-value layer (HVL)" means the thickness of specified material which attenuates the beam of radiation to an extent such that the AKR is reduced by one-half of its original value. In this definition, the contribution of all scattered radiation, other than any which might be present initially in the beam concerned, is deemed to be excluded.

"Hand-held x-ray equipment" means x-ray equipment that is designed to be hand-held during operation.

"Healing arts screening" means the testing of human beings using x-ray machines for the detection or evaluation of health indications when such tests are not specifically and individually ordered by a licensed practitioner of the healing arts legally authorized to prescribe such x-ray tests for the purpose of diagnosis or treatment.

"Heat unit" means a unit of energy equal to the product of the peak kilovoltage, milliamperes, and seconds, i.e., kVp x mA x second.

"HVL" (See "Half-value layer").

"Image intensifier" means a device, installed in its housing, which instantaneously converts an x-ray pattern into a corresponding light image of higher intensity.

"Image receptor" means any device, such as a fluorescent screen, radiographic film, x-ray image intensifier tube, solid-state detector, or gaseous detector which transforms incident x-ray photons either into a visible image or into another form which can be made into a visible image by further transformations. In those cases where means are provided to preselect a portion of the image receptor, the term “image receptor” shall mean the preselected portion of the device.

"Image receptor support device" means, for mammography x-ray systems, that part of the system designed to support the image receptor during a mammographic examination and to provide a primary protective barrier.

"Irradiation" means the exposure of matter to ionizing radiation.

"Isocenter" means the center of the smallest sphere through which the beam axis passes when the equipment moves through a full range of rotations about its common center.

"Kerma" means the quantity defined by the International Commission on Radiation Units and Measurements. The kerma, K, is the quotient of dEtr by dm, where dEtr is the sum of the initial kinetic energies of all the charged participles liberated by uncharged particles in a mass dm of material; thus K=dEtr/dm, in units of J/kg, where the special name for the unit of kerma is gray (Gy). When the material is air, the quantity is referred to as “air kerma.”

"Kilovolts peak" (See "Peak tube potential").

"kV" means kilovolts.

"kVp" (See "Peak tube potential").

"kWs" means kilowatt second.

"Last image hold (LIH) radiograph" means an image obtained either by retaining one or more fluoroscopic images, which may be temporarily integrated, at the end of a fluoroscopic exposure or by initiating a separate and distinct radiographic exposure automatically and immediately in conjunction with termination of the fluoroscopic exposure.

"Lateral fluoroscope" means the x-ray tube and image receptor combination in a biplane system dedicated to the lateral projection. It consists of the lateral x-ray tube housing assembly and the lateral image receptor that are fixed in position relative to the table with the x-ray beam axis parallel to the plane of the table.

"Lead equivalent" means the thickness of lead affording the same attenuation, under specified conditions, as the material in question.

"Leakage radiation" means radiation emanating from the diagnostic source assembly except for:

(1) The useful beam; and

(2) Radiation produced when the exposure switch or timer is not activated.

"Leakage technique factors" means the technique factors associated with the diagnostic source assembly which are used in measuring leakage radiation. They are defined as follows:

(1) For diagnostic source assemblies intended for capacitor energy storage equipment, the maximum-rated peak tube potential and the maximum-rated number of exposures in an hour for operation at the maximum-rated peak tube potential with the quantity of charge per exposure being 10 millicoulombs (or 10 mAs) or the minimum obtainable from the unit, whichever is larger;

(2) For diagnostic source assemblies intended for field emission equipment rated for pulsed operation, the maximum-rated peak tube potential and the maximum-rated number of x-ray pulses in an hour for operation at the maximum-rated peak tube potential;

(3) For all other diagnostic source assemblies, the maximum-rated peak tube potential and the maximum-rated continuous tube current for the maximum-rated peak tube potential.

"Licensed Practitioner" means an individual licensed to practice medicine, dentistry, dental hygiene, podiatry, chiropractic, or osteopathy in this State.

"Light field" means that area of the intersection of the light beam from the beam-limiting device and one of the set of planes parallel to and including the plane of the image receptor, whose perimeter is the locus of points at which the illumination is one-fourth of the maximum in the intersection.

"Line-voltage regulation" means the difference between the no-load and the load line potentials expressed as a percent of the load line potential , as follows:

Percent line-voltage regulation = 100 (Vn-Vl)/Vl

where:

Vn = No-load line potential; and

Vl = Load line potential.

"mA" means milliampere.

“mAs" means milliampere second.

"Mobile x-ray equipment" (See "X-ray equipment").

"Mode of operation" means, for fluoroscopic systems, a distinct method of fluoroscopy or radiography provided by the manufacturer and selected with a set of several technique factors or other control settings uniquely associated with the mode. The set of distinct technique factors and control settings for the mode may be selected by the operation of a single control. Examples of distinct modes of operation include normal fluoroscopy (analog or digital), high-level control fluoroscopy, cineradiography (analog and digital), digital subtraction angiography, electronic radiography using the fluoroscopic image receptor, and photospot recording. In a specific mode of operation, certain system variables affecting kerma, AKR, or image quality, such as image magnification, x-ray field size, pulse rate, pulse duration, number of pulses, source-image receptor distance (SID), or optical aperture, may be adjustable or may vary; their variation per se does not comprise a mode of operation different from the one that has been selected.

"Movable tabletop" means a tabletop which, when assembled for use, is capable of movement with respect to its supporting structure within the plane of the tabletop.

"Non-image-intensified fluoroscopy" means fluoroscopy using only a fluorescent screen.

"Patient" means an individual or animal subjected to healing arts examination, diagnosis or treatment.

"PBL" See "Positive beam limitation."

"Peak tube potential" means the maximum value of the potential difference across the x-ray tube during an exposure.

"Phantom" means a volume of material behaving in a manner similar to tissue with respect to the attenuation and scattering of radiation. This requires that both the atomic number (Z) and the density of the material be similar to that of tissue.

"PID" (See "Position indicating device").

"Portable x-ray equipment" (See "X-ray equipment").

"Position indicating device" means a device on dental x-ray equipment used to indicate the beam position and to establish a definite source-surface (skin) distance. It may or may not incorporate or serve as a beam-limiting device.

"Positive beam limitation" means the automatic or semi-automatic adjustment of an x-ray beam to the size of the selected image receptor, whereby exposures cannot be made without such adjustment.

"Primary protective barrier" means the material, excluding filters, placed in the useful beam to reduce the radiation exposure [beyond the patient and cassette holder] for protection purposes.

"Protective apron" means an apron made of radiation absorbing materials used to reduce radiation exposure.

"Protective glove" means a glove made of radiation absorbing materials used to reduce radiation exposure.

"Pulsed mode" means operation of the x-ray system such that the x-ray tube current is pulsed by the x-ray control to produce one or more exposure intervals of duration less than one-half second.

“Qualified expert” means an individual who has demonstrated to the satisfaction of the Agency that such individual possesses the knowledge and training to measure ionizing radiation, to evaluate safety techniques, and to advise regarding radiation protection needs, for example, individuals certified in the appropriate field by the American Board of Radiology, or the American Board of Health Physics, or the American Board of Medical Physics, or those having equivalent qualifications. With reference to the calibration of radiation therapy equipment, an individual, in addition to the above qualifications, must be qualified in accordance with Part X.

"Qualified medical physicist" means an individual who meets the requirements specified in Part X.

"Quick change x-ray tube" means an x-ray tube designed for use in its associated tube housing such that:

(1) The tube cannot be inserted in its housing in a manner that would result in noncompliance of the system with the requirements of 6.0;

(2) The focal spot position will not cause noncompliance with the provisions of this section or;

(3) The shielding within the tube housing cannot be displaced; and

(4) Any removal and subsequent replacement of a beam-limiting device during reloading of the tube in the tube housing will not result in noncompliance of the x-ray system with the applicable field limitation and alignment requirements of 6.0.

"Radiation detector" means a device which in the presence of radiation provides a signal or other indication suitable for use in measuring one or more quantities of incident radiation.

"Radiation therapy simulation system" means a radiographic or fluoroscopic x‑ray system intended for localizing the volume to be exposed during radiation therapy and confirming the position and size of the therapeutic irradiation field.

"Radiograph" means an image receptor on which the image is created directly or indirectly by an x-ray pattern and results in a permanent record.

"Radiography" means a technique for generating and recording an x-ray pattern for the purpose of providing the user with an image(s) after termination of the exposure.

"Rated line voltage" means the range of potentials, in volts, of the supply line specified by the manufacturer at which the x-ray machine is designed to operate.

"Rated output current" means the maximum allowable load current of the x-ray high-voltage generator.

"Rating" means the operating limits specified by the manufacturer.

"Recording" means producing a retrievable form of an image resulting from x-ray photons.

"Scan" means the complete process of collecting x-ray transmission data for the production of a tomogram. Data may be collected simultaneously during a single scan for the production of one or more tomograms.

"Scan time" means the period of time between the beginning and end of x-ray transmission data accumulation for a single scan.

"Scattered radiation" means radiation that, during passage through matter, has been deviated in direction (See "Direct scattered radiation").

"Shutter" means a device attached to the tube housing assembly which can intercept the entire cross sectional area of the useful beam and which has a lead equivalency not less than that of the tube housing assembly.

"SID" (See "Source-image receptor distance").

"Solid state x-ray imaging device" means an assembly, typically in a rectangular panel configuration, that intercepts x-ray photons and converts the photon energy into a modulated electronic signal representative of the x-ray intensity over the area of the imaging device. The electronic signal is then used to create an image for display and/or storage.

"Source" means the focal spot of the x-ray tube.

"Source-image receptor distance" means the distance from the source to the center of the input surface of the image receptor.

"Source-skin distance (SSD)" means the distance from the source to the center of the entrant x-ray field in the plane tangent to the patient skin surface.

"Spot film" means a radiograph which is made during a fluoroscopic examination to permanently record conditions which exist during that fluoroscopic procedure.

"Spot-film device" means a device intended to transport and/or position a radiographic image receptor between the x-ray source and fluoroscopic image receptor. It includes a device intended to hold a cassette over the input end of the fluoroscopic image receptor for the purpose of producing a radiograph.

"Stationary tabletop" means a tabletop which, when assembled for use, is incapable of movement with respect to its supporting structure within the plane of the tabletop.

"Stationary x-ray equipment" (See "X-ray equipment").

"Stray radiation" means the sum of leakage and scattered radiation.

"Technique factors" means the following conditions of operation:

(1) For capacitor energy storage equipment, peak tube potential in kilovolts (kV) and quantity of charge in milliampere-seconds (mAs);

(2) For field emission equipment rated for pulsed operation, peak tube potential in kV, and number of x-ray pulses;

(3) For CT equipment designed for pulsed operation, peak tube potential in kV, scan time in seconds, and either tube current in milliamperes (mA), x-ray pulse width in seconds, and the number of x-ray pulses per scan, or the product of tube current, x-ray pulse width, and the number of x-ray pulses in mAs;

(4) For CT equipment not designed for pulsed operation, peak tube potential in kV, and either tube current in mA and scan time in seconds, or the product of tube current and exposure time in mAs and the scan time when the scan time and exposure time are equivalent; and

(5) For all other equipment, peak tube potential in kV, and either tube current in mA and exposure time in seconds, or the product of tube current and exposure time in mAs.

"Tomogram" means the depiction of the x-ray attenuation properties of a section through the body.

"Tube" means an x-ray tube, unless otherwise specified.

"Tube housing assembly" means the tube housing with tube installed. It includes high-voltage and/or filament transformers and other appropriate elements when such are contained within the tube housing.

"Tube rating chart" means the set of curves which specify the rated limits of operation of the tube in terms of the technique factors.

"Useful beam" means the radiation which passes through the tube housing port and the aperture of the beam limiting device when the exposure switch or timer is activated.

"Variable-aperture beam-limiting device" means a beam-limiting device which has capacity for stepless adjustment of the x-ray field size at a given SID.

"Visible area" means that portion of the input surface of the image receptor over which incident x-ray photons are producing a visible image.

"X-ray control" means a device which controls input power to the x-ray high-voltage generator and/or the x-ray tube. It includes equipment such as timers, phototimers, automatic brightness stabilizers, and similar devices, which control the technique factors of an x-ray exposure.

"X-ray exposure control" means a device, switch, button or other similar means by which an operator initiates and/or terminates the radiation exposure. The x-ray exposure control may include such associated equipment as timers and back-up timers.

"X-ray equipment" means an x-ray system, subsystem, or component thereof. Types of x-ray equipment are as follows:

(1) "Mobile x-ray equipment" means x-ray equipment mounted on a permanent base with wheels and/or casters for moving while completely assembled.

(2) "Portable x-ray equipment" means x-ray equipment designed to be hand-carried.

(3) "Stationary x-ray equipment" means x-ray equipment which is installed in a fixed location.

"X-ray field" means that area of the intersection of the useful beam and any one of a set of planes parallel to and including the plane of the image receptor, whose perimeter is the locus of points at which the AKR is one-fourth of the maximum in the intersection.

"X-ray high-voltage generator" means a device which transforms electrical energy from the potential supplied by the x-ray control to the tube operating potential. The device may also include means for transforming alternating current to direct current, filament transformers for the x-ray tube(s), high-voltage switches, electrical protective devices, and other appropriate elements.

"X-ray subsystem" means any combination of two or more components of an x-ray system for which there are requirements specified in this section and 4.0, 5.0, 6.0.

"X-ray system" means an assemblage of components for the controlled production of x-rays. It includes minimally an x-ray high-voltage generator, an x-ray control, a tube housing assembly, a beam-limiting device, and the necessary supporting structures. Additional components which function with the system are considered integral parts of the system.

"X-ray table" means a patient support device with its patient support structure (tabletop) interposed between the patient and the image receptor during radiography and/or fluoroscopy. This includes, but is not limited to, any stretcher equipped with a radiolucent panel and any table equipped with a cassette tray (or bucky), cassette tunnel, fluoroscopic image receptor, or spot-film device beneath the tabletop.

"X-ray tube" means any electron tube which is designed for the conversion of electrical energy into x-ray energy.

3.1 Radiation Safety Requirements. The registrant, licensee, shall be responsible for directing the operation of the x-ray system(s) under his administrative control. The registrant, licensee, or the registrant's, licensee’s, agent shall assure that the requirements of these regulations are met in the operation of the x-ray system(s).

3.1.1 An x-ray system which does not meet the provisions of these regulations shall not be operated for diagnostic purposes.

3.1.2 Individuals who will be operating the x-ray systems shall meet the Agency’s qualifications to conduct the practice of radiologic technology.

3.1.3 A chart shall be provided in the vicinity of the diagnostic x-ray system's control panel which specifies, for all examinations performed with that system, the following information:

3.1.3.1 Patient's body part and anatomical size, or body part thickness, or age (for pediatrics), versus technique factors to be utilized;

3.1.3.2 Type and size of the image receptor to be used;

3.1.3.3 Type and size of the image receptor combination to be used, if any;

3.1.3.4 Source to image receptor distance to be used (except for dental intraoral radiography);

3.1.3.5 Type and location of placement of patient shielding (e.g., gonad, etc.) to be used; and

3.1.3.6 For mammography, indication of kVp/target/filter combination.

3.1.4 The registrant [licensee] of a facility shall create and make available to x-ray operators written safety procedures, including patient holding and any restrictions of the operating technique required for the safe operation of the particular x-ray system. The operator shall be able to demonstrate familiarity with these procedures.

3.1.5 Except for patients who cannot be moved out of the room, only the staff, ancillary personnel or other persons required for the medical procedure or training shall be in the room during the radiographic exposure. Other than the patient being examined:

3.1.5.1 All individuals shall be positioned such that no part of the body will be struck by the useful beam unless protected by not less than 0.5 millimeter lead equivalent material;

3.1.5.2 The x-ray operator, other staff, ancillary personnel, and other persons required for the medical procedure shall be protected from the direct scatter radiation by protective aprons or whole body protective barriers of not less than 0.25 millimeter lead equivalent material;

3.1.5.3 Human patients who cannot be removed from the room shall be protected from the direct scatter radiation by whole body protective barriers of not less than 0.25 millimeter lead equivalent material or shall be so positioned that the nearest portion of the body is at least 2 meters from both the tube head and the nearest edge of the image receptor.

3.1.6 Gonad shielding of not less than 0.5 millimeter lead equivalent material shall be used for human patients, who have not passed the reproductive age, during radiographic procedures in which the gonads are in the useful beam, except for cases in which this would interfere with the diagnostic procedure.

3.1.7 Individuals shall not be exposed to the useful beam except for healing arts purposes and unless such exposure has been authorized by a licensed practitioner of the healing arts. This provision specifically prohibits deliberate exposure for the following purposes:

3.1.7.1 Exposure of an individual for training, demonstration, or other non-healing arts purposes; and

3.1.7.2 Exposure of an individual for the purpose of healing arts screening except as authorized by 3.1.11.

3.1.8 When a patient or image receptor must be provided with auxiliary support during a radiation exposure:

3.1.8.1 Mechanical holding devices shall be used when the technique permits. The written safety procedures, required by 3.1.4, shall list individual projections where holding devices cannot be utilized;

3.1.8.2 Written safety procedures, as required by 3.1.4, shall indicate the requirements for selecting a holder and the procedure the holder shall follow;

3.1.8.3 The human holder shall be instructed in personal radiation safety and protected as required by 3.1.5.;

3.1.8.4 No individual shall be used routinely to hold image receptor or patients;

3.1.8.5 In those cases where the patient must hold the image receptor, except during intraoral examinations, any portion of the body other than the area of clinical interest struck by the useful beam shall be protected by not less than 0.5 millimeter lead equivalent material; and

3.1.8.6 Each facility shall have leaded aprons and gloves available in sufficient numbers to provide protection for all personnel who are involved with x-ray operations and who are otherwise not shielded.

3.1.9 Procedures and auxiliary equipment designed to minimize patient and personnel exposure commensurate with the needed diagnostic information shall be utilized.

3.1.9.1 The fastest imaging system consistent with the diagnostic objective of the examinations shall be used. Film cassettes without intensifying screens shall not be used for any routine diagnostic radiological imaging, with the exception of veterinary radiography and standard film packets for intraoral use in dental radiography.

3.1.9.2 The radiation exposure to the patient shall be the minimum exposure required to produce images of good diagnostic quality.

3.1.9.3 Portable or mobile x-ray equipment shall be used only for examinations where it is impractical to transfer the patient(s) to a stationary x-ray installation. The use of hand held devices must be approved by the Agency utilizing the criteria in Appendix B.

3.1.9.4 X-ray systems subject to 6.0 shall not be utilized in procedures where the source to patient distance is less than 30 centimeters, except for veterinary systems.

3.1.9.5 If grids are used between the patient and the image receptor to decrease scatter to the film and improve contrast, the grid shall:

3.1.9.5.1 Be positioned properly, i.e., tube side facing the right direction, and grid centered to the central ray;

3.1.9.5.2 If the grid is of the focused type, be of the proper focal distance for the SIDs being used.

3.1.10 All individuals who are associated with the operation of an x-ray system are subject to the requirements of D.1201, D.1207 and D.1208 of these regulations.

3.1.11 Healing Arts Screening. Any person proposing to conduct a healing arts screening program shall not initiate such a program without prior approval of the Agency. When requesting such approval, that person shall submit the information outlined in Appendix A of this Part. If any information submitted to the Agency becomes invalid or outdated, the Agency shall be immediately notified.

3.1.12 Information and Maintenance Record and Associated Information. The registrant [licensee] shall maintain the following information for each x-ray system for inspection by the Agency:

3.1.12.1 Model and serial numbers of all major components, and user's manuals for those components;

3.1.12.2 Tube rating charts and cooling curves;

3.1.12.3 Records of surveys, calibrations, maintenance, and modifications performed on the x-ray system(s); and

3.1.12.4 A copy of all correspondence with this Agency regarding that x-ray system.

3.1.13 X-Ray Utilization Record. Except for veterinary facilities, each facility shall maintain a record containing the patient's name, the type of examinations, and the dates the examinations were performed. When the patient or film must be provided with human auxiliary support, the name of the human holder should be recorded.

3.2 X-Ray Film Processing Facilities and Practices.

3.2.1 Each installation using a radiographic x-ray system and using analog image receptors (e.g. radiographic film) shall have available suitable equipment for handling and processing radiographic film in accordance with the following provisions:

3.2.1.1 Manually developed film:

3.2.1.2 Processing tanks shall be constructed of mechanically rigid, corrosion resistant material; and

3.2.1.3 The temperature of solutions in the tanks shall be maintained within the range of 60o F to 80o F (16o C to 27o C). Film shall be developed in accordance with the time-temperature relationships recommended by the film manufacturer, or, in the absence of such recommendations, with the following time-temperature chart:

Time-Temperature Chart | ||

Thermometer Reading (Degrees) | Minimum Developing Time (Minutes) | |

oC | oF | |

26.7 | 80 | 2 |

26.1 | 79 | 2 |

25.6 | 78 | 2½ |

25.0 | 77 | 2½ |

24.4 | 76 | 3 |

23.9 | 75 | 3 |

23.3 | 74 | 3½ |

22.8 | 73 | 3½ |

22.2 | 72 | 4 |

21.7 | 71 | 4 |

21.1 | 70 | 4½ |

20.6 | 69 | 4½ |

20.0 | 68 | 5 |

19.4 | 67 | 5½ |

18.9 | 66 | 5½ |

18.3 | 65 | 6 |

17.8 | 64 | 6½ |

17.2 | 63 | 7 |

16.7 | 62 | 8 |

16.1 | 61 | 8½ |

15.6 | 60 | ½ |

3.2.1.4 Devices shall be utilized which will indicate the actual temperature of the developer and signal the passage of a preset time appropriate to the developing time required.

3.2.1.5 Automatic processors and other closed processing systems: Films shall be developed in accordance with the time-temperature relationships recommended by the film manufacturer; in the absence of such recommendations, the film shall be developed using the following chart:

Developer Temperature | Minimum Immersion Timea/ | |

oC | oF | Seconds |

35.5 | 96 | 19 |

35 | 95 | 20 |

34.5 | 94 | 21 |

34 | 93 | 22 |

33.5 | 92 | 23 |

33 | 91 | 24 |

32 | 90 | 25 |

31.5 | 89 | 26 |

31 | 88 | 27 |

30.5 | 87 | 28 |

30 | 86 | 29 |

29.5 | 85 | 30 |

a/ Immersion time only, no crossover time included. | ||

3.2.1.6 Processing deviations from the requirements of 3.2.1 shall be documented by the registrant [licensee] in such manner that the requirements are shown to be met or exceeded (e.g., extended processing, and special rapid chemistry).

3.3 Other Requirements.

3.3.1 Pass boxes, if provided, shall be so constructed as to exclude light from the darkroom when cassettes are placed in or removed from the boxes, and shall incorporate adequate shielding from stray radiation to prevent exposure of undeveloped film.

3.3.2 The darkroom shall be light tight and use proper safelighting such that any film type in use exposed in a cassette to x-radiation sufficient to produce an optical density from 1 to 2 when processed shall not suffer an increase in density greater than 0.1 (0.05 for mammography) when exposed in the darkroom for 2 minutes with all safelights on. If used, daylight film handling boxes shall preclude fogging of the film.

3.3.3 Darkrooms typically used by more than one individual shall be provided a method to prevent accidental entry while undeveloped films are being handled or processed.

3.3.4 Film shall be stored in a cool, dry place and shall be protected from exposure to stray radiation. Film in open packages shall be stored in a light tight container.

3.3.5 Film cassettes and intensifying screens shall be inspected periodically and shall be cleaned and replaced as necessary to best assure radiographs of good diagnostic quality.

3.3.6 Outdated x-ray film shall not be used for diagnostic radiographs, unless the film has been stored in accordance with the manufacturer's recommendations and a sample of the film passes a sensitometric test for normal ranges of base plus fog and speed.

3.3.7 Film developing solutions shall be prepared in accordance with the directions given by the manufacturer, and shall be maintained in strength by replenishment or renewal so that full development is accomplished within the time specified by the manufacturer.

In addition to other requirements of this Part, all diagnostic x‑ray systems shall meet the following requirements:

4.1 Warning Label. The control panel containing the main power switch shall bear the warning statement, legible and accessible to view: "WARNING: This x-ray unit may be dangerous to patient and operator unless safe exposure factors, operating instructions and maintenance schedules are observed."

4.2 Leakage Radiation from the Diagnostic Source Assembly. The leakage radiation from the diagnostic source assembly measured at a distance of 1 meter in any direction from the source shall not exceed 0.88 milligray (mGy) air kerma (vice 100 milliroentgen (mR) exposure) in 1 hour when the x-ray tube is operated at its leakage technique factors. If the maximum rated peak tube potential of the tube housing assembly is greater than the maximum rated peak tube potential for the diagnostic source assembly, positive means shall be provided to limit the maximum x-ray tube potential to that of the diagnostic source assembly. Compliance shall be determined by measurements averaged over an area of 100 square centimeters with no linear dimension greater than 20 centimeters.

4.3 Radiation from Components Other Than the Diagnostic Source Assembly. The radiation emitted by a component other than the diagnostic source assembly shall not exceed an air kerma of 18 microgray (vice 2 milliroentgens exposure) in 1 hour at 5 centimeters from any accessible surface of the component when it is operated in an assembled x-ray system under any conditions for which it was designed. Compliance shall be determined by measurements averaged over an area of 100 square centimeters with no linear dimension greater than 20 centimeters.

4.4 Beam Quality.

4.4.1 Half-Value Layer (HVL).

4.4.1.1 The HVL of the useful beam for a given x-ray tube potential shall not be less than the values shown in Table 1 in this section under the heading “Specified Dental Systems,” for any dental x-ray system designed for use with intraoral image receptors and manufactured after December 1, 1980; under the heading, “I-Other X-Ray Systems,” for any dental x-ray system designed for use with intraoral image receptors and manufactured before or on December 1, 1980, and all other x-ray systems subject to this section and manufactured before June 10, 2006; and under the heading, “II-Other X-Ray Systems,” for all x-ray systems, except dental x-ray systems designed for use with intraoral image receptors, subject to this section and manufactured on or after June 10, 2006. If it is necessary to determine such half-value layer at an x-ray tube potential which is not listed in Table 1 of this section, linear interpolation or extrapolation may be made. Positive means shall be provided to ensure that at least the minimum filtration needed to achieve beam quality requirements is in the useful beam during each exposure. In the case of a system, which is to be operated with more than one thickness of filtration, this requirement can be met by a filter interlocked with the kilovoltage selector which will prevent x-ray emissions if the minimum required filtration is not in place.

X-Ray Tube Voltage (kilovolt peak) | ||||

Design Operating Range | Measured Operating Potential | Minimum HVL (mm in Aluminum) | ||

Specified Dental Systems \1\ | Other X-Ray Systems\2\ | Other X-Ray Systems\3\ | ||

Below 51 | 30 | 1.5 | 0.3 | 0.3 |

40 | 1.5 | 0.4 | 0.4 | |

50 | 1.5 | 0.5 | 0.5 | |

51 to 70 | 51 | 1.5 | 1.2 | 1.3 |

60 | 1.5 | 1.3 | 1.5 | |

70 | 1.5 | 1.5 | 1.8 | |

Above 70 | 71 | 2.1 | 2.1 | 2.5 |

80 | 2.3 | 2.3 | 2.9 | |

90 | 2.5 | 2.5 | 3.2 | |

100 | 2.7 | 2.7 | 3.6 | |

110 | 3.0 | 3.0 | 3.9 | |

120 | 3.2 | 3.2 | 4.3 | |

130 | 3.5 | 3.5 | 4.7 | |

140 | 3.8 | 3.8 | 5.0 | |

150 | 4.1 | 4.1 | 5.4 | |

\1\ Dental x-ray systems designed for use with intraoral image receptors and manufactured after December 1, 1980. \2\ Dental x-ray systems designed for use with intraoral image receptors and manufactured before or on December 1, 1980, and all other x-ray systems subject to this section and manufactured before June 10, 2006. \3\ All x-ray systems, except dental x-ray systems designed for use with intraoral image receptors, subject to this section and manufactured on or after June 10, 2006. | ||||

4.4.1.2 Optional filtration. Fluoroscopic systems manufactured on or after June 10, 2006, incorporating an x-ray tube(s) with a continuous output of 1 kilowatt or more and an anode heat storage capacity of 1 million heat units or more shall provide the option of adding x-ray filtration to the diagnostic source assembly in addition to the amount needed to meet the half-value layer provisions of this subsection. The selection of this additional x-ray filtration shall be either at the option of the user or automatic as part of the selected mode of operation. A means of indicating which combination of additional filtration is in the x-ray beam shall be provided.

4.4.1.3 Measuring compliance. For capacitor energy storage equipment, compliance shall be determined with the maximum selectable quantity of charge per exposure.

4.4.1.4 Aluminum equivalent of material between patient and image receptor. Except when used in a CT x-ray system, the aluminum equivalent of each of the items listed in Table 2 in this paragraph, which are used between the patient and the image receptor, may not exceed the indicated limits. Compliance shall be determined by x-ray measurements made at a potential of 100 kilovolts peak and with an x-ray beam that has an HVL specified in Table 1 of this section for the potential. This requirement applies to front panel(s) of cassette holders and film changers provided by the manufacturer for patient support or for prevention of foreign object intrusions. It does not apply to screens and their associated mechanical support panels or grids. Table 2 follows:

Item | Maximum Aluminum Equivalent (millimeters) |

Front panel(s) of cassette holders (total of all) Film panel(s) of film changer (total of all) Cradle Tabletop, stationary, without articulated joints Tabletop, movable, without articulated joint(s) (including stationary subtop) Tabletop, with radiolucent panel having one articulated joint Tabletop, with radiolucent panel having two or more articulated joints Tabletop, cantilevered Tabletop, radiation therapy simulator | 1.2 1.2 2.3 1.2 1.7 1.7 2.3 2.3 5.0 |

4.5 Battery charge indicator. On battery-powered generators, visual means shall be provided on the control panel to indicate whether the battery is in a state of charge adequate for proper operation.

4.6 Modification of certified diagnostic x-ray components and systems.

4.7 Diagnostic x-ray components and systems certified in accordance with 21 CFR Part 1020 shall not be modified such that the component or system fails to comply with any applicable provision of this Part.

4.8 The owner of a diagnostic x-ray system who uses the system in a professional or commercial capacity may modify the system provided the modification does not result in the failure of the system or component to comply with the applicable requirements of this Part. The owner who causes such modification need not submit the reports required by this Part, provided the owner records the date and the details of the modification in the system records and maintains this information, and provided the modification of the x-ray system does not result in a failure to comply with this Part. Such system modifications should be per suggested manufacturer’s specifications.

4.9 Multiple Tubes. Where two or more radiographic tubes are controlled by one exposure switch, the tube or tubes which have been selected shall be clearly indicated prior to initiation of the exposure. This indication shall be both on the x-ray control panel and at or near the tube housing assembly which has been selected.

4.10 Mechanical Support of Tube Head. The tube housing assembly supports shall be adjusted such that the tube housing assembly will remain stable during an exposure unless tube housing movement is a designed function of the x-ray system.

4.11 Technique Indicators.

4.11.1 For x-ray equipment capable of displaying technique factors, the technique factors to be used during an exposure shall be indicated before the exposure begins. If automatic exposure controls are used, the technique factors which are set prior to the exposure shall be indicated.

4.11.2 The requirement of 4.11.1 may be met by permanent markings on equipment having fixed technique factors. Indication of technique factors shall be visible from the operator's position except in the case of spot films made by the fluoroscopist.

4.12 Maintaining Compliance. Diagnostic x-ray systems and their associated components used on humans and certified pursuant to the Federal X-Ray Equipment Performance Standard (21 CFR Part 1020) shall be maintained in compliance with applicable requirements of that standard.

4.13 Locks. All position locking, holding, and centering devices on x-ray system components and systems shall function as intended.

The provisions of this Part apply to equipment for fluoroscopic imaging or for recording images from the fluoroscopic image receptor, except computed tomography x-ray systems manufactured on or after November 29, 1984.

5.1 Primary Protective Barrier.

5.1.1 Limitation of useful beam. The fluoroscopic imaging assembly shall be provided with a primary protective barrier which intercepts the entire cross section of the useful beam at any SID. The x-ray tube used for fluoroscopy shall not produce x-rays unless the barrier is in position to intercept the entire useful beam. The AKR due to transmission through the barrier with the attenuation block in the useful beam combined with radiation from the fluoroscopic imaging receptor shall not exceed 3.34x10-3 percent of the entrance AKR, at a distance of 10 cm from any accessible surface of the fluoroscopic imaging assembly beyond the plane of the image receptor. Radiation therapy simulation systems shall be exempt from this requirement provided the systems are intended only for remote control operation.

5.1.2 Measuring compliance. The AKR shall be measured in accordance with 5.3.2. The AKR due to transmission through the primary barrier combined with radiation from the fluoroscopic image receptor shall be determined by measurements averaged over an area of 100 square cm with no linear dimension greater than 20 cm. If the source is below the tabletop, the measurement shall be made with the input surface of the fluoroscopic imaging assembly positioned 30 cm above the tabletop. If the source is above the tabletop and the SID is variable, the measurement shall be made with the end of the beam-limiting device or spacer as close to the tabletop as it can be placed, provided that it shall not be closer than 30 cm. Movable grids and compression devices shall be removed from the useful beam during the measurement. For all measurements, the attenuation block shall be positioned in the useful beam 10 cm from the point of measurement of entrance AKR and between this point and the input surface of the fluoroscopic imaging assembly.

5.2 Field Limitation.

5.2.1 Angulation. For fluoroscopic equipment manufactured after February 25, 1978, when the angle between the image receptor and the beam axis of the x-ray beam is variable, means shall be provided to indicate when the axis of the x-ray beam is perpendicular to the plane of the image receptor. Compliance with 5.2.4 and 5.2.5 shall be determined with the beam axis indicated to be perpendicular to the plane of the image receptor.

5.2.2 Further means for limitation. Means shall be provided to permit further limitation of the x-ray field to sizes smaller than the limits of 5.2.4 and 5.2.5. Beam-limiting devices manufactured after May 22, 1979, and incorporated in equipment with a variable SID and/or capability of a visible area of greater than 300 square cm, shall be provided with means for stepless adjustment of the x-ray field. Equipment with a fixed SID and the capability of a visible area of no greater than 300 square cm shall be provided with either stepless adjustment of the x-ray field or with a means to further limit the x-ray field size at the plane of the image receptor to 125 square cm or less. Stepless adjustment shall, at the greatest SID, provide continuous field sizes from the maximum obtainable to a field size containable in a square of 5 cm by 5 cm. This paragraph does not apply to non-image-intensified fluoroscopy.

5.2.3 Non-image-intensified fluoroscopy. The x-ray field produced by non-image-intensified fluoroscopic equipment shall not extend beyond the entire visible area of the image receptor. Means shall be provided for stepless adjustment of field size. The minimum field size, at the greatest SID, shall be containable in a square of 5 cm by 5 cm.

5.2.4 Fluoroscopy and radiography using the fluoroscopic imaging assembly with inherently circular image receptors.

5.2.4.1 For fluoroscopic equipment manufactured before June 10, 2006, other than radiation therapy simulation systems, the following applies:

5.2.4.1.1 Neither the length nor width of the x-ray field in the plane of the image receptor shall exceed that of the visible area of the image receptor by more than 3 percent of the SID. The sum of the excess length and the excess width shall be no greater than 4 percent of the SID.

5.2.4.1.2 For rectangular x-ray fields used with circular image receptors, the error in alignment shall be determined along the length and width dimensions of the x-ray field which pass through the center of the visible area of the image receptor.

5.2.4.2 For fluoroscopic equipment manufactured on or after June 10, 2006, other than radiation simulation systems, the maximum area of the x-ray field in the plane of the image receptor shall conform with one of the following requirements:

5.2.4.2.1 When any linear dimension of the visible area of the image receptor measured through the center of the visible area is less than or equal to 34 cm in any direction, at least 80 percent of the area of the x-ray field overlaps the visible area of the image receptor, or

5.2.4.2.2 When any linear dimension of the visible area of the image receptor measured through the center of the visible area is greater than 34 cm in any direction, the x-ray field measured along the direction of greatest misalignment with the visible area of the image receptor does not extend beyond the edge of the visible area of the image receptor by more than 2 cm.

5.2.5 Fluoroscopy and radiography using fluoroscopic imaging assembly with inherently rectangular image receptors. For x-ray systems manufactured on or after June 10, 2006, the following applies:

5.2.5.1 Neither the length nor width of the x-ray field in the plane of the image receptor shall exceed that of the visible area of the image receptor by more than 3 percent of the SID. The sum of the excess length and the excess width shall be no greater than 4 percent of the SID.

5.2.5.2 The error in alignment shall be determined along the length and width dimensions of the x-ray field which pass through the center of the visible area of the image receptor.

5.3 If the fluoroscopic x-ray field size is adjusted automatically as the SID or image receptor size is changed, a capability may be provided for overriding the automatic adjustment in case of system failure. If it is so provided, a signal visible at the fluoroscopist’s position shall indicate whenever the automatic field adjustment is overridden. Each such system failure override switch shall be clearly labeled as follows:

FOR X-RAY FIELD LIMITATION SYSTEM FAILURE

5.3.1 Activation of Tube. X-ray production in the fluoroscopic mode shall be controlled by a device which requires continuous pressure by the operator for the entire time of any exposure. When recording serial radiographic images from the fluoroscopic image receptor, the operator shall be able to terminate the x-ray exposure(s) at any time, but means may be provided to permit completion of any single exposure of the series in process.

5.3.2 Air Kerma Rates. For fluoroscopic equipment, the following requirements apply:

5.4 Fluoroscopic equipment manufactured before May 19, 1995.

5.4.1 Equipment provided with automatic exposure rate control (AERC) shall not be operable at any combination of tube potential and current that will result in an AKR in excess of 88 mGy per minute (vice 10 R/min exposure rate) at the measurement point specified in 5.7, except as specified in 5.5.1.

5.4.2 Equipment provided without AERC shall not be operable at any combination of tube potential and current that will result in an AKR in excess of 44 mGy per minute (vice 5 R/min exposure rate) at the measurement point specified in 5.7, except as specified in 5.5.1.

5.4.3 Equipment provided with both an AERC mode and a manual mode shall not be operable at any combination of tube potential and current that will result in an AKR in excess of 88 mGy per minute (vice 10 R/min exposure rate) in either mode at the measurement point specified in 5.7, except as specified in 5.5.1.

5.4.4 Equipment may be modified in accordance with this Part to comply with 5.6. When the equipment is modified, it shall bear a label indicating the date of the modification and the statement:

5.4.4.1 Exceptions:

5.4.4.1.1 During recording of fluoroscopic images, or

5.4.4.1.2 When a mode of operation has an optional high-level control, in which case that mode shall not be operable at any combination of tube potential and current that will result in an AKR in excess of the rates specified in paragraphs (1), (2) and (3) at the measurement point specified in 5.7, unless the high-level control is activated. Special means of activation of high-level controls shall be required. The high-level control shall be operable only when continuous manual activation is provided by the operator. A continuous signal audible to the fluoroscopist shall indicate that the high-level control is being employed.

5.5 Fluoroscopic equipment manufactured on or after May 19, 1995.

5.5.1 Shall be equipped with AERC if operable at any combination of tube potential and current that results in an AKR greater than 44 mGy per minute (vice 5 R/min exposure rate) at the measurement point specified in 5.7. Provision for manual selection of technique factors may be provided.

5.5.2 Shall not be operable at any combination of tube potential and current that will result in an AKR in excess of 88 mGy per minute (vice 10 R/min exposure rate) at the measurement point specified in 5.7, except as specified in 5.6.3.

5.5.3 Exceptions:

5.5.3.1 For equipment manufactured prior to June 10, 2006, during the recording of images from a fluoroscopic image receptor using photographic film or a video camera when the x-ray source is operated in a pulsed mode.

5.5.3.2 For equipment manufactured on or after June 10, 2006, during the recording of images from the fluoroscopic image receptor for the purpose of providing the user with a recorded image(s) after termination of the exposure. Such recording does not include images resulting from a last-image-hold feature that are not recorded.

5.5.3.3 When a mode of operation has an optional high-level control and the control is activated, in which case the equipment shall not be operable at any combination of tube potential and current that will result in an AKR in excess of 176 mGy per minute (vice 20 R/min exposure rate) at the measurement point specified in 5.7. Special means of activation of high-level controls shall be required. The high-level control shall be operable only when continuous manual activation is provided by the operator. A continuous signal audible to the fluoroscopist shall indicate that the high-level control is employed.

5.6 Measuring compliance. Compliance with this subsection shall be determined as follows:

5.6.1 If the source is below the x-ray table, the AKR shall be measured at 1 cm above the tabletop or cradle.

5.6.2 If the source is above the x-ray table, the AKR shall be measured at 30 cm above the tabletop with the end of the beam-limiting device or spacer positioned as closely as possible to the point of measurement.

5.6.3 In a C-arm type of fluoroscope, the AKR shall be measured at 30 cm from the input surface of the fluoroscopic imaging assembly, with the source positioned at any available SID, provided that the end of the beam-limiting device or spacer is no closer than 30 cm from the input surface of the fluoroscopic imaging assembly.

5.6.4 In a C-arm type of fluoroscope having an SID less than 45 cm, the AKR shall be measured at the minimum SSD.

5.6.5 In a lateral type of fluoroscope, the air kerma rate shall be measured at a point 15 cm from the centerline of the x-ray table and in the direction of the x-ray source with the end of the beam-limiting device or spacer positioned as closely as possible to the point of measurement. If the tabletop is movable, it shall be positioned as closely as possible to the lateral x-ray source, with the end of the beam-limiting device or spacer no closer than 15 cm to the centerline of the x-ray table.

5.7 Exemptions. Fluoroscopic radiation therapy simulation systems are exempt from the requirements set forth in this subsection when used for therapy simulation purposes.

5.8 Reserved.

5.9 Indication of potential and current. During fluoroscopy and cinefluorography, x-ray tube potential and current shall be continuously indicated. Deviation of x-ray tube potential and current from the indicated value shall not exceed the maximum deviation as stated by the manufacturer.

5.10 Source-skin distance.

5.10.1 Means shall be provided to limit the source-skin distance to not less than 38 cm on stationary fluoroscopes and to not less than 30 cm on mobile and portable fluoroscopes. In addition, for fluoroscopes intended for specific surgical application that would be prohibited at the source-skin distances specified in this paragraph, provisions may be made for operating at shorter source-skin distances but in no case less than 20 cm.

5.10.2 For stationary, mobile, or portable C-arm fluoroscopic systems manufactured on or after June 10, 2006, having a maximum source-image receptor distance of less than 45 cm, means shall be provided to limit the source-skin distance to not less than 19 cm. Such systems shall be labeled for extremity use only. In addition, for those systems intended for specific surgical application that would be prohibited at the source-skin distance specified in this paragraph, provisions may be made for operation at shorter source-skin distances but in no case less than 10 cm.

5.11 Fluoroscopic irradiation time, display, and signal.

5.11.1 Fluoroscopic equipment manufactured before June 10, 2006:

5.11.1.1 Shall be provided with means to preset the cumulative irradiation time of the fluoroscopic tube. The maximum cumulative time of the timing device shall not exceed 5 minutes without resetting. A signal audible to the fluoroscopist shall indicate the completion of any preset cumulative irradiation time. Such signal shall continue to sound while x-rays are produced until the timing device is reset. Fluoroscopic equipment may be modified in accordance with 21 CFR 1020.30(q) to comply with the requirements of this paragraph. When the equipment is modified, it shall bear a label indicating the statement:

5.12 Modified to comply with 21 CFR 1020.32(h)(2)

5.12.1 As an alternative to the requirements of this paragraph, radiation therapy simulation systems may be provided with a means to indicate the total cumulative exposure time during which x-rays were produced, and which is capable of being reset between x-ray examinations.

5.13 For x-ray controls manufactured on or after June 10, 2006, there shall be provided for each fluoroscopic tube:

5.13.1 A display of the fluoroscopic irradiation time at the fluoroscopist’s working position. This display shall function independently of the audible signal described in this subsection. The following requirements apply:

5.13.1.1 When the x-ray tube is activated, the fluoroscopic irradiation time in minutes and tenths of minutes shall be continuously displayed and updated at least once every 6 seconds.

5.13.1.2 The fluoroscopic irradiation time shall also be displayed within 6 seconds of termination of an exposure and remain displayed until reset.

5.13.1.3 Means shall be provided to reset the display to zero prior to the beginning of a new examination or procedure.

5.13.2 A signal audible to the fluoroscopist shall sound for each passage of 5 minutes of fluoroscopic irradiation time during an examination or procedure. The signal shall sound until manually reset or, if automatically reset, for at least 2 seconds.

5.14 Mobile and portable fluoroscopes. In addition to the other requirements of this subsection, mobile and portable fluoroscopes shall provide an image receptor incorporating more than a simple fluorescent screen.

5.15 Display of last-image-hold (LIH). Fluoroscopic equipment manufactured on or after June 10, 2006, shall be equipped with means to display LIH image following termination of the fluoroscopic exposure.

5.16 For an LIH image obtained by retaining pretermination fluoroscopic images, if the number of images and method of combining images are selectable by the user, the selection shall be indicated prior to initiation of the fluoroscopic exposure.

5.17 For an LIH image obtained by initiating a separate radiographic-like exposure at the termination of fluoroscopic imaging, the technique factors for the LIH image shall be selectable prior to the fluoroscopic exposure, and the combination selected shall be indicated prior to initiation of the fluoroscopic exposure.

5.18 Means shall be provided to clearly indicate to the user whether a displayed image is the LIH radiograph or fluoroscopy. Display of the LIH radiograph shall be replaced by the fluoroscopic image concurrently with re-initiation of fluoroscopic exposure, unless separate displays are provided for the LIH radiograph and fluoroscopic images.

5.19 Displays of values of AKR and cumulative air kerma. Fluoroscopic equipment manufactured on or after June 10, 2006, shall display at the fluoroscopist’s working position the AKR and cumulative air kerma. The following requirements apply for each x-ray tube used during an examination or procedure:

5.20 When the x-ray tube is activated and the number of images produced per unit time is greater than six images per second, the AKR in mGy/min shall be continuously displayed and updated at least once every second.

5.21 The cumulative air kerma in units of mGy shall be displayed either within 5 seconds of termination of an exposure or displayed continuously and updated at least once every 5 seconds.

5.22 The display of the AKR shall be clearly distinguishable from the display of the cumulative air kerma.

5.23 The AKR and cumulative air kerma shall represent the value for conditions of free-in-air irradiation at one of the following reference locations specified according to the type of fluoroscope.

5.23.1 For fluoroscopes with x-ray source below the x-ray table, x-ray source above the table, or of lateral type, the reference location shall be the respective locations specified in 5.7.1, 5.7.2 or 5.7.5.

5.23.2 For C-arm fluoroscopes, the reference location shall be 15 cm from the isocenter toward the x-ray source along the beam axis. Alternatively, the reference location shall be at a point specified by the manufacturer to represent the location of the intersection of the x-ray beam with the patient’s skin.

5.24 Means shall be provided to reset to zero the display of cumulative air kerma prior to the commencement of a new examination or procedure.

5.25 The displayed AKR and cumulative air kerma shall not deviate from the actual values by more than ±35 percent over the range of 6 mGy/min and 100 mGy to the maximum indication of AKR and cumulative air kerma, respectively. Compliance shall be determined with an irradiation time greater than 3 seconds.

5.26 Control of Scattered Radiation.

5.26.1 Fluoroscopic table designs when combined with procedures utilized shall be such that no unprotected part of any staff or ancillary individual's body shall be exposed to unattenuated scattered radiation which originates from under the table. The attenuation required shall be not less than 0.25 millimeter lead equivalent.

5.26.2 Equipment configuration when combined with procedures shall be such that no portion of any staff or ancillary individual's body, except the extremities, shall be exposed to the unattenuated scattered radiation emanating from above the tabletop unless that individual:

5.26.2.1 Is at least 120 centimeters from the center of the useful beam; or

5.26.2.2 The radiation has passed through not less than 0.25 millimeter lead equivalent material including, but not limited to, drapes, Bucky-slot cover panel, or self-supporting curtains, in addition to any lead equivalency provided by the protective apron referred to in 3.1.5.2.

5.27 The Agency may grant exemptions to 5.24.2. where a sterile field will not permit the use of the normal protective barriers. Where the use of prefitted sterilized covers for the barriers is practical, the Agency shall not permit such exemption. See Appendix C for a suggested list of fluoroscopic procedures where such exemptions will be automatically granted.

5.28 Operator Qualifications.

5.28.1 The facility shall ensure that only a licensed practitioner of the healing arts or a radiologic technologist be allowed to operate fluoroscopic x-ray systems. A licensed practitioner includes any health practitioner of the healing Arts who is licensed in the state to diagnose and treat individuals and who operates within the scope defined in the state law. This includes physicians and physician assistants and excludes nurse practitioners.