department of natural resources and environmental control

Division of Air and Waste Management

FINAL

REGISTER NOTICE

SAN # 2010-22

1142 Specific Emission Control Requirements

1. Introduction

In November 2009, Delaware promulgated Section 2.0 of 7 DE Admin. Code 1142, Control of NOx Emissions from Industrial Boilers and Process Heaters at Petroleum Refineries. In June 2010, Section 2.0 of 1142 was approved by the Environmental Protection Agency (EPA) into Delaware’s State Implementation Plan (SIP) (75 FR 31711).

The purpose of Section 2.0 of 7 DE Admin. Code 1142 is to reduce nitrogen oxides (NOx) emissions from large industrial boilers and process heaters that are located at petroleum refineries. This reduction in NOx emissions from the affected units would aid in the attainment and maintenance of any national ambient air quality standard (NAAQS), and any other applicable requirement that is affected by NOx emissions. NAAQSs and applicable requirements that are affected by NOx emissions are:

Under the 1997 ozone NAAQS the entire state of Delaware is included as part of a Philadelphia based non-attainment area (NAA). Delaware submitted to the EPA an attainment demonstration SIP in July 2007 which demonstrated that the NAA would attain compliance with that NAAQS by 2010. EPA has not yet issued area designations for the 2008 revised NAAQS, and has not yet finalized its reconsideration of the 2008 revised NAAQS.

Under the 1997 NAAQS New Castle County Delaware is included as part of a Philadelphia based NAA. Delaware submitted to the EPA an attainment demonstration SIP in April 2008 which demonstrated that the NAA would attain compliance with the NAAQS by 20101. Relative to the 2006 PM2.5 NAAQS, New Castle County Delaware is designated as non-attainment for the daily standard, and is included as part of the Philadelphia based NAA. The attainment demonstration SIP is due in December 2012.2

The State of Delaware submitted to the EPA in September 2009 a Visibility SIP that met the requirements of Part C to Title I of the CAA. This SIP primarily relied upon SO2 reductions, because sulfate was determined by the Regional Planning Organizations to be the main cause of visibility impairment in Class I areas. However, the SIP also partially relied on reductions in NOx emissions to demonstrate that Delaware has met its 2018 visibility related goals.

EPA has not issued designations of areas under the 2010 revised NAAQS, and State recommendations for designation of areas are due to the EPA in January 2011.

Section 2.0 of 7 DE Admin. Code 1142 does not limit emissions of any pollutant other than NOx. Section 2.0 covers nine (9) emission units at the Delaware City Refinery, and imposes compliance dates between 2007 and 2012, depending on the particular emission unit.

In 2009 the operations of equipment at the Delaware City Refinery were discontinued, and in 2010 the refinery ownership changed from Premcor Refining Group Inc. to Delaware City Refining Company, LLC (“DCRC”). Two actions related to this change in ownership impact Delaware’s SIP:

In a separate regulatory process, Delaware is proposing to revise Section 2.0 of 7 DE Admin. Code 1142 to (1) provide for the control of NOx from the Fluid Catalytic Cracking Unit CO boiler to the level that was previously required by the 2008 consent agreement, and (2) provide for a facility-wide NOx emission cap compliance alternative. The purpose of this SIP revision is to demonstrate that these revisions to Section 2.0 of 7 DE Admin. Code 1142 will not interfere with attainment or maintenance of any NAAQS, or any other applicable requirement of the CAA.

Questions or comments regarding this SIP revision should be addressed to Ronald A. Amirikian, Planning Branch Manager, Division of Air Quality, Delaware Department of Natural Resources and Environmental Control, at (302) 739-9402 or ronald.amirikian@state.de.us.

2. Impact Analysis

Section 2.0 of 7 DE Admin. Code 1142 sets emission limits only for the pollutant NOx, and only impacts the Delaware City Refinery (i.e., the Delaware City Refinery is the only petroleum refinery within the State of Delaware). This analysis considers the effect the revisions to Section 2.0 of 7 DE Admin. Code 1142 have on applicable requirements for which NOx emissions are a precursor or pollutant of interest. That is, the pollutants ozone, PM2.5, visibility, and NO2.

2.1 Baseline NOx emissions from the Delaware City Refinery.

Ozone. 2002 is the SIP base year for planning associated with the 1997 0.08 ppm ozone NAAQS. Actual 2002 base year NOx emissions from the Delaware City Refinery were 3,555 TPY. For the 2008 revised NAAQS, which is currently being reconsidered, a SIP planning base year has not yet been determined. The most current emission inventory is 2008, and actual 2008 NOx emissions from the Delaware City Refinery were 2,525 TPY.

PM2.5. 2002 is the SIP base year for planning associated with the 2008 PM2.5 15 ug/m3 annual, and the 65 ug/m3 daily NAAQSs. Base year 2002 NOx emissions are identical to those identified under ozone above. For the 2008 revised NAAQS, a SIP planning base year has not yet been determined. The most current emission inventory is 2008, and actual 2008 NOX emissions from the Delaware City Refinery were those identified under ozone above.

Visibility. 2002 is the SIP base year for planning associated with Delaware’s 2008 Visibility SIP. Base year 2002 NOx emissions are those identified under ozone above.

NO2. For the 2010 revised NAAQS, area designation has not yet occurred, and a SIP planning base year has not yet been determined. The most current emission inventory is 2008, and actual 2008 NOx emissions from the Delaware City Refinery were those identified under ozone above.

2.2 Projected NOx emissions from the Delaware City Refinery under current (i.e., before revision) Section 2.0 of 7 DE Admin. Code 1142.

Ozone. Delaware’s 2007 Ozone SIP demonstrates that compliance with the 1997 0.08ppm ozone NAAQS will be achieved in 2009, based on 2009 projected emission levels. 2002 was the SIP base year, and 2002 base year NOx emissions (see 2.1 above) were projected to 2009 by applying factors that account for projected growth and controls. The projection calculations are explained in detail in the 2007 ozone SIP.

The following five (5) emission units received post-2002/Pre-2009 emission controls that were relied upon in the 2007 ozone SIP calculations5:

Resultant 2009 attainment year emissions from the Delaware City Refinery (i.e., those after the application of growth, the 41-H-1 shutdown, the control of Units 80-1, 80-2, 21-H-2, and the Cracker CO boiler) were estimated at 2,855 TPY.

PM2.5. Delaware’s 2008 PM2.5 SIP demonstrates that compliance with the 1997 15 ug/m3 annual, and the 65 ug/m3 daily standards will be achieved in 2009, based on 2009 projected emission levels. 2002 was the SIP base year, and 2002 base year NOx emissions (see 2.1 above) were projected to 2009 by applying factors that account for projected growth and controls. The projection calculations are those discussed under ozone above.

Visibility. Delaware’s 2009 Visibility SIP is based on 2018 projected emission levels.

Section 2.0 of 7 DE Admin. Code 1142 provides for compliance dates between 2009 and 2012. In 2012 the requirements of 7 DE Admin. Code are fully implemented. As part of Delaware’s 2009 Visibility SIP, 2002 NOx emissions from the Delaware City Refinery were projected to be 2,761 TPY, and 2,774 TPY, for 2012 and 2018, respectively.

The 1142 related NOx controls relied upon in the Visibility SIP were:

NO2. For the 2010 revised NAAQS, area designation has not yet occurred. The 2002 and 2008 actual NOx emissions, and the 2009, 2012 and 2018 projected NOx emissions discussed above are used to evaluate the impact that the revisions to Section 2.0 of 7 DE Admin. Code 1142 would have on future NO2 NAAQS planning.

2.3 Revision to Section 2.0 of 7 DE Admin. Code 1142.

Delaware is revising Section 2.0 of 7 DE Admin. Code 1142 to (1) provide for the control of NOx emissions from the Fluid Catalytic Cracking Unit CO Boiler (Unit 23-H-3) that was previously required under a 2008 consent decree, and (2) provide for, as an option, compliance with a facility-wide NOx cap as an alternative to unit specific NOx emission limitations.

The initial facility-wide cap is being established at the level of Premcor’s actual 2008 NOx emissions (i.e., 2,525 TPY), and will decline in two step decreases, as follows:

Under the revised Section 2.0 of 7 DE Admin. Code 1142, either all of the unit specific NOx emission limitations apply or the facility-wide cap apply at all times (i.e., there is no gap in compliance).

2.4 Impact of Revised 7 DE Admin. Code 1142 on ozone, PM2.5, visibility and NO2, (i.e., the requirements for which NOx emissions are a precursor or pollutant of interest).

The addition of emission limits to Section 2.0 of 7 DE Admin. Code 1142 applicable to Unit 23-H-3 do not in any way change the emission limits for this unit. That is, the emissions limit for Unit 23-H-3 do not change, but only the vehicle by which these emission limits will be enforced is changing (i.e., it will be enforced through Section 2.0 of 7 DE Admin Code 1142 instead of a consent agreement). In other words, no change is being made that could upset the status quo.

With the revision to 2.0 of 7 DE Admin. Code 1142 described in 2.3 above, the Delaware City Refinery may comply by either (1) complying with all of the unit specific emission limitations specified in 7 DE Admin. Code 1142, or (2) complying with the applicable facility-wide NOx emission cap.

This is the current compliance mechanism in Section 2.0 of 7 DE Admin. Code 1142. Therefore, since overall no change is being made to the unit specific emission rates this compliance option would not impact any NAAQS or applicable requirement (i.e., no change is being made that could upset the status quo).

Compliance with the 7 DE Admin. Code 1142 facility-wide caps is required monthly, on a 12-month rolling basis. For standards where compliance is demonstrated on an annual or longer basis, an annual cap is generally consistent with a NAAQS with an annual averaging period.

The NO2 and PM2.5 NAAQS both have a standard which is averaged on an “annual” basis. For the NO2 annual NAAQS, this is the arithmetic average of all of the reported 1-hour values (40 CFR Part 50, Appendix S). For both of the PM2.5 annual NAAQSs (1997 and 2006), the annual standard design value, which is based upon 3 years of valid annual means, is compared to the NAAQS (40 CFR Part 50 Appendix N). The design value is an average of three annual means over three consecutive years. An annual mean is the average of the average values for each of the four quarters in a calendar year; the average value for each quarter is the average of the daily values for that quarter.

As long as the cap set by 7 DE Admin. Code 1142 is lower than a baseline condition (i.e., 7 DE Admin. Code 1142 before amendment), a conclusion that the revised Section 2.0 of 7 DE Admin. Code 1142 will cause no worsening of air quality is supported.

The table below summarizes the Delaware City Refinery NOx emission data presented in 2.1 and 2.2 above.

|

Year |

NOx (TPY) |

|

2002 (actual) |

3,555 |

|

2008 (actual) |

2,525 |

|

2009 (projected) |

2,855 |

|

2012 (projected) |

2,761 |

|

2018 (projected) |

2,774 |

As discussed in 2.3 above, the facility-wide NOx cap will start at 2,525 TPY, and decline to 1,650 TPY in 2015. This declining cap option provides for emissions that are lower than the actual and projected emission levels under the current unit specific control option. This indicates that the facility-wide NOx emission cap compliance option will not negatively impact the 1997 and 2006 annual PM2.5 NAAQSs, the 2010 annual NO2 NAAQS, and visibility related goals

The 1997 and 2008 ozone NAAQSs is directly related to the highest concentration averaged over an 8-hour period in any one (calendar) day. The 2010 daily NO2 NAAQS is determined by comparing the 1-hour primary standard design value, which is the average of three annual 98th percentile values, to the NAAQS (40 CFR Part 50, Appendix S). Likewise, compliance with the 1997 and 2006 24-hour PM2.5 NAAQSs is determined by comparing the 24-hour standard design value, which is an average the annual 98th percentile values for each of three years (40 CFR Part 50 Appendix N).

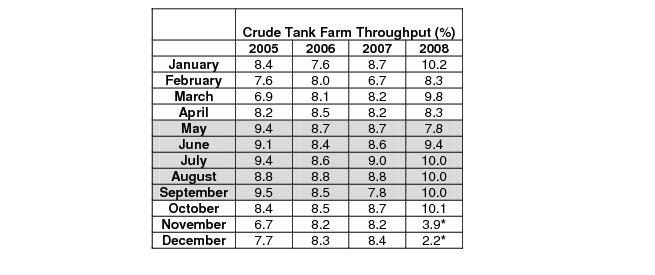

In addition to the comparison between the actual and projected emissions and the facility-wide cap discussed above, seasonal variations were evaluated. The Department analyzed monthly crude oil throughputs from the crude oil tank farm, which is an indicator of the capacity factor of the refinery. Historical throughput is useful data to analyze because such data supports a conclusion that utilization will not drastically vary by month in the future. Four (4) years, 2005 through 2008, were evaluated (see table below).

*Note: November and December of 2008 are determined to be not representative of normal operations. The refinery was running as significantly reduced rates during these months because the crude unit had its turnaround in November 2008 and the Coker was down. Because of this 2008 was not evaluated further.

Based on 2005, 2006 and 2007 crude tank farm throughput, the Department concludes there is a slight bias high during the ozone season months. However, given the monthly deviation is slight (36-month average percent is 8.3, and the standard deviation from the average is 0.7), and given that the facility-wide NOx caps are less than the recent actual and projected emissions, the Department concludes that refinery operations in the future will be essentially uniform throughout the year, and the 12-month rolling caps are consistent with NAAQS and other applicable requirements.

In addition to crude oil throughputs from the crude oil tank farm, the Department has also analyzed the variability of daily emissions from the Delaware City Refinery. This was done by analyzing actual historical NOx emissions for the refinery units that are covered by 7 DE Admin. Code 1139, “Nitrogen Oxides (NOx) Budget Trading Program.” The NOx emissions from units subject to 7 DE Admin. Code 1139 are monitored by continuous emission monitoring systems (CEMS). Historical NOx emissions data for these units were obtained from EPA’s Clean Air Market’s Division (CAMD) at http://camddataandmaps.epa.gov/gdm for calendar years 2005 through 2007.

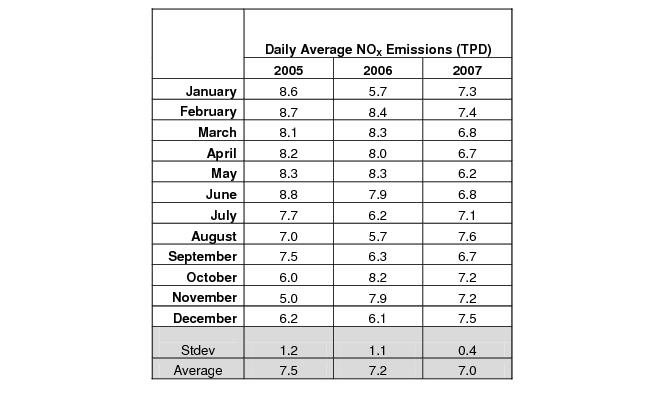

Analysis of Daily Average NOx Emissions: The daily average NOx emissions for all units reporting to CAMD, in TPD, for CY2005, 2006, and 2007, by month, are as follows:

The daily average NOx emissions for each month between January 2005 and December 2007 is within one (1) standard deviation of the annual average daily NOx emissions for each month for all three (3) years, except for June 2005 (which is 1.03 standard deviations from the average). This indicates there is little variation in daily NOx emissions from month to month, and that operations under a 12-month rolling total facility-wide NOx cap will not result in high daily NOx emissions during times of bad air quality, and would not negatively impact applicable requirements.

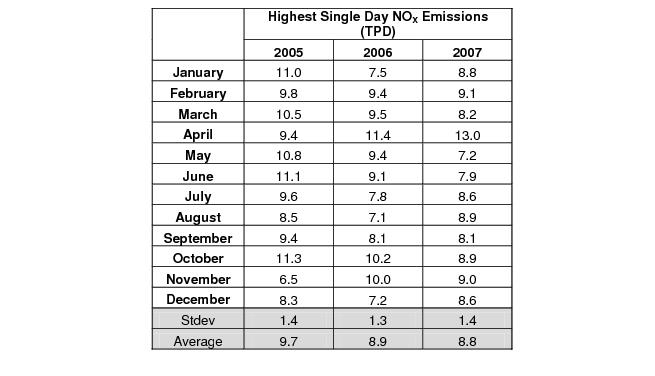

Analysis of Highest Single Day NOx Emissions: The highest single day’s NOx emissions for all units reporting to CAMD, in TPD, for calendar years 2005, 2006, and 2007, by month, are as follows:

Delaware’s air quality is generally worst in the hot summer months of June, July and August. The highest single day NOx emission from the Delaware City Refinery were generally outside of this period. In all three (3) of the years analyzed the highest daily NOx emissions occurred during months were air quality is generally good in Delaware (i.e., October for 2005, and April for 2006 and 2007). In addition, only in three (3) months out of the thirty-six (36) months (i.e., October 2005, April 2006, and April 2007) analyzed did the highest single day NOx emission exceed the highest single day annual average plus one (1) standard deviation. This indicates that operations under a 12-month rolling total facility-wide NOx cap will not provide for high emissions on bad air quality days, and will not negatively impact applicable requirements.

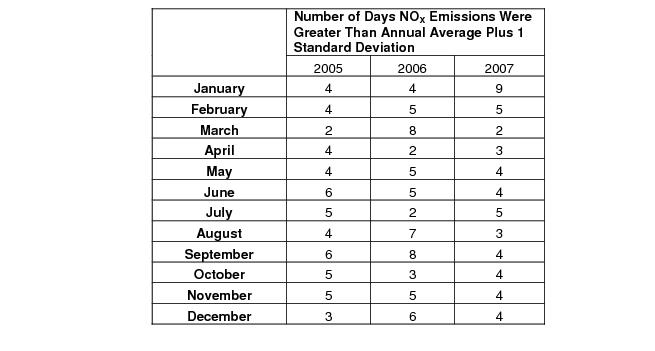

Analysis of the Number of Days that NOX Emissions exceed Annual Average plus 1 standard deviation: The table below shows the number of days were daily NOx emission were greater than the annual average emissions plus one (1) standard deviation.

Out of these three (3) years, the maximum number of days that the daily NOx emissions exceed the mean/average plus one (1) standard deviation was only 9 (January 2007). On only seven (7) out of these thirty-six (36) months did the daily NOx emissions exceed one (1) standard deviation more than 5 times. And, the number of times the daily NOx emissions exceeded one (1) standard deviation is constant from month to month.

The above analysis indicates that relative to the 1997 ozone NAAQS, the planning assumptions used in the 2007 attainment demonstration SIP would not be undermined by the revisions to Section 2.0 of 7 DE Admin. Code 1142. This is because refinery operations do not vary significantly from month to month, and actual emissions levels do not vary significantly over an ozone season or do not vary significantly on a daily basis within the months of the ozone season. Relative to the 2008 ozone NAAQS, planning is now underway but base year and attainment years have not yet been set. Preservation of the status quo air quality will prevent interference with Delawares’ obligations to develop timely attainment demonstrations, and no interference with the ozone NAAQS (i.e., no change is being made that would upset the status quo).

Relative to the daily standard of the 2006 PM2.5 NAAQS (which sets a lower threshold than the 1997 daily NAAQS and would address the daily standard under the 1997 NAAQS for which New Castle County is in attainment), the above analysis also indicates that the planning assumptions used in the 2008 attainment demonstration SIP would not be undermined by the revisions to Section 2.0 of 7 DE Admin. Code 1142 (i.e., a 12-month rolling cap is consistent with attainment because refinery utilization and emissions do not vary significantly from month to month or from day to day).

Relative to the NO2 NAAQS, area designations have not yet occurred. Because refinery operations do not vary significantly from month to month, and actual emissions levels do not vary significantly over the year, preservation of the status quo air quality will prevent interference with Delawares’ obligations to develop timely attainment demonstrations, and no interference with the NO2 NAAQS (i.e., no change is being made that would upset the status quo).

3. Conclusion

Delaware concludes that the revisions to Section 2.0 of 7 DE Admin. Code 1142 to 1) include the NOx control requirement for the Fluid Catalytic Cracking Unit CO boiler that were previously provided for in a 2008 consent agreement and 2) provide for a facility-wide NOx cap compliance alternative will not interfere with attainment or maintenance of any NAAQS or any other applicable requirement of the CAA

1142 Specific Emission Control Requirements

1.1 Purpose

New Castle County and Kent County are part of the Philadelphia-Wilmington-Trenton 1-hour ozone non-attainment area. All areas of Delaware impact this non-attainment area. On December 19, 1999, the EPA identified an emission reduction “shortfall” associated with this non-attainment area. Promulgation of 1.0 of this regulation is one measure that the Department is taking to mitigate this shortfall.

In determining the applicability of 1.0 of this regulation, the Department attempted to minimize the impact on facilities that recently installed NOx controls under 7 DE Admin. Code 1112 (NOx RACT) and 7 DE Admin. Code 1137/1139 (NOx Budget Trading Program). The Department did this by regulating only large sources that, as of the effective date of 1.0 of this regulation, emitted NOX at a rate greater than the rate identified in Table 3-1 of 7 DE Admin. Code 1112, were not equipped with NOx emission control technology, and were not subject to the requirements of 7 DE Admin. Code 1139. In effect, 1.0 of this regulation regulates sources that remain high NOx emitters after the application of RACT and post RACT requirements, and that have not committed substantial capital funds to reduce NOx emissions.

1.2 Applicability

1.2.1 The provisions of 1.0 of this regulation apply to any person that owns or operates any combustion unit with a maximum heat input capacity of equal to or greater than 100 million btu per hour, except that 1.0 of this regulation shall not apply to any unit that, as of the effective date of 1.0 of this regulation:

1.2.1.1 Emits NOx at a rate equal to or less than the rate identified in Table 3-1 of DE Admin. Code 1112.

1.2.1.2 Is equipped with low NOx burner, flue gas recirculation, selective catalytic reduction, or selective non-catalytic reduction technology.

1.2.1.3 Is subject to the requirements of 7 DE Admin. Code 1139.

1.2.2 The requirements of 1.0 of this regulation are in addition to all other state and federal requirements.

1.2.3 Affected persons shall comply with the requirements of 1.3 of this regulation as soon as practicable, but no later than May 1, 2004.

1.3 Standards.

1.3.1 The NOx emission rate from any unit subject to 1.0 of this regulation shall be equal to or less than the following:

1.3.1.1 Between May 1st through September 30th of each year, inclusive: 0.10 lb/mmBTU, 24-hour calendar day average.

1.3.1.2 During all times that gaseous fuel is being fired: 0.10 lb/mmBTU, 24-hour calendar day average.

1.3.1.3 During all times not covered by 1.3.1.1 and 1.3.1.2 of this regulation: 0.25 lb/mmBTU, 24-hour calendar day average.

1.3.2 As an alternative to compliance with the requirements of 1.3.1 of this regulation, compliance may be achieved through the procurement and retirement of NOx allowances authorized for use under 7 DE Admin. Code 1139, as follows:

1.3.2.1 The actual 24-hour calendar day average NOx emission rate in pounds per million btu shall be determined for each day of unit operation, using CEMs operated in accordance with 1.4 of this regulation.

1.3.2.2 The actual heat input to each unit in million btu shall be determined for each day of unit operation, using methods proposed by the person subject to 1.0 of this regulation and acceptable to the Department.

1.3.2.3 0.10 or 0.25, as applicable and consistent with 1.3.1 of this regulation, shall be subtracted from the rate determined in 1.3.2.1 of this regulation.

1.3.2.4 To obtain the number of pounds of NOx emitted for a particular day, the emission rate determined in 1.3.2.3 of this regulation shall be multiplied by the heat input to the unit for that day determined in 1.3.2.2 of this regulation. If the emission rate determined in 1.3.2.3 of this regulation is equal to or less than zero, then the number of pounds of NOx emitted for that day shall be zero.

1.3.2.5 Not later than the 20th day of each month:

1.3.2.5.1 The number of pounds of NOx emissions calculated pursuant to 1.3.2.4 of this regulation shall be summed for each calendar month, the result shall be divided by 2000, and shall be rounded to the nearest whole ton.

1.3.2.5.2 For each ton of NOx emissions calculated pursuant to 1.3.2.5.1 of this regulation, records shall be maintained demonstrating that one NOx allowance owned by the person subject to 1.0 of this regulation is identified and available, by serial number, for retirement.

1.3.2.6 Not later than February 1 of each calendar year, the NOx allowances identified pursuant to 1.3.2.5.2 of this regulation for the previous calendar year, shall be submitted to the Department for retirement. Such submission shall detail the calculations specified in 1.3.2.1 through 1.3.2.5 of this regulation, and shall indicate the serial number of each allowance to be retired.

1.4 Monitoring Requirements. Compliance with the NOx emission standards specified in 1.0 of this regulation shall be determined based on CEM data collected in accordance with the requirements of 3.1.2 of 7 DE Admin. Code 1117 (Performance Specification 2), and in compliance with the requirements of 40 CFR, Part 60, Appendix F.

1.5 Recordkeeping and Reporting Requirements.

1.5.1 Not later than 180 days after the effective date of 1.0 of this regulation, any person subject to 1.0 of this regulation shall develop, and submit to the Department for approval, a schedule for bringing the affected emission unit or units into compliance with the requirements of 1.0 of this regulation. Such schedule shall include, at a minimum, all of the following:

1.5.1.1 The method by which compliance will be achieved

1.5.1.2 The dates by which the affected person commits to completing the following major increments of progress, as applicable:

1.5.1.2.1 Completion of engineering;

1.5.1.2.2 Submission of permit applications;

1.5.1.2.3 Awarding of contracts for construction or installation;

1.5.1.2.4 Initiation of construction;

1.5.1.2.5 Completion of construction;

1.5.1.2.6 Commencement of trial operation;

1.5.1.2.7 Initial compliance testing;

1.5.1.2.8 Submission of compliance testing reports;

1.5.1.2.9 Commencement of normal operations (in full compliance).

1.5.2 Any person subject to 1.0 of this regulation shall submit to the Department an initial compliance certification not later than May 1, 2004. The initial compliance certification shall, at a minimum, include the following information:

1.5.2.1 The name and the location of the facility.

1.5.2.2 The address and telephone number of the person responsible for the facility.

1.5.2.3 Identification of the subject source or sources.

1.5.2.4 The applicable standard.

1.5.2.5 The method of compliance.

1.5.2.6 Certification that each subject source is in compliance with the applicable standard

1.5.2.7 All records necessary for determining compliance with the standards of 1.0 of this regulation shall be maintained at the facility for a period of five years.

1.5.3 Any person subject to 1.0 of this regulation shall, for each occurrence of excess emissions, within 30 calendar days of becoming aware of such occurrence, supply the Department with the following information:

1.5.3.1 The name and location of the facility.

1.5.3.2 The subject source or sources that caused the excess emissions.

1.5.3.3 The time and date of first observation of the excess emissions.

1.5.3.4 The cause and expected duration of the excess emissions.

1.5.3.5 The estimated rate of emissions (expressed in the units of the applicable emission limitation) and the operating data and calculations used in determining the magnitude of the excess emissions.

1.5.3.6 The proposed corrective actions and schedule to correct the conditions causing the excess emissions.

1.5.4 Any person subject to 1.0 of this regulation shall maintain all information necessary to demonstrate compliance with the requirements of 1.0 of this regulation for a minimum period of five years. Such information shall be immediately made available to the Department upon verbal and written request.

2.1 Purpose

2.1.1 The purpose of Section 2.0 of this regulation is to reduce NOXx emissions from Delaware's large industrial boilers and process heaters that are located at petroleum refineries.

2.1.2 Under the 8-hour ozone national ambient air quality standard (NAAQS), the state of Delaware is part of the Philadelphia-Wilmington-Atlantic City, PA-DE-MD-NJ moderate non-attainment area (NAA). The entire NAA, including Delaware, is required by the Clean Air Act (CAA) to attain the 8-hour ozone NAAQS by 2010. After attainment, the area must maintain compliance with the NAAQS. By implementing Section 2.0 of this regulation, NOx emission reductions from the affected boilers and heaters shall contribute to (1) attainment and maintenance of the 8-hour ozone standard, and (2) improvement of the ambient air quality, in both Delaware and the entire NAA.

2.1.3 Additionally, New Castle County of Delaware is a part of the Philadelphia-Wilmington-Camden, PA-DE-NJ NAA for the annual fine particulate matter (PM2.5) NAAQS, and is required by the CAA to attain the NAAQS by 2010. Since NOx is a significant precursor to PM2.5 formation, reducing NOx emissions will also assist in attainment and maintenance of the PM2.5 standard.

2.2 Applicability and Compliance Dates

2.2.1 Section 2.0 of this regulation applies to any industrial boiler or process heater with a maximum heat input capacity of equal to or greater than 200 million BTUs per hour (mmBTU/Hour) (except for any Fluid Catalytic Cracking Unit carbon monoxide (CO) boiler), which is operated or permitted to operate within a petroleum refinery facility on the effective date of this section July 11, 2007. This comprises the following nine (9) ten (10) units at the Delaware City refinery:

2.2.1.1 Crude Unit Vacuum Heater (Unit 21-H-2);

2.2.1.2 Crude Unit Atmospheric Heater (Unit 21-H-701);

2.2.1.3 Fluid Coking Unit Carbon Monoxide boiler (Unit 22-H-3);

2.2.1.4 Steam Methane Reformer Heater (Unit 37-H-1);

2.2.1.5 Continuous Catalyst Regenerator Reformer Heater (Unit 42-H-1,2,3);

2.2.1.6 Boiler 1 (Unit 80-1);

2.2.1.7 Boiler 2 (Unit 80-2);

2.2.1.8 Boiler 3 (Unit 80-3);

2.2.1.9 Boiler 4 (Unit 80-4).

2.2.1.10 Fluid Catalytic Cracking Unit Carbon Monoxide (CO) boiler (Unit 23-H-3).

2.2.2 The requirements of Section 2.0 of this regulation are in addition to all other state and federal requirements.

2.2.3 The following units shall be in compliance with the requirements of Section 2.0 of this regulation on and after July 11, 2007: Crude Unit Atmospheric Heater (Unit 21-H-701), Steam Methane Reformer Heater (Unit 37-H-1) and Boiler 2 (Unit 80-2).

2.2.4 The following units shall be in compliance with the requirements of Section 2.0 of this regulation as soon as practicable, but not later than:

2.2.4.1 December 31, 2008: Boiler 1 (Unit 80-1) and Crude Unit vacuum Heater (Unit 21-H-2), and Fluid Catalytic Cracking Unit CO boiler (Unit 42-H-1, 2, 3).

2.2.4.2 May 1, 2011: Boiler 3 (Unit 80-3) and Boiler 4 (Unit 80-4).

2.2.4.3 December 31, 2012: Continuous Catalyst Regenerator Reformer Heater (Unit 42-H-1, 2, 3).

2.3 Standards.

2.3.1 Except as provided for in 2.3.2 of this regulation, Tthe owner or operator of any industrial boiler or process heater identified in Section 2.2.1 of this regulation shall meet not operate except in compliance with the applicable NOx emission limitation identified in the following sections:

2.3.1.1 For the Fluid Coking Unit Carbon Monoxide boiler (Unit 22-H-3), Reserved.

2.3.1.2 For the Steam Methane Reformer (SMR) Heater (Unit 37-H-1), Reserved.

2.3.1.3 For Boiler 1 (Unit 80-1), Boiler 3 (Unit 80-3) and Boiler 4 (Unit 80-4), 0.015 lb/mmBTU, on a 24-hour rolling average basis.

2.3.1.4 For the Fluid Catalytic Cracking Unit CO boiler (Unit 23-H-3), 20 ppmvd @ 0 % O2 on a 365 day rolling average basis, and 40 ppmvd @ 0 % O2 on a 7-day rolling average basis.

2.3.1.45 For any unit not covered by 2.3.1.1, 2.3.1.2, or 2.3.1.3, or 2.3.1.4 0.04 lb/mmBTU, on a 24-hour rolling average basis.

2.3.1.56 The standards set out in 2.3 of this regulation shall not apply to the start-up and shutdown of equipment when emissions from such equipment during a start-up and shutdown are addressed in an operation permit issued pursuant to the provisions of §2 of Regulation 7 DE Admin. Code 1102.

2.3.2 As an alternative to complying with one or more of the unit specific emission limitations specified in 2.3.1 of this regulation the owner or operator of any industrial boiler or process heater identified in Section 2.2.1 of this regulation shall limit the NOx emissions, from all NOx emission sources at the facility, to equal to or less than the applicable emission cap specified in 2.3.2.1 though 2.3.2.3 of this regulation.

2.3.2.1 2,525 tons per year, evaluated over each twelve (12) consecutive month rolling period, for [any each] twelve (12) month rolling period [ending on or before January 2014 commencing with the rolling twelve (12) consecutive month period comprised by calendar year (CY) 2011 and ending with the twelve (12) consecutive month rolling period that ends on December 31, 2013].

2.3.2.2 2,225 tons per year, evaluated over each twelve (12) consecutive month rolling period, [commencing with the twelve (12) month rolling period beginning on December 31, 2013 and ending on December 31, 2014 comprising calendar year 2014].

2.3.2.3 1,650 tons per year, evaluated over each twelve (12) consecutive month rolling period, commencing with the twelve (12) month rolling period beginning on [December 31, 2014 January 1, 2015] and ending on December 31, 2015[, and continuing thereafter].

[2.3.3 Neither the provisions of Section 2.3.2, nor this regulation more generally, shall limit in any way the Department’s authority to establish a lower NOx emission cap and more stringent NOx emission limitations for any source subject to this regulation.]

2.4 Monitoring Compliance Requirements.

2.4.1 Compliance with the NOx emission standards specified in 2.3.1, 2.3.2, and 2.3.4 of this regulation shall be determined based on CEM data collected in accordance with the appropriate requirements set forth in 40 CFR, Part 60, Appendix B, Performance Specification 2, and the QA/QC requirements in 40 CFR Part 60, Appendix F.

2.4.2 Compliance with the facility-wide NOx emission cap specified in 2.3.2 of this regulation shall be determined not later than the last day of each month, as follows.

2.4.2.1 The mass of NOx (tons) emitted [during the prior month] from each [NOx] emission source at the facility [during the prior month subject to the NOx cap] shall be accurately determined using the methods specified in 2.4.2.1.1 through 2.4.2.1.3 of this regulation, as approved by the Department.

2.4.2.1.1 Continuous emission monitoring systems (CEMS) that meet the requirements of 2.4.1 of this regulation [shall be used to determine the emission from any emission unit equipped or required to be equipped with NOx CEMS, or]

2.4.2.1.2 A NOx emission factor that is based upon the results of the most recent performance testing conducted in accordance with a protocol approved by the Department [shall be used to determine the emission from any unit that has conducted or that is required to conduct such performance testing, or]

2.4.2.1.3 Published NOx emission factors for such source or category of sources, or any other method approvable by the Department[, shall be used to determine the emission from any unit not covered by 2.4.2.1.1 or 2.4.2.1.2 of this regulation. Emission factors may be adjusted by the Department to account for the degree of uncertainty or limitations in the factors' development.]

2.4.2.2 NOx emissions from each NOx emission source at the facility shall be determined for all periods of startup, shutdown or malfunction. To the extent that such emissions are not measured by CEMS during such periods of startup, shutdown or malfunction, and to the further extent that performance testing for such source did not establish emission factors for such equipment reflective of operations during periods of startup, shutdown or malfunction, then the owner or operator shall estimate such emission rates from such source during any periods of startup, shutdown or malfunction in accordance with best engineering judgment[, provided however that the owner or operator must report to the Department the basis for the emission projections in such instance, and the Department may object to and modify the emission estimation methodology as it determines appropriate.]

2.4.2.3 The emissions calculated in 2.4.2.1 and 2.4.2.2 of this regulation shall be summed and aggregated with the calculation results for the preceding months as provided for in 2.4.2.3.1 through 2.4.2.3.[34] below.

2.4.2.3.1 For any month before January 2014, the preceding eleven (11) consecutive months shall be included. [No emissions occurring before January 1, 2011 shall be included.]

2.4.2.3.2 For any month in calendar year 2014, only months in calendar year 2014 shall be included.

2.4.2.3.3 For any month in calendar year 2015, only months in calendar year 2015 shall be included.

[2.4.2.3.4 For any month after December 31, 2015, the preceding eleven (11) consecutive months shall be included.]

2.4.2.4 Compliance shall be determined by comparing the results of the calculations in 2.4.2.3 of this regulation with the appropriate NOx emission cap specified in 2.3.2 of this regulation. [Each ton of emissions calculated under 2.4.2.3 of this regulation that is above the applicable NOx emission cap specified in 2.3.2 of this regulation constitutes a violation of 2.0 of this regulation. Following aggregation and summation of emission in accordance with 2.4.2.3, fractions Fractions] of tons shall be rounded up to the next higher number.

2.5 Recordkeeping and Reporting Requirements

2.5.1 Not later than (insert the date that is 180 days after the effective date of this revised Section 2.0) of this regulation, any person subject to Section 2.0 of this regulation shall develop, and submit to the Department, a schedule for bringing the affected emission unit(s), identified in Section 2.2.4, facility into compliance with the requirements of Section 2.3 of this regulation. Such schedule shall include, at a minimum, all of the following:

2.5.1.1 The method by which compliance will be achieved.

2.5.1.2 For persons subject to the requirements of 2.3.1 of this regulation, Tthe dates by which the affected person plans to complete the following major increments of progress, as applicable:

2.5.1.2.1 Completion of engineering;

2.5.1.2.2 Submission of permit applications;

2.5.1.2.3 Awarding of contracts for construction and/or installation;

2.5.1.2.4 Initiation of construction;

2.5.1.2.5 Completion of construction;

2.5.1.2.6 Commencement of trial operation;

2.5.1.2.7 Initial compliance testing;

2.5.1.2.8 Submission of compliance testing reports;

2.5.1.2.9 Commencement of normal operations (in full compliance).

2.5.2 For persons subject to the requirements of 2.3.2 of this regulation, the owner or operator shall submit to the Department [an initial notice that contains] all of the information specified in 2.5.2.1 and 2.5.2.2 of this regulation.

2.5.2.1 The date that compliance with this regulation will begin pursuant to 2.3.2 of this regulation. [A permit application submitted pursuant to 7 DE Admin. Code 1102 or 1130 that contains this information may be used as a means to satisfy this requirement.]

[2.5.2.2 A plan for achieving NOx emission reductions consistent with the NOx caps specified in 2.3.2 of this regulation. This plan shall include the information specified in 2.5.2.2.1 and 2.5.2.2.3 of this regulation.]

2.5.2.2[.1] A list of the emission units at the facility that are required to be included in the facility-wide NOx cap.

[2.5.2.2.2 A report of the monthly NOx emissions from the emission units identified in 2.5.2.2.1 of this regulation, for each of the twelve (12) months that precedes the date specified in 2.5.2.1 of this regulation.

2.5.2.2.3 The current expectation of NOx emission reductions to be achieved at specific individual sources, along with a statement of the anticipated control measures to be utilized and timelines for achieving such emission reductions.]

2.5.23 Any person subject to Section 2.0 the requirements of 2.3.1 of this regulation shall submit to the Department an initial compliance certification by the later of the following dates, or the date the unit first operates after the following date subject to the requirements of 2.3.1: September 10, 2007 for units identified in Section 2.2.3 of this regulation and, for units identified in Section 2.2.4, by the compliance date specified in Section 2.2.4. The initial compliance certification shall include, at a minimum, all of the following information:

2.5.23.1 The name and the location of the facility;

2.5.23.2 The name, address and telephone number of the person responsible for the facility;

2.5.23.3 Identification of the subject source(s);

2.5.23.4 The applicable standard;

2.5.23.5 The method of compliance;

2.5.23.6 Certification that each subject source is in compliance with the applicable standard.

2.5.4 Any person subject to the requirements of 2.3.2 of this regulation shall submit to the Department a semi-annual report [by January 31 and July 31 of each calendar year] that contains all of the information specified in 2.5.4.1 through 2.5.4.5 of this regulation. [At the request of the owner or operator, the Department may change the frequency of such reporting requirements, as may be necessary to harmonize them with reporting requirements of 7 DE Admin. Code 1130, Title V Operating Permits Program.]

2.5.4.1 The identification of owner and operator of the facility.

2.5.4.2 [The total annual NOx emissions (tons/year) from the facility based on a 12-month rolling total for each month in the reporting period recorded pursuant to 2.4.2 of this regulation. A report of the monthly NOx emissions for each source, the basis for determination of the emissions pursuant to 2.4.2.1, and comparison of the rolling total NOx emissions from the facility with the appropriate NOx emission cap that was made pursuant to 2.4.2.4 of this regulation, for each month in the reporting period.]

2.5.4.3 A[n updated] list of the emission units at the facility that are required to be included in the facility-wide NOx cap.

[2.5.4.4 Idenfitcation of any deviation from the monitoring provisions that were approved by the Department pursuant to 2.4.2 of this regulation, and documentation of the alternate methods used to determine emissions.

2.5.4.5 A signed statement by the responsible official certifying the truth, accuracy, and completeness of the information provided in the report.]

2.5.35 Any person subject to Section 2.0 of this regulation shall, for each occurrence of excess emissions above the standards of Section 2.3 of this regulation, including periods when monitoring data was not collected in accordance with procedures appored pursuant to 2.4.2.1 of this regulaiton, within thirty (30) calendar days of becoming aware of such occurrence, supply the Department with the following information:

2.5.35.1 The name and location of the facility;

2.5.35.2 The subject source(s) that caused the excess emissions;

2.5.35.3 The time and date of first observation of the excess emissions;

2.5.35.4 The cause and expected duration of the excess emissions;

2.5.35.5 The estimated rate of emissions (expressed in the units of the applicable emission limitation) and the operating data and calculations used in determining the magnitude of the excess emissions;

2.5.35.6 The proposed corrective actions and schedule to correct the conditions causing the excess emissions.

2.5.46 Any person subject to Section 2.0 of this regulation shall maintain all information necessary to determine and demonstrate compliance with the requirements of this section for a minimum period of five (5) years. Such information shall be immediately made available to the Department upon verbal and written request.