department of natural resources and environmental control

Division of Air and Waste Management

FINAL

Secretary’s Order No.: 2011-A-0021

Date of Issuance: March 16, 2011

Effective Date of the Amendment: April 11, 2011

1124 Control of Volatile Organic Compound Emissions

Under the authority vested in the Secretary of the Department of Natural Resources and Environmental Control (“Department” or “DNREC”) the following findings, reasons and conclusions are entered as an Order of the Secretary in the above-referenced rulemaking proceeding.

Background and Procedural History

This Order considers proposed regulation amendments to 7 DE Admin. Code 1124, Control of Volatile Organic Compound Emissions: Section 47.0, “Offset Lithographic Printing”. The purpose of these proposed amendments is to conform to new Control Techniques Guidelines (CTG) issued by the U.S. Environmental Protection Agency (EPA).

Section 182(b)(2) of the Clean Air Act requires that all ozone non-attainment areas, including Delaware, must develop or update relevant regulations to implement Reasonably Available Control Technology controls on emission sources covered in the U.S. Environmental Protection Agency (“EPA”)’s Control Techniques Guidelines (“CTG”), or Alternative Control Techniques, and submit the regulations to EPA as State Implementation Plan revisions.

Section 47.0 was originally developed in 1994 after EPA issued a CTG in 1993 for control of volatile organic compound (VOC) emissions from the offset lithographic printing industry. In September 2006, the EPA updated its CTG for the offset lithographic printing industry by adding control requirements for letterpress printing operations. To reflect the new requirements in EPA’s 2006 CTG, the Department’s Division of Air Quality (“DAQ”) revised 7 DE Admin. Code 1124, Section 47.0, “Offset Lithographic Printing” in early 2010. The 2010 revision expanded the control scope to include letterpress printing presses, and set up a new and more stringent 95% reduction standard for those control systems installed after the effective date of the proposed revision. After a relevant public comment period, a public hearing was held on June 2, 2010.

Two organizations, Printing Industries of America (“PIA”) and Graphic Arts Association (“GAA”) submitted comments regarding the proposed Section 47.0 prior to the June 2, 2010 hearing. Based on these comments, DAQ determined that substantive changes to the proposed Section 47.0, as set forth in the public hearing of June 2, 2010, were necessary. Two major changes are (1) specifying a one-year transition period for facilities to comply with the new requirements, and (2) providing flexibility for facilities to locate temperature monitoring devices for control systems. These new and substantive changes are reflected in Sections 47.1.2, 47.3.1, 47.5.4.4, 47.4.4, 47.6.1.2.2, and 47.6.3.1. To provide the opportunity for the public to review and comment on these new changes, the Department published a new and revised proposed Section 47.0, established a new public comment period, and scheduled a second public hearing on February 1, 2011 to specifically address those new changes.

The Department’s Division of Air Quality (DAQ) commenced the regulatory development process with Start Action Notice 2010-25. The Department published the proposed regulatory amendments in the January 1, 2011 Delaware Register of Regulations and held a public hearing on February 1, 2011. The Department’s presiding hearing officer, Lisa A. Vest, prepared a Hearing Officer’s Report dated March 8, 2011 (Report). The Report recommends certain findings and the adoption of the proposed revised Amendments as attached to the Report as Appendix A.

Findings and Discussion

I find that the proposed Amendments are well-supported by the record developed by the Department, and adopt the Report to the extent it is consistent with this Order. The Department’s experts in DAQ developed the record and drafted the proposed Amendments. It should be noted that, while the Department received public comments once again from GAA with regard to the proposed revised amendments to the aforementioned Section 47.0 of 7 DE Admin. Code 1124, the Department believes that no additional revisions to this proposed regulatory language is necessary at this time.

I find that the Department’s experts in DAQ fully developed the record to support adoption of these revised Amendments. With the adoption of these revised regulatory amendments, Delaware will have the Department’s regulations conform to EPA’s regulations, as required by the Clean Air Act.

In conclusion, the following findings and conclusions are entered:

1.) The Department has jurisdiction under its statutory authority to issue an Order adopting these proposed Amendments as final;

2.) The Department provided adequate public notice of the proposed revised Amendments, and provided the public with an adequate opportunity to comment on the proposed revised Amendments, including at a public hearing;

3.) The Department held public hearings, initially on June 2, 2010, and then again on February 1, 2011 on the proposed revised Amendments, in order to consider public comments before making any final decision;

4) The Department’s Hearing Officer’s Report, including its recommended record and the recommended revised Amendments as set forth in Appendix A, are adopted to provide additional reasons and findings for this Order;

5.) The recommended revised Amendments were fully vetted to the public, both in legal notices and at the time of the public hearing, and do not reflect any substantive changes from the proposed revised regulation Amendments as published in the January 1, 2011, Delaware Register of Regulations;

6.) The recommended revised Amendments should be adopted as final regulation Amendments because (1) Delaware will be enabled to conform to new CTG as issued by the EPA; (2) the Department’s revisions to Section 47.0 of 7 DE Admin. Code 1124 will enable Delaware to do the following: (i); specify a one-year transition period for facilities to comply with the new requirements, (ii) provide flexibility for facilities to locate temperature monitoring devices for control systems; and (3) the revised regulation amendments are well supported by documents in the record; and that

7.) The Department shall submit this Order approving the final regulation to the Delaware Register of Regulations for publication in its next available issue, and provide such other notice as the law and regulation require and the Department determines is appropriate.

Collin P. O’Mara, Secretary

1124 Control of Volatile Organic Compound Emissions

(Break in Continuity of Sections)

11/29/1994 04/11/2011

47.1 Applicability.

47.1.1 The provisions of 47.0 of this regulation apply to any offset lithographic or letterpress printing press facility, including heatset web, non-heatset web (non-newspaper), non-heatset sheet-fed, and newspaper (non-heatset web) facilities. Except as provided in 47.1.2 of this regulation, every owner or operator of any offset lithographic or letterpress printing press shall comply with the provisions of 47.0 of this regulation on and after [insert effective date of the revised 47.0 of regulation].

47.1.2 Transition period for existing permitted sources. Every owner or operator of any offset lithographic printing press that is subject to a permit issued pursuant to 7 DE Admin Code 1102 or 1130 containing all applicable conditions of 47.0 of this regulation, as that regulation existed on November 29, 1994, shall comply with those permit conditions for up to one year after the effective date of this revision of 47.0 of this regulation. Every owner or operator of any letterpress printing press that is subject to a permit issued pursuant to 7 DE Admin Code 1102 or 1130 shall comply with the permit's conditions for letterpress printing for up to one year after the effective date of this regulation. On and after the date one year after the effective date of this revision of 47.0 of this regulation, every such owner or operator of any offset lithographic or letterpress printing press shall comply with the provisions of 47.0 of this regulation.

47.1.23 Except as specified in 47.6.1 of this regulation, Tthe provisions of 47.0 of this regulation do not apply to any offset lithographic and letterpress printing facility press within a facility whose total actual volatile organic compound (VOC) emissions from all offset lithographic and letterpress printing operations (including emissions from cleaning solutions used on lithographic printing presses) are less than 6.8 kilograms (kg) (15 pounds [lb]) VOCs per day before the application of capture systems and control devices.

47.1.3 The provisions of 47.0 of this regulation do not apply to other types of printing operations, such as flexography, rotogravure, or letterpress.

47.1.4 Existing sources affected by 47.0 of this regulation shall comply with the provisions of 47.0 of this regulation as soon as practicable, but no later than April 1, 1996. New, modified, or reconstructed sources affected by 47.0 of this regulation shall comply with the provisions of 47.0 of this regulation upon startup.

47.1.54 Any facility that becomes or is currently subject to the provisions of 47.0 of this regulation by exceeding the applicability threshold in 47.1.23 of this regulation shall remain subject to these provisions 47.0 of this regulation even if its emissions later fall below the applicability threshold.

47.1.65 Any facility that is currently subject to a state or federal rule promulgated pursuant to the Clean Air Act Amendments of 1977 by exceeding an applicability threshold is and shall remain subject to these provisions, even if its throughput or emissions have fallen or later fall below the applicability threshold.

47.2 Definitions. As used in 47.0 of this regulation, all terms not defined herein shall have the meaning given them in the November 15, 1990 Clean Air Act Amendments (CAAA), or in 2.0 of this regulation.

“Alcohol” means a chemical compound consisting of the hydroxyl (OH) group attached to an alkyl radical and having the general formula CnH2n+1OH, such as ethanol, n-propanol, and iso-propanol.

“Alcohol substitute” means a non-alcohol additive that contains VOCs and is used in the fountain solution to reduce the surface tension of water or to prevent piling (ink build-up).

“Batch” means a supply of fountain solution that is prepared continuously or as a batch and that is used without alteration until completely used or removed from the printing process.

“Cleaning solution” means a liquid that is used to remove ink, including dried ink, and debris from the operating surfaces of the printing press and its parts.

“Dampening system” means equipment that is used to deliver the fountain solution to the lithographic plate.

“Fountain solution” means a mixture of water and non-volatile printing chemicals, and additives which reduce the surface tension of the water. The fountain solution wets the non-image areas so that the ink is maintained within the image areas.

“Heatset” means any operation in which heat is required to evaporate ink oil from the printing ink.

"Letterpress printing" means a printing process in which the image is raised relative to the non-image area and the paste ink is transferred to the substrate directly from the image surface.

“Lithography” or “lithographic printing” means a printing process in which the image and non-image areas are chemically differentiated; the image area is oil-receptive and the non-image area is water-receptive. This method differs from other printing methods, in which the image is a raised or recessed surface.

“Non-heatset” or “coldset” means any operation in which printing inks are set without the use of heat. For the purposes of 47.0 of this regulation, ultraviolet-cured and electron beam-cured inks are considered non-heatset operations.

“Offset lithographic printing” means a printing process in which that transfers the ink film is transferred from the lithographic plate to an intermediary surface (blanket), which, in turn, transfers the ink film to the substrate.

“Press” means a printing production assembly that is composed of one or many units to produce a printed sheet or web.

“Sheet-fed” means a printing operation in which individual sheets of substrate are fed to the press sequentially.

“Total actual VOC emissions” means the quantity of VOCs emitted from all lithographic printing presses and letterpress printing operations, including VOC emissions from cleaning materials and activities, during a particular time period.

“Unit” means the smallest complete printing component of a printing press.

“Web” means a continuous roll of paper used as the printing substrate.

47.3 Standards.

47.3.1 No owner or operator of a heatset offset lithographic printing press or a heatset letterpress printing press shall operate the printing press unless the owner or operator installs a control device to reduces VOC emissions from the press dryer exhaust vent by complying with 47.3.1.1, or 47.3.1.2, or 47.3.1.3 at all time the press operates:

47.3.1.1 At least 90% (weight) of the uncontrolled total organics (minus methane and ethane), or maintains a maximum dryer exhaust outlet concentration of 20 parts per million by volume (ppmv) as methane (as C1), whichever is less stringent when the press is in operation by weight, if the first installation date of the control device is prior to [insert the effective date of this regulation].

47.3.1.2 At least 95%, by weight, if the first installation date of the control device is on or after [insert the effective date of this regulation].

47.3.1.3 Maintaining a maximum press dryer exhaust outlet VOC concentration of 20 parts per million by volume (ppmv) as carbon (C1) on a dry basis,

47.3.2 No owner or operator of an offset lithographic printing press that uses alcohol in the fountain solution shall operate the printing press unless the owner or operator meets one of the requirements listed under 47.3.2..1, 47.3.2.2, or 47.3.2.3, and 47.3.2.4 of this regulation.

47.3.2.1 For any heatset web offset lithographic printing presses,:

47.3.2.1.1 When the fountain solution contains alcohol, the fountain solution on-press (as applied) VOC content shall be maintained at 1.6% or less (by volume). Alternatively, a standard of 3% or less (by volume) alcohol may be used if the fountain solution containing alcohol is refrigerated to less than 15.6 degrees Celsius (°C) (60 degrees Fahrenheit [°F]).:

47.3.2.1.1.1 At 1.6% or less (by volume), or

47.3.2.1.1.2 At 3.0% or less (by volume) and the temperature of the fountain solution shall be maintained at or below 15.5 degrees Celsius (°C) (60 degrees Fahrenheit [°F]).

47.3.2.1.2 When the fountain solution contains no alcohol, the fountain solution on-press (as-applied) VOC content shall be maintained at 3.0% or less (by volume).

47.3.2.2 For any non-heatset web offset lithographic printing presses, the alcohol content in the fountain solution shall be eliminated. Alternatively, non-alcohol additives or alcohol substitutes may be used to accomplish the total elimination of alcohol use.:

47.3.2.2.1 There shall be no alcohol in the fountain solution, and

47.3.2.2.2 The fountain solution on-press (as-applied) VOC content shall be maintained at 3.0% or less (by volume).

47.3.2.3 For any sheet-fed offset lithographic printing presses, the alcohol content in the fountain solution shall be maintained at 5% or less (by volume). Alternatively, a standard of 8.5% or less (by volume) alcohol may be used if the fountain solution is refrigerated to below 15.6°C (60°F) the fountain solution on-press (as-applied) VOC content shall be maintained.

47.3.2.3.1 At 5.0% or less (by volume), or.

47.3.2.3.2 At 8.5% or less (by volume) and the temperature of the fountain solution shall be maintained at or is refrigerated to below 15.65°C (60°F).

47.3.2.4 Any type of offset lithographic printing press shall be considered in compliance with this regulation if the only VOCs in the fountain solution are in non-alcohol additives or alcohol substitutes, so that the concentration of VOCs in the fountain solution is 3.0% or less (by weight). (The fountain solution shall not contain any alcohol.)

47.3.3 No owner or operator of an offset lithographic printing press or a letterpress printing press shall operate the printing press unless the owner or operator reduces VOC emissions from cleaning solutions by meeting requirements in 47.3.3.1, or 47.3.3.2 and 47.3.3.3, of this regulation:

47.3.3.1 uUsing a cleaning solution with a 30% or less (as used) VOC content.

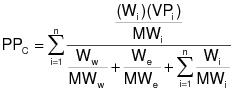

47.3.3.2 Alternatively, the use Using of cleaning solutions with a VOC composite partial vapor pressure less than 10 millimeters (mm) mercury (Hg) (0.4 inches [in] Hg) at 20°C (68°F) may be used. The VOC composite partial vapor pressure is calculated as follows:

Where:

Wi = Weight of the Ith ith VOC compound, in grams (g);

Ww = Weight of water, in g;

We = Weight of exempt compound, in g;

MWi = Molecular weight of the Ith ith VOC compound, in grams per gram-mole  ;

;

MWw = Molecular weight of water, in ;

;

MWe = Molecular weight of exempt compound, in  ;

;

PPC = VOC composite partial pressure at 20°C, in mmHg

VPi = Vapor pressure of the Ith ith VOC compound at 20°C, in mmHg

47.3.3.3 Keeping all cleaning solutions and used shop towels or cloths in closed containers.

47.4 Control Devices. An owner or operator of an offset lithographic printing press or a letterpress printing press equipped with a control system shall ensure that:

47.4.1 The capture system and control device are operated at all times that when the printing press is in operation, and the owner or operator demonstrates compliance with 47.0 of this regulation is demonstrated through the applicable coating analysis and capture system and control device efficiency test methods specified in Appendix B, Appendix D, and Appendix E of of this regulation and in accordance with the capture efficiency test methods specified in Appendix D of this regulation.

47.4.2 The control device is equipped with the applicable monitoring equipment specified in 2.0 of Appendix D of this regulation, and the monitoring equipment is installed, calibrated, operated, and maintained according to the vendor's specifications at all times the control device is in use.

47.5 Test Methods and Procedures.

47.5.1 The VOC content of each ink, the alcohol content of each fountain solution, and the efficiency of each capture system and control device shall be determined by the applicable test methods and procedures specified in Appendix A through Appendix D of this regulation to establish the records required under 47.6 of this regulation.

47.5.2 To demonstrate compliance with the emission control requirements of 47.0 of this regulation, the affected facility affected by 47.0 of this regulation shall be run at maximum operating conditions and flow rates during any emission testing.

47.5.3 Emission tests for facilities using an add-on dryer exhaust control device shall include an initial test when the control device is installed and operating in operation that demonstrates compliance with either the 90% (by weight) reduction or the 20 ppmv emission limit 47.3.1 of this regulation.

47.5.4 To determine compliance with 47.3.2 of this regulation, the owner or operator of an offset lithographic printing facility shall perform the following procedures:

47.5.4.1 A sample shall be taken of the fountain solution (as used) from the fountain tray or reservoir that contains a fresh batch of fountain solution (after mixing), for each unit or centralized reservoir, to determine the alcohol content of the fountain solution in accordance with 47.3.2.1 through 47.3.2.34 of this regulation, before the fountain solution is used.

47.5.4.2 A direct measurement of the alcohol content of the fountain solution sample or samples shall be performed in accordance with the method specified in Appendix L of this regulation.

47.5.4.3 Alternatively, a sample of the fountain solution (as used) may be taken from the fountain tray or reservoir of fountain solution during use and measured with a hydrometer or refractometer that has been standardized with tests performed in accordance with 47.5.4.1 and 47.5.4.2 of this regulation. The unit shall be considered in compliance with 47.3.2.1 through 47.3.2.34 of this regulation if the refractometer or hydrometer measurement is less than or equal to the measurement obtained by the method specified in Appendix L of this regulation plus 10%.

47.5.4.4 The VOC content of a fountain solution containing alcohol substitutes or non-alcohol additives shall be established with proper recordkeeping and the manufacturer's laboratory analysis technical information of the VOC content of the concentrated alcohol substitute and included in facility records. Records shall include the amount of concentrated substitute added per quantity of fountain water; the date and time of preparation if the fountain solution is mixed as a batch; and the calculated VOC content of the final solution to fulfill the requirements listed in 47.3.2.4 of this regulation.

47.5.5 To determine compliance with 47.3.2.1.1.2 and 47.3.2.3.2 of this regulation, an owner or operator of an offset lithographic printing facility shall use a thermometer or other temperature detection device capable of reading to 0.28°C (0.5°F) accuracy to ensure that a refrigerated fountain solution containing alcohol is below 15.65°C (60°F) at all times.

46.5.6 To determine compliance with 47.3.3 of this regulation, an owner or operator of an offset lithographic printing press or a letterpress printing press shall:

47.5.6.1 Take a sample of the cleaning solution (as used) to demonstrate compliance with the cleaning solution VOC content limitations listed in 47.3.3 of this regulation. If the cleaning solution is used as received from the supplier without dilution or alteration, the manufacturer's technical information may be used to demonstrate compliance.

47.5.6.2 Use the method specified in Appendix L of this regulation to determine the VOC content of the cleaning solution (as used). Alternatively, the VOC content and VOC partial pressure of the cleaning solution may be established using the manufacturer's technical data. If the cleaning solution is prepared through the dilution of concentrated materials, the blending ratio and VOC content of the concentrate may be used to determine the "as used" VOC content of the cleaning solution.

47.6 Recordkeeping and Reporting.

47.6.1 Requirements for Sources Below Threshold Emission Limit. Any owner or operator of any offset lithography printing press facility, any letterpress printing facility, or any facility with both offset lithographic and letterpress printing operations, that emits less than the threshold limit according to 47.1 of this regulation shall comply with the following requirements:

47.6.1.1 Initial Certification. Within six months after April 11, 2011, or upon initial startup of a new printing press, Tthe owner or operator shall certify to the Department that the facility emits less than the threshold limit according to 47.1 of this regulation. Such certification shall include the following information:

47.6.1.1.1 The name and location of the facility.

47.6.1.1.2 The address and telephone number of the person responsible for the facility.

47.6.1.1.3 A declaration that the facility is not subject to the requirements of 47.0 of this regulation because of the criteria listed in 47.1 of this regulation.

47.6.1.1.4 The calculations demonstrating that total actual VOC emissions from all offset lithographic and letterpress printing presses at the facility are and will be less than 6.8 kg (15 lb) per day before the application of capture systems and control devices.

47.6.1.1.5 A description of the instrument or method by which the owner or operator accurately measured or calculated the volume of ink applied and the amount that can potentially be applied each year on each printing press.

47.6.1.2 Recordkeeping. On and after April 11, 2011, Tthe owner or operator shall collect and record all of the following information each year for each offset lithographic printing press and each letterpress printing press and maintain the information at the facility for a period of five years:

47.6.1.2.1 The name and identification number of each ink, as applied, each year on each printing press.

47.6.1.2.2 The weight of VOC per volume of coating solids and the volume of solids of each ink, as applied, each year on each printing press.

47.6.1.2.32 The total actual VOC emissions as calculated in 47.6.1.1.4 of this regulation using the VOC content for that year.

47.6.1.3 Reporting. On and after April 11, 2011, Upon promulgation of 47.0 of this regulation, any record showing that total actual emissions of VOCs from all offset lithographic printing presses and all letterpress printing presses exceed 6.8 kg (15 lb) per day before the application of capture systems and control devices shall be reported by sending a copy of the record to the Department within 45 calendar days after the exceedance occurs. This requirement is in addition to any other State of Delaware exceedance reporting requirements.

47.6.2 Requirements for Sources Above Threshold Emission Limit. Any owner or operator of any offset lithography printing press facility, or any letterpress printing facility, or any facility with both offset lithographic and letterpress printing operations, that emits greater than the threshold limit according to 47.1 of this regulation shall comply with the following requirements:

47.6.2.1 Initial Certification. Within six months after April 11, 2011, or upon initial startup of a new printing press, Tthe owner or operator shall certify to the Department that the facility emits greater than the threshold limit according to 47.1 of this regulation. Such certification shall include the following information:

47.6.2.1.1 The name and location of the facility.

47.6.2.1.2 The address and telephone number of the person responsible for the facility.

47.6.2.1.3 The calculations demonstrating that total actual VOC emissions from all offset lithographic printing presses aspects of printing operations at the facility are and shall be greater than 15 lb (6.8 kg) per day before the application of capture systems and control devices.

47.6.2.1.4 A description of the instrument or method by which the owner or operator accurately measured or calculated the volume of ink applied and the amount that can potentially be applied each year on each printing press.

47.6.2.2 Recordkeeping. On and after April 11, 2011, Tthe owner or operator shall collect and record all of the following information each year for each offset lithographic printing press and each letterpress printing press and maintain the information at the facility for a period of five years:

47.6.2.2.1 The name and identification number of each ink, as applied, each year on each printing press.

47.6.2.2.2 The weight of VOCs per volume of coating solids and the volume of solids of each ink, as applied, each year on each printing press.

47.6.2.2.3 The total actual VOC emissions as calculated in 47.6.1.1.4 47.6.2.1.3 of this regulation using the VOC content for that year.

47.6.3 Requirements for Sources Using an Add-On Dryer Exhaust Control Device.

47.6.3.1 Within six months after April 11, 2011, or upon initial startup of a new printing press, Tthe owner or operator of a heatset offset lithographic printing press, or a heatset letterpress printing press, shall install, calibrate, maintain, and operate a temperature monitoring device, according to the manufacturer's instructions, at the outlet of the control device or at a location approved by the Department [and the EPA]. The monitoring temperature shall be set during the testing required to certify compliance with the requirements of 47.4 of this regulation. Monitoring shall be performed only when the unit is operational.

47.6.3.2 The temperature monitoring device shall be equipped with a continuous recorder and shall have an accuracy of 0.28°C (0.5°F).

47.6.3.3 The dryer pressure shall be maintained lower than the press room area pressure such that air flows into the dryer at all times when the press is operating. A 100% emissions capture efficiency for the dryer shall be demonstrated using an air flow direction measuring device.

47.6.4 Requirements for Monitoring Fountain Solution VOC Concentration. On and after April 11, 2011, Tthe alcohol concentration in the fountain solution shall be monitored to provide data that can be correlated to the amount of material used when the fountain solution complies with the limits listed in 47.3.2.1 through 47.3.2.43 of this regulation. One of the following methods shall be used to frequently measure the concentration of alcohol in the fountain solution:

47.6.4.1 The owner or operator of any offset lithographic printing press shall monitor the alcohol concentration of the fountain solution with a refractometer that is corrected for temperature at least once per 8-hour shift or once per batch, whichever is longer. The refractometer shall have a visual, analog, or digital readout with an accuracy of 0.5%. A standard solution shall be used to calibrate the refractometer for the type of alcohol used in the fountain. Alternatively, the refractometer shall be standardized with measurements performed to determine compliance, according to the procedures described in 47.5.4.1 and 47.5.4.2 of this regulation.

47.6.4.2 Alternatively, the owner or operator of any offset lithographic printing press shall monitor the alcohol concentration of the fountain solution with a hydrometer equipped with a temperature correction at least once per eight-hour shift or once per batch, whichever is longer. The hydrometer shall have a visual, analog, or digital readout with an accuracy of 0.5%. A standard solution shall be used to calibrate the hydrometer for the type of alcohol used in the fountain. Alternatively, the hydrometer shall be standardized with measurements performed to determine compliance, according to the procedures described in 47.5.4.1 and 47.5.4.2 of this regulation.

47.6.4.3 The VOC content of the fountain solution may be monitored with a conductivity meter if it is determined that a refractometer or hydrometer cannot be used for the type of VOCs in the fountain solution. The conductivity meter reading for the fountain solution shall be referenced to the conductivity of the incoming water.

47.6.4.4 If, through recordkeeping for a period of 6 months or more, the printing process is shown to consistently meet the requirements in 47.3.2.4 and 47.5.4 of this regulation, the monitoring requirement may be waived or extended to a longer period of time upon prior approval by the Department.

47.6.5 Requirements for Monitoring Fountain Solution Temperature. On and after April 11, 2011:

47.6.5.1 The owner or operator of any offset lithographic printing press using refrigeration equipment on the fountain solution shall install, maintain, and continuously operate a temperature monitor of the fountain solution reservoir.

47.6.5.2 The temperature monitor shall be attached to a continuous recording device such as a strip chart, recorder, or computer.

47.6.6 Requirements for Monitoring Cleaning Solution. On and after April 11, 2011, Ffor any offset lithographic printing press or any letterpress printing press with continuous cleaning equipment, flow meters shall be used to monitor the water and cleaning solution flow rates. The flow meters shall be calibrated so that the VOC content of the mixed solution is accurately measured to fulfill the requirements of 47.3.3 of this regulation.

47.6.7 Requirements for Monitoring Other Key Parameters. On and after April 11, 2011, Tthe owner or operator of any offset lithographic printing press or any letterpress printing press shall record daily, and make available to the Department within 45 calendar days upon the Department’s verbal or written request, the following key parameters:

47.6.7.1 The type of control device operating on the any heatset offset lithographic printing press or any heatset letterpress printing press and the operating parameters specified in [47.5.3 47.3.1] of this regulation.

47.6.7.2 The [equipment operating] standard selected to comply with the requirements listed in 47.3.2.1 through 47.3.2.43 and 47.3.3 of this regulation.

47.6.7.3 The VOC content of the fountain solutions and cleaning solutions, to comply with the requirements listed in 47.5.4, 47.6.4, and 47.6.6 of this regulation.

47.6.7.4 The temperature of the fountain solution, to comply with the requirements listed in 47.6.5 of this regulation, if applicable.

47.6.7.5 For manual cleaning methods, the amount of cleaning solution and the amount of water added per batch of cleaning solution mixed.

47.6.7.6 For automatic cleaning methods, the flow rates of water and cleaning solution concentrate, as specified in 47.6.6 of this regulation.

47.6.7.7 Corrective actions taken when exceedances of any parameters monitored according to the requirements of 47.4 or 47.5 of this regulation, occur.