04/04/1998

Title III of the Clean Air Act Amendments of November 15, 1990 revised Section 112 of the 1970 Clean Air Act that addressed hazardous air pollutants (HAPs) and changed the way that these pollutants were to be regulated. Title III identified the specific HAPs and established the regulatory approach that the U.S. Environmental Protection Agency (EPA) would take to control their emissions from stationary sources.

The EPA is initially required to promulgate emission standards that are based on the maximum achievable control technology (MACT) for categories or subcategories of sources according to a Congress-mandated schedule. Within eight years of promulgating these MACT-based standards, the EPA is required to address the remaining or residual risk by promulgating, if needed, standards necessary to provide an ample margin of safety to protect public health or to prevent an adverse environmental effect. The initial MACT-based regulations are at 40 CFR Part 63.

The Department is adopting these regulations in response to 7 Del.C., Ch 60.

09/11/1999

3.1 Applicability.

3.1.1 General.

3.1.1.1 Terms used throughout this regulation are defined in 4.2 of this regulation or in the Clean Air Act Amendments of 1990 (the Act), except that individual subparts of 40 CFR Part 63 or individual sections of this regulation may include specific definitions in addition to or that supersede definitions in 4.2 of this regulation.

3.1.1.2 This regulation contains emission standards for hazardous air pollutants initially established pursuant to Section 112 of the Act as amended November 15, 1990. These standards regulate specific categories of stationary sources that emit (or have the potential to emit) one or more hazardous air pollutants listed in 40 CFR Part 63 pursuant to Section 112(b) of the Act. This section explains the applicability of such standards to sources affected by them. The standards in 40 CFR Part 63 or this regulation are independent of NESHAP contained in 40 CFR Part 61 or 7 DE Admin. Code 1121 of the State of Delaware “Regulations Governing the Control of Air Pollution.” The NESHAP in Part 61 promulgated by signature of the Administrator before November 15, 1990 (i.e., the date of enactment of the Clean Air Act Amendments of 1990) remain in effect until they are amended, if appropriate, and added to 40 CFR Part 63. The standards in 7 DE Admin. Code 1121 remain in effect.

3.1.1.3 No emission standard or other requirement established under this regulation shall be interpreted, construed, or applied to diminish or replace the requirements of a more stringent emission limitation or other applicable requirement established by the Administrator pursuant to other authority of the Act (Section 111, Part C or D or any other authority of the Act), or a standard or other applicable requirement issued by the Department. The Department may specify in a specific standard under this regulation that facilities subject to other provisions under the Act need only comply with the provisions of that standard.

3.1.1.4 General provisions applicability to relevant standards.

3.1.1.4.1 Each relevant standard in 40 CFR Part 63 or this regulation shall identify explicitly whether each provision in 3.0 of this regulation is or is not included in such relevant standard.

3.1.1.4.2 If a relevant standard in 40 CFR Part 63 or this regulation incorporates the requirements of 40 CFR Part 60, Part 61 or Part 63 standard, the relevant standard shall identify explicitly the applicable general provisions (i.e. Subpart A requirements) of each corresponding Part 60, Part 61, or Part 63 standard or the applicable requirements in 3.0 of this regulation.

3.1.1.4.3 The General Provisions in 3.0 of this regulation do not apply to regulations developed pursuant to Section 112(r) of the Act, unless otherwise specified in those regulations.

3.1.1.5 [Reserved]

3.1.1.6 To obtain the most current list of categories of sources to be regulated under Section 112 of the Act, or to obtain the most recent regulation promulgation schedule established pursuant to Section 112(e) of the Act, contact the Office of the Director, Emission Standards Division, Office of Air Quality Planning and Standards, U.S. EPA (MD-13), Research Triangle Park, North Carolina 27711.

3.1.1.7 [Reserved]

3.1.1.8 [Reserved]

3.1.1.9 [Reserved]

3.1.1.10 For the purposes of this regulation, time periods specified in days shall be measured in calendar days, even if the word “calendar” is absent, unless otherwise specified in an applicable requirement.

3.1.1.11 For the purposes of this regulation, if an explicit postmark deadline is not specified in an applicable requirement for the submittal of a notification, application, test plan, report, or other written communication to the Administrator and the Department, the owner or operator shall postmark the submittal on or before the number of days specified in the applicable requirement. For example, if a notification must be submitted 15 days before a particular event is scheduled to take place, the notification shall be postmarked on or before 15 days preceding the event; likewise, if a notification must be submitted 15 days after a particular event takes place, the notification shall be postmarked on or before 15 days following the end of the event. The use of reliable non‑Government mail carriers that provide indications of verifiable delivery of information required to be submitted to the Administrator and the Department, similar to the postmark provided by the U.S. Postal Service, or alternative means of delivery agreed to by the Department, is acceptable.

3.1.1.12 Notwithstanding time periods or postmark deadlines specified in 40 CFR Part 63 or this regulation for the submittal of information to the Administrator or the Department by an owner or operator, or the review of such information by the Administrator or the Department, such time periods or deadlines may be changed by mutual agreement between the owner or operator and the Administrator or the Department. Procedures governing the implementation of this provision are specified in 3.9.9 of this regulation.

3.1.1.13 [Reserved]

3.1.1.14 [Reserved]

3.1.2 Initial applicability determination for this regulation.

3.1.2.1 The provisions of this regulation apply to the owner or operator of any stationary source that-

3.1.2.1.1 Emits or has the potential to emit any hazardous air pollutant listed in or pursuant to Section 112(b) of the Act and

3.1.2.1.2 Is subject to any standard, limitation, prohibition, or other federally enforceable requirement established pursuant to 40 CFR Part 63 or this regulation.

3.1.2.2 In addition to complying with the provisions of this regulation, the owner or operator of any such source may be required to obtain, revise or amend permits issued to stationary sources by the Department. For more information about obtaining permits, see 7 DE Admin. Codes 1102, 1125 and 1130 of the State of Delaware “Regulations Governing the Control of Air Pollution.”

3.1.2.3 An owner or operator of a stationary source who is in the relevant source category and who determines that the source is not subject to a relevant standard or other requirement established under 40 CFR Part 63 or this regulation shall keep a record as specified in 3.10.2.3 of this regulation.

3.1.3 Applicability of this regulation after a relevant standard has been set under 40 CFR Part 63 or this regulation.

3.1.3.1 If a relevant standard has been established under 40 CFR Part 63 or this regulation, the owner or operator of an affected source shall comply with the provisions of that standard and of 3.0 of this regulation as provided in 3.1.1.4 of this regulation.

3.1.3.2 Except as provided in 3.10.2.3 of this regulation, if a relevant standard has been established under 40 CFR Part 63 or this regulation, the owner or operator of an affected source may be required to obtain a Title V permit from the Department. Emission standards promulgated in 40 CFR Part 63 for area sources pursuant to Section 112(c)(3) of the Act or in this regulation will specify what the permitting requirements will be for area sources affected by such a standard.

3.1.3.3 [Reserved]

3.1.3.4 [Reserved]

3.1.3.5 If an area source that otherwise would be subject to an emission standard or other requirement established under 40 CFR Part 63 or this regulation if it were a major source subsequently increases its emissions of hazardous air pollutants (or its potential to emit hazardous air pollutants) such that the source is a major source that is subject to the emission standard or other requirement, such source also shall be subject to the notification requirements in 3.0 of this regulation.

3.1.4 [Reserved]

3.1.5 If the Administrator promulgates an emission standard under Section 112(d) or (h) of the Act that is applicable to a source subject to an emission limitation by permit established under Section 112(j) (of the Act) requirements in 5.12 though 5.18 of this regulation, and the requirements under that Section 112(j) emission limitation are substantially as effective as the promulgated emission standard, the owner or operator may request the Department to revise the source’s Title V permit to reflect that the emission limitation in the permit satisfies the requirements of the promulgated emission standard. The process by which the Department determines whether the Section 112(j) emission limitation is substantially as effective as the promulgated emission standard shall include, consistent with 7 DE Admin. Code 1130, the opportunity for full public, EPA, and affected State review (including the opportunity for EPA’s objection) prior to the permit revision being finalized. A negative determination by the Department constitutes final action for purposes of review and appeal under 7 DE Admin. Code 1130.

3.2 Definitions.

The terms used in this regulation are defined in the Act or in 3.2 of this regulation as follows:

“Act” means the Clean Air Act (42 U.S.C. 7401 et seq.).

“Actual emissions”, for the purpose of granting a compliance extension for an early reduction of hazardous air pollutants, mean the actual rate of emissions of a pollutant, but does not include excess emissions from a malfunction, or startups and shutdowns associated with a malfunction. Actual emissions shall be calculated using the source’s actual operating rates, and types of materials processed, stored, or combusted during the selected time period.

“Administrator” means the Administrator of the United States Environmental Protection Agency.

“Affected source”, for the purposes of this regulation, means the collection of equipment, activities, or both within a single contiguous area and under common control that is included in a Section 112(c) (of the Act) source category or subcategory for which a Section 112(d) (of the Act) standard or other relevant standard is established pursuant to Section 112 of the Act. Each relevant standard will define the “affected source,” as defined in 3.2 of this regulation unless a different definition is warranted based on a published justification as to why this definition would result in significant administrative, practical, or implementation problems and why the different definition would resolve those problems. The term “affected source,” as used in this regulation, is separate and distinct from any other use of that term in EPA regulations such as those implementing Title IV of the Act. Affected source may be defined differently for 40 CFR Part 63 and this regulation than affected facility and stationary source in 40 CFR Parts 60 and 61 and 7 DE Admin. Codes 1120 and 1121 of the State of Delaware “Regulation Governing the Control of Air Pollution”, respectively. This definition of “affected source,” and the procedures for adopting an alternative definition of “affected source,” shall apply to each Section 112(d) standard for which the initial proposed rule is signed by the Administrator after June 30, 2002.

“Alternative emission limitation” means conditions established pursuant to Sections 112(i)(5) or 112(i)(6) of the Act by the Department.

“Alternative emission standard” means an alternative means of emission limitation that, after notice and opportunity for public comment, has been demonstrated by an owner or operator to the Administrator’s satisfaction to achieve a reduction in emissions of any air pollutant at least equivalent to the reduction in emissions of such pollutant achieved under a relevant design, equipment, work practice, or operational emission standard, or combination thereof, established under 40 CFR Part 63 pursuant to Section 112(h) of the Act.

“Alternative test method” means any method of sampling and analyzing for an air pollutant that is not a test method in Chapter I of Title 40 and that has been demonstrated to the Administrator’s satisfaction, using Method 301 in Appendix A of 40 CFR Part 63, to produce results adequate for the Administrator’s determination that it may be used in place of a test method specified in 40 CFR Part 63 or this regulation.

“Approved permit program” means the permit program established under 7 DE Admin. Code 1130.

“Area source” means any stationary source of hazardous air pollutants that is not a major source as defined in this regulation.

“Commenced” means, with respect to construction or reconstruction of an affected source, that an owner or operator has undertaken a continuous program of construction or reconstruction or that an owner or operator has entered into a contractual obligation to undertake and complete, within a reasonable time, a continuous program of construction or reconstruction.

“Compliance date” means the date by which an affected source is required to be in compliance with a relevant standard, limitation, prohibition, or any federally enforceable requirement established by the Administrator or the Department pursuant to Section 112 of the Act.

“Compliance schedule” means:

“Construction” means the on-site fabrication, erection, or installation of an affected source. Construction does not include the removal of all equipment comprising an affected source from an existing location and reinstallation of such equipment at a new location. The owner or operator of an existing affected source that is relocated may elect not to reinstall minor ancillary equipment including, but not limited to, piping, ductwork, and valves. However, removal and reinstallation of an affected source will be construed as reconstruction if it satisfies the criteria for reconstruction as defined in 3.2 of this regulation. The costs of replacing minor ancillary equipment shall be considered in determining whether the existing affected source is reconstructed.

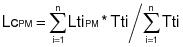

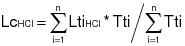

“Continuous emission monitoring system” (CEMS) means the total equipment that may be required to meet the data acquisition and availability requirements of 40 CFR Part 63 or this regulation, used to sample, condition (if applicable), analyze, and provide a record of emissions.

“Continuous monitoring system” (CMS) is a comprehensive term that may include, but is not limited to, continuous emission monitoring systems, continuous opacity monitoring systems, continuous parameter monitoring systems, or other manual or automatic monitoring that is used for demonstrating compliance with an applicable regulation on a continuous basis as defined by the regulation.

“Continuous opacity monitoring system” (COMS) means a continuous monitoring system that measures the opacity of emissions.

“Continuous parameter monitoring system” (CPMS) means the total equipment that may be required to meet the data acquisition and availability requirements of 40 CFR Part 63 or this regulation, used to sample, condition (if applicable), analyze, and provide a record of process or control system parameters.

“Department” means the Department of Natural Resources and Environmental Control as defined in 29 Del.C., Ch 80, as amended.

“Effective date” means:

“Emission standard” means a national standard, limitation, prohibition, or other regulation promulgated in a subpart of 40 CFR Part 63 pursuant to Sections 112(d), 112(h), or 112(f) of the Act or a standard, limitation, prohibition, or other regulation promulgated in a section of this regulation.

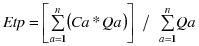

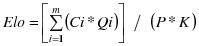

“Emissions averaging” is a way to comply with the emission limitations specified in a relevant standard, whereby an affected source, if allowed under a subpart of 40 CFR Part 63 or a section of this regulation, may create emission credits by reducing emissions from specific points to a level below that required by the relevant standard, and those credits are used to offset emissions from points that are not controlled to the level required by the relevant standard.

“EPA” means the United States Environmental Protection Agency.

“Equivalent emission limitation” means any maximum achievable control technology emission limitation or requirements which are applicable to a major source of hazardous air pollutants and are adopted by the Department on a case‑by‑case basis, pursuant to Section 112(g) or Section 112(j) (of the Act) requirements in 3.0 of this regulation.

“Excess emissions and continuous monitoring system performance report” is a report that must be submitted periodically by an affected source in order to provide data on its compliance with relevant emission limits, operating parameters, and the performance of its CPMS.

“Existing source” means any affected source that is not a new source.

“Federally enforceable” means all limitations and conditions that are enforceable by the Administrator and citizens under the Act or that are enforceable under other statutes administered by the Administrator. Examples of federally enforceable limitations and conditions include, but are not limited to:

“Fixed capital cost” means the capital needed to provide all the depreciable components of an existing source.

“Fugitive emissions” mean those emissions from a stationary source that could not reasonably pass through a stack, chimney, vent, or other functionally equivalent opening. Under Section 112 of the Act, all fugitive emissions are to be considered in determining whether a stationary source is a major source.

“Hazardous air pollutant” means any air pollutant listed in or pursuant to Section 112(b) of the Act.

“Intermediate change to monitoring” means a modification to federally required monitoring involving “proven technology” (generally accepted by the scientific community as equivalent or better) that is applied on a site-specific basis and that may have the potential to decrease the stringency of the associated emission limitation or standard. Though site-specific, an intermediate change may set a national precedent for a source category and may ultimately result in a revision to the federally required monitoring. Examples of intermediate changes to monitoring include, but are not limited to:

“Intermediate change to test method” means a within-method modification to a federally enforceable test method involving “proven technology” (generally accepted by the scientific community as equivalent or better) that is applied on a site-specific basis and that may have the potential to decrease the stringency of the associated emission limitation or standard. Though site-specific, an intermediate change may set a national precedent for a source category and may ultimately result in a revision to the federally enforceable test method. In order to be approved, an intermediate change shall be validated according to Method 301 in Appendix A of 40 CFR Part 63, to demonstrate that it provides equal or improved accuracy and precision. Examples of intermediate changes to a test method include, but are not limited to:

|

•

|

“Combining” a federally required method with another proven method for application to processes emitting multiple pollutants.

|

“Issuance of a Title V permit” will occur in accordance with the requirements of 7 DE Admin. Code 1130.

“Major change to monitoring” means a modification to federally required monitoring that uses “unproven technology or procedures” (not generally accepted by the scientific community) or is an entirely new method (sometimes necessary when the required monitoring is unsuitable). A major change to monitoring may be site-specific or may apply to one or more source categories and will almost always set a national precedent. Examples of major changes to monitoring include, but are not limited to:

“Major change to test method” means a modification to a federally enforceable test method that uses “unproven technology or procedures” (not generally accepted by the scientific community) or is an entirely new method (sometimes necessary when the required test method is unsuitable). A major change to a test method may be site-specific, or may apply to one or more sources or source categories, and will almost always set a national precedent. In order to be approved, a major change shall be validated according to Method 301 in Appendix A of 40 CFR Part 63. Examples of major changes to a test method include, but are not limited to:

“Major source” means any stationary source or group of stationary sources located within a contiguous area and under common control that emits or has the potential to emit considering controls, in the aggregate, 10 tons per year or more of any hazardous air pollutant or 25 tons per year or more of any combination of hazardous air pollutants, unless the Administrator establishes a lesser quantity, or in the case of radionuclides, different criteria from those specified in this sentence.

“Malfunction” means any sudden, infrequent, and not reasonably preventable failure of air pollution control and monitoring equipment, process equipment, or a process to operate in a normal or usual manner which causes, or has the potential to cause, the emission limitations in an applicable standard to be exceeded. Failures that are caused in part by poor maintenance or careless operation are not malfunctions.

“Minor change to monitoring” means:

“Minor change to test method” means:

“Monitoring” means the collection and use of measurement data or other information to control the operation of a process or pollution control device or to verify a work practice standard relative to assuring compliance with applicable requirements. Monitoring is composed of four elements:

|

•

|

Indicators of performance--the parameter or parameters you measure or observe for demonstrating proper operation of the pollution control measures or compliance with the applicable emissions limitation or standard. Indicators of performance may include direct or predicted emissions measurements (including opacity), operational parametric values that correspond to process or control device (and capture system) efficiencies or emissions rates, and recorded findings of inspection of work practice activities, materials tracking, or design characteristics. Indicators may be expressed as a single maximum or minimum value, a function of process variables (for example, within a range of pressure drops), a particular operational or work practice status (for example, a damper position, completion of a waste recovery task, materials tracking), or an interdependency between two or among more than two variables.

|

“New affected source” means the collection of equipment, activities, or both within a single contiguous area and under common control that is included in a Section 112(c) (of the Act) source category or subcategory that is subject to a Section 112(d) (of the Act) or other relevant standard for new sources. This definition of “new affected source,” and the criteria to be utilized in implementing it, shall apply to each Section 112(d) standard for which the initial proposed rule is signed by the Administrator after June 30, 2002. Each relevant standard will define the term “new affected source,” which will be the same as the “affected source” unless a different collection is warranted based on consideration of factors including:

“New source” means any affected source the construction or reconstruction of which is commenced after the Administrator first proposes a relevant emission standard under 40 CFR Part 63 establishing an emission standard applicable to such source.

“One-hour period”, unless otherwise defined in an applicable subpart of 40 CFR Part 63 or a section of this regulation, means any 60-minute period commencing on the hour.

“Opacity” means the degree to which emissions reduce the transmission of light and obscure the view of an object in the background. For COMS, opacity means the fraction of incident light that is attenuated by an optical medium.

“Owner or operator” means any person who owns, leases, operates, controls, or supervises a stationary source.

“Performance audit” means a procedure to analyze blind samples, the content of which is known by the Administrator or the Department, simultaneously with the analysis of performance test samples in order to provide a measure of test data quality.

“Performance evaluation” means the conduct of relative accuracy testing, calibration error testing, and other measurements used in validating the CMS data.

“Performance test” means the collection of data resulting from the execution of a test method (usually three emission test runs) used to demonstrate compliance with a relevant emission standard as specified in the performance test section of the relevant standard.

“Permit modification” means a change to a Title V permit as defined in 7 DE Admin. Code 1130.

“Permit program” means the comprehensive State operating permit system established under 7 DE Admin. Code 1130.

“Permit revision” means any permit modification or administrative permit amendment to a Title V permit as defined in 7 DE Admin. Code 1130.

“Permitting authority” means the Department.

“Potential to emit” means the maximum capacity of a stationary source to emit a pollutant under its physical and operational design. Any physical or operational limitation on the capacity of the stationary source to emit a pollutant, including air pollution control equipment and restrictions on hours of operation or on the type or amount of material combusted, stored, or processed, shall be treated as part of its design if the limitation or the effect it would have on emissions is federally enforceable.

“Reconstruction”, unless otherwise defined in a relevant standard, means the replacement of components of an affected or a previously nonaffected source to such an extent that:

“Regulation promulgation schedule” means the schedule for the promulgation of emission standards under 40 CFR Part 63, established by the Administrator pursuant to Section 112(e) of the Act and published in the Federal Register.

“Relevant standard” means:

|

•

|

An equivalent emission limitation established pursuant to Section 112 of the Act that applies to the collection of equipment, activities, or both regulated by such standard or limitation. A relevant standard may include or consist of a design, equipment, work practice, or operational requirement, or other measure, process, method, system, or technique (including prohibition of emissions) that the Administrator or the Department establishes for new or existing sources to which such standard or limitation applies. Every relevant standard established pursuant to Section 112 of the Act or in sections of this regulation includes 3.0 of this regulation, as provided by 4.1.1.4 of this regulation, and all applicable appendices of 40 CFR Part 63 or of other parts of Chapter I of Title 40 that are referenced in that standard or the sections of this regulation.

|

“Responsible official” means one of the following:

“Run” means one of a series of emission or other measurements needed to determine emissions for a representative operating period or cycle as specified in this regulation.

“Shutdown” means the cessation of operation of an affected source or portion of an affected source for any purpose.

“Six-minute period” means, with respect to opacity determinations, any one of the 10 equal parts of a one-hour period.

“Standard conditions” means a temperature of 293oK (68oF) and a pressure of 101.3 kilopascals (29.92 in. Hg).

“Startup” means the setting in operation of an affected source or portion of an affected source for any purpose.

“State” shall have its conventional meaning.

“Stationary source” means any building, structure, facility, or installation which emits or may emit any air pollutant.

“Test method” means the validated procedure for sampling, preparing, and analyzing for an air pollutant specified in a relevant standard as the performance test procedure. The test method may include methods described in an appendix of Chapter I of Title 40, test methods incorporated by reference in 40 CFR Part 63 or this regulation, or methods validated for an application through procedures in Method 301 in Appendix A of 40 CFR Part 63.

“Title V permit” means any permit issued, renewed, or revised pursuant to 7 DE Admin. Code 1130.

“Visible emission” means the observation of an emission of opacity or optical density above the threshold of vision.

“Working day” means any day on which State government offices are open for normal business. Saturdays, Sundays, and official State holidays are not working days.

3.3 Units and abbreviations.

Used in 40 CFR Part 63 and this regulation are abbreviations and symbols of units of measure. These are defined as follows:

3.3.1 System International (SI) units of measure:

A = ampere

g = gram

Hz = hertz

J = joule

oK = degree Kelvin

kg = kilogram

l = liter

m = meter

m3 = cubic meter

mg = milligram = 10-3 gram

ml = milliliter = 10-3 liter

mm = millimeter = 10-3 meter

Mg = megagram = 106 gram = metric ton

MJ = megajoule

mol = mole

N = Newton

ng = nanogram = 10-9 gram

nm = nanometer = 10-9 meter

Pa = pascal

s = second

V = volt

W = watt

= ohm

g = microgram = 10-6 gram

l = microliter = 10-6 liter

3.3.2 Other units of measure:

Btu = British thermal unit

oC = degree Celsius (centigrade)

cal = calorie

cfm = cubic feet per minute

cc = cubic centimeter

cu ft = cubic feet

d = day

dcf = dry cubic feet

dcm = dry cubic meter

dscf = dry cubic feet at standard conditions

dscm = dry cubic meter at standard conditions

eq = equivalent

oF = degree Fahrenheit

ft = feet

ft2 = square feet

ft3 = cubic feet

gal = gallon

gr = grain

g‑eq = gram equivalent

g‑mole = gram mole

hr = hour

in. = inch

in. H2O = inches of water

K = 1,000

kcal = kilocalorie

lb = pound

lpm = liter per minute

meq = milliequivalent

min = minute

MW = molecular weight

oz = ounces

ppb = parts per billion

ppbw = parts per billion by weight

ppbv = parts per billion by volume

ppm = parts per million

ppmw = parts per million by weight

ppmv = parts per million by volume

psia = pounds per square inch absolute

psig = pounds per square inch gage

oR = degree Rankine

scf = cubic feet at standard conditions

scfh = cubic feet at standard conditions per hour

scm = cubic meter at standard conditions

scmm = cubic meter at standard conditions per minute

sec = second

sq ft = square feet

std = at standard conditions

v/v = volume per volume

yd2 = square yards

yr = year

3.3.3 Miscellaneous:

act = actual

avg = average

I.D. = inside diameter

M = molar

N = normal

O.D. = outside diameter

% = percent

3.4 Prohibited activities and circumvention.

3.4.1 Prohibited activities.

3.4.1.1 No owner or operator subject to the provisions of this regulation shall operate any affected source in violation of the requirements of 40 CFR Part 63 or this regulation. Affected sources subject to and in compliance with either an extension of compliance or an exemption from compliance are not in violation of the requirements of 40 CFR Part 63 or this regulation. An extension of compliance can be granted by the Administrator under 40 CFR Part 63; by the Department under 3.6.9.1 of this regulation; or by the President under Section 112(i)(4) of the Act.

3.4.1.2 No owner or operator subject to the provisions of this regulation shall fail to keep records, notify, report, or revise reports as required under 40 CFR Part 63 or this regulation.

3.4.1.3 [Reserved]

3.4.1.4 [Reserved]

3.4.1.5 [Reserved]

3.4.2 Circumvention.

No owner or operator subject to the provisions of this regulation shall build, erect, install, or use any article, machine, equipment, or process to conceal an emission that would otherwise constitute noncompliance with a relevant standard. Such concealment includes, but is not limited to-

3.4.2.1 The use of diluents to achieve compliance with a relevant standard based on the concentration of a pollutant in the effluent discharged to the atmosphere and

3.4.2.2 The use of gaseous diluents to achieve compliance with a relevant standard for visible emissions.

3.4.2.3 [Reserved]

3.4.3 Fragmentation.

Fragmentation after November 15, 1990 which divides ownership of an operation, within the same facility among various owners where there is no real change in control, will not affect applicability. The owner and operator shall not use fragmentation or phasing of reconstruction activities (i.e., intentionally dividing reconstruction into multiple parts for purposes of avoiding new source requirements) to avoid becoming subject to new source requirements.

3.5 Preconstruction review and notification requirements.

3.5.1 Applicability.

3.5.1.1 The provisions of 3.5 of this regulation implement the preconstruction review requirements of Section 112(i)(1) of the Act. After the effective date of a relevant standard, promulgated pursuant to Section 112(d), (f), or (h) of the Act, under 40 CFR Part 63, the preconstruction review requirements in 3.5 apply to the owner or operator of new affected sources and reconstructed affected sources that are major-emitting as specified in 3.5 of this regulation. New and reconstructed affected sources that commence construction or reconstruction before the effective date of a relevant standard are not subject to the preconstruction review requirements specified in 3.5.2.3, 3.5.4, and 3.5.5 of this regulation.

3.5.1.2 The provisions of 3.5 of this regulation include notification requirements for new affected sources and reconstructed affected sources that are not major-emitting affected sources and that are or become subject to a relevant promulgated emission standard after the effective date of a relevant standard promulgated under 40 CFR Part 63.

3.5.2 Requirements for existing, newly constructed, and reconstructed sources.

3.5.2.1 A new affected source for which construction commences after proposal of a relevant standard is subject to relevant standards for new affected sources, including compliance dates. An affected source for which reconstruction commences after proposal of a relevant standard is subject to relevant standards for new sources, including compliance dates, irrespective of any change in emissions of hazardous air pollutants from that source.

3.5.2.2 [Reserved]

3.5.2.3 After the effective date of any relevant standard promulgated by the Administrator under 40 CFR Part 63, no person may, without obtaining written approval in advance from the Department in accordance with the procedures specified in 3.5.4 and 3.5.5 of this regulation, do any of the following:

3.5.2.3.1 Construct a new affected source that is major-emitting and subject to such standard;

3.5.2.3.2 Reconstruct an affected source that is major-emitting and subject to such standard; or

3.5.2.3.3 Reconstruct a source such that the source becomes an affected source that is major-emitting and subject to the standard.

3.5.2.4 After the effective date of any relevant standard promulgated by the Administrator under 40 CFR Part 63, an owner or operator who constructs a new affected source that is not major-emitting or reconstructs an affected source that is not major-emitting that is subject to such standard, or reconstructs a source such that the source becomes an affected source subject to the standard, shall notify the Department of the intended construction or reconstruction. The notification shall be submitted in accordance with the procedures in 3.9.2 of this regulation.

3.5.2.5 [Reserved]

3.5.2.6 After the effective date of any relevant standard promulgated by the Administrator under 40 CFR Part 63, equipment added (or a process change) to an affected source that is within the scope of the definition of affected source under the relevant standard shall be considered part of the affected source and subject to all provisions of the relevant standard established for that affected source.

3.5.3 [Reserved]

3.5.4 Application for approval of construction or reconstruction.

The provisions in 3.5.4 of this regulation implement Section 112(i)(1) of the Act.

3.5.4.1 General application requirements.

3.5.4.1.1 An owner or operator who is subject to the requirements in 3.5.2.3 of this regulation shall submit to the Department an application for approval of the construction or reconstruction. The application shall be submitted as soon as practicable before actual construction or reconstruction begins. The application for approval of construction or reconstruction may be used to fulfill the initial notification requirements in 3.9.2.5 of this regulation. The owner or operator may submit the application for approval well in advance of the date actual construction or reconstruction begins in order to ensure a timely review by the Department and that the planned date to begin will not be delayed.

3.5.4.1.2 A separate application shall be submitted for each construction or reconstruction. Each application for approval of construction or reconstruction shall include at a minimum:

3.5.4.1.2.1 The applicant’s name and address;

3.5.4.1.2.2 A notification of intention to construct a new major affected source or make any physical or operational change to a major affected source that may meet or has been determined to meet the criteria for a reconstruction, as defined in 3.2 of this regulation or in the relevant standard;

3.5.4.1.2.3 The address (i.e., physical location) or proposed address of the source;

3.5.4.1.2.4 An identification of the relevant standard that is the basis of the application;

3.5.4.1.2.5 The expected date of the beginning of actual construction or reconstruction;

3.5.4.1.2.6 The expected completion date of the construction or reconstruction;

3.5.4.1.2.7 The anticipated date of (initial) startup of the source;

3.5.4.1.2.8 The type and quantity of hazardous air pollutants emitted by the source, reported in units and averaging times and in accordance with the test methods specified in the relevant standard, or if actual emissions data are not yet available, an estimate of the type and quantity of hazardous air pollutants expected to be emitted by the source reported in units and averaging times specified in the relevant standard. The owner or operator may submit percent reduction information if a relevant standard is established in terms of percent reduction. However, operating parameters, such as flow rate, shall be included in the submission to the extent that they demonstrate performance and compliance; and

3.5.4.1.2.9 [Reserved]

3.5.4.1.2.10 Other information as specified in 3.5.4.2 and 3.5.4.3 of this regulation.

3.5.4.1.3 An owner or operator who submits estimates or preliminary information in place of the actual emissions data and analysis required in 3.5.4.1.2.8 and 3.5.4.2 of this regulation shall submit the actual, measured emissions data and other correct information as soon as available but no later than with the notification of compliance status required in 3.9.8 of this regulation (see 3.9.8.5 of this regulation).

3.5.4.2 Application for approval of construction

Each application for approval of construction shall include, in addition to the information required in 3.5.4.1.2 of this regulation, technical information describing the proposed nature, size, design, operating design capacity, and method of operation of the source, including an identification of each type of emission point for each type of hazardous air pollutant that is emitted (or could reasonably be anticipated to be emitted) and a description of the planned air pollution control system (equipment or method) for each emission point. The description of the equipment to be used for the control of emissions shall include each control device for each hazardous air pollutant and the estimated control efficiency (percent) for each control device. The description of the method to be used for the control of emissions shall include an estimated control efficiency (percent) for that method. Such technical information shall include calculations of emission estimates in sufficient detail to permit assessment of the validity of the calculations.

3.5.4.3 Application for approval of reconstruction.

Each application for approval of reconstruction shall include, in addition to the information required in 3.5.4.1.2 of this regulation

3.5.4.3.1 A brief description of the affected source and the components that are to be replaced;

3.5.4.3.2 A description of present and proposed emission control systems (i.e., equipment or methods). The description of the equipment to be used for the control of emissions shall include each control device for each hazardous air pollutant and the estimated control efficiency (percent) for each control device. The description of the method to be used for the control of emissions shall include an estimated control efficiency (percent) for that method. Such technical information shall include calculations of emission estimates in sufficient detail to permit assessment of the validity of the calculations;

3.5.4.3.3 An estimate of the fixed capital cost of the replacements and of constructing a comparable entirely new source;

3.5.4.3.4 The estimated life of the affected source after the replacements; and

3.5.4.3.5 A discussion of any economic or technical limitations the source may have in complying with relevant standards or other requirements after the proposed replacements. The discussion shall be sufficiently detailed to demonstrate to the Department’s satisfaction that the technical or economic limitations affect the source’s ability to comply with the relevant standard and how they do so.

3.5.4.3.6 If in the application for approval of reconstruction the owner or operator designates the affected source as a reconstructed source and declares that there are no economic or technical limitations to prevent the source from complying with all relevant standards or other requirements, the owner or operator need not submit the information required in 3.5.4.3.3 through 3.5.4.3.5 of this regulation.

3.5.4.4 Additional information

The Department may request additional relevant information after the submittal of an application for approval of construction or reconstruction.

3.5.5 Approval of construction or reconstruction.

3.5.5.1 Determination

3.5.5.1.1 If the Department determines that, if properly constructed, or reconstructed, and operated, a new or existing source for which an application under 3.5.4 of this regulation was submitted will not cause emissions in violation of the relevant standards and any other federally enforceable requirements, the Department will approve the construction or reconstruction.

3.5.5.1.2 In addition, in the case of reconstruction, the Department’s determination under 3.5.5 of this regulation will be based on:

3.5.5.1.2.1 The fixed capital cost of the replacements in comparison to the fixed capital cost that would be required to construct a comparable entirely new source;

3.5.5.1.2.2 The estimated life of the source after the replacements compared to the life of a comparable entirely new source;

3.5.5.1.2.3 The extent to which the components being replaced cause or contribute to the emissions from the source; and

3.5.5.1.2.4 Any economic or technical limitations on compliance with relevant standards that are inherent in the proposed replacements.

3.5.5.2 Notification

3.5.5.2.1 The Department will notify the owner or operator in writing of approval or intention to deny approval of construction or reconstruction within 60 calendar days after receipt of sufficient information to evaluate an application submitted under 3.5.4 of this regulation. The 60-day approval or denial period will begin after the owner or operator has been notified in writing that the owner or operator’s application is complete. The Department will notify the owner or operator in writing of the status of the owner or operator’s application, that is, whether the application contains sufficient information to make a determination, within 30 calendar days after receipt of the original application and within 30 calendar days after receipt of any supplementary information that is submitted.

3.5.5.2.2 When notifying the owner or operator that the owner or operator’s application is not complete, the Department will specify the information needed to complete the application and provide notice of opportunity for the applicant to present, in writing, within 30 calendar days after the owner or operator is notified of the incomplete application, additional information or arguments to the Department to enable further action on the application.

3.5.5.3 Before denying any application for approval of construction or reconstruction, the Department will notify the applicant of the Department’s intention to issue the denial together with--

3.5.5.3.1 Notice of the information and findings on which the intended denial is based and

3.5.5.3.2 Notice of opportunity for the applicant to present, in writing, within 30 calendar days after the owner or operator is notified of the intended denial, additional information or arguments to the Department to enable further action on the application.

3.5.5.4 A final determination to deny any application for approval will be in writing and will specify the grounds on which the denial is based. The final determination will be made within 60 calendar days of presentation of additional information or arguments (if the application is complete), or within 60 calendar days after the final date specified for presentation if no presentation is made.

3.5.5.5 Neither the submission of an application for approval nor the Department’s approval of construction or reconstruction shall--

3.5.5.5.1 Relieve an owner or operator of legal responsibility for compliance with any applicable provisions of 40 CFR Part 63 or this regulation or with any other applicable Federal, State, or local requirement, including, but not limited to the requirement to obtain construction permits under 7 DE Admin. Code 1102 or 1125, before commencing construction or reconstruction or

3.5.5.5.2 Prevent the Administrator from implementing or enforcing 40 CFR Part 63 or taking any other action under the Act or the Department from implementing or enforcing this regulation or taking any other action under 7 Del.C., Ch 60.

3.5.6 Approval of construction or reconstruction based on prior State preconstruction review.

3.5.6.1 Preconstruction review procedures under 7 DE Admin. Code 1102 or 1125, may be utilized for purposes of 3.0 of this regulation. The Department will approve an application for construction or reconstruction specified in 3.5.2.3 and 3.5.4 of this regulation if the owner or operator of a new affected source or reconstructed affected source, who is subject to such requirement meets the following condition:

3.5.6.1.1 The owner or operator of the new affected source or reconstructed affected source has undergone a preconstruction review and approval process and has received a federally enforceable construction permit that contains a finding that the source will meet the relevant promulgated emission standard, if the source is properly built and operated.

3.5.6.1.2 [Reserved]

3.5.6.1.3 [Reserved]

3.5.6.1.4 [Reserved]

3.5.6.2 The owner or operator shall submit to the Department the request for approval of construction or reconstruction under 3.5.6.2 of this regulation no later than the application deadline specified in 3.5.4.1 of this regulation (see also 3.9.2.2 of this regulation). The owner or operator shall include in the request information sufficient for the Department’s determination. The Department will evaluate the owner or operator’s request in accordance with the procedures specified in 3.5.5 of this regulation. The Department may request additional relevant information after the submittal of a request for approval of construction or reconstruction under 3.5.6.2 of this regulation.

3.6 Compliance with standards and maintenance requirements

3.6.1 Applicability.

3.6.1.1 The requirements in 3.6 of this regulation apply to the owner or operator of affected sources for which any relevant standard has been established pursuant to Section 112 of the Act and the applicability of such requirements is set out in accordance with 3.1.1.4 of this regulation unless--

3.6.1.1.1 The Administrator, under 40 CFR Part 63, or the Department, under 3.6.9 of this regulation, has granted an extension of compliance or

3.6.1.1.2 The President has granted an exemption from compliance with any relevant standard in accordance with Section 112(i)(4) of the Act.

3.6.1.2 If an area source that otherwise would be subject to an emission standard or other requirement established under 40 CFR Part 63 or this regulation if it were a major source subsequently increases its emissions of hazardous air pollutants (or its potential to emit hazardous air pollutants) such that the source is a major source, such source shall be subject to the relevant emission standard or other requirement.

3.6.2 Compliance dates for new and reconstructed sources

3.6.2.1 Except as specified in 2.6.2.3 and 3.6.2.4 of this regulation, the owner or operator of a new or reconstructed affected source for which construction or reconstruction commences after proposal of a relevant standard that has an initial startup before the effective date of a relevant standard established under 40 CFR Part 63 pursuant to Section 112(d), (f), or (h) of the Act shall comply with such standard not later than the standard’s effective date.

3.6.2.2 Except as specified in 3.6.2.3 and 3.6.2.4 of this regulation, the owner or operator of a new or reconstructed affected source that has an initial startup after the effective date of a relevant standard established under 40 CFR Part 63 pursuant to Section 112(d), (f), or (h) of the Act shall comply with such standard upon startup of the source.

3.6.2.3 The owner or operator of an affected source for which construction or reconstruction is commenced after the proposal date of a relevant standard established under 40 CFR Part 63 pursuant to Section 112(d), 112(f), or 112(h) of the Act but before the effective date (that is, promulgation) of such standard shall comply with the relevant emission standard not later than the date three years after the effective date if:

3.6.2.3.1 The promulgated standard (that is, the relevant standard) is more stringent than the proposed standard; for purposes of 3.6.2 of this regulation, a finding that controls or compliance methods are “more stringent” shall include control technologies or performance criteria and compliance or compliance assurance methods that are different but are substantially equivalent to those required by the promulgated rule, as determined by the Department and

3.6.2.3.2 The owner or operator complies with the standard as proposed during the three-year period immediately after the effective date.

3.6.2.4 The owner or operator of an affected source for which construction or reconstruction is commenced after the proposal date of a relevant standard established under 40 CFR Part 63 pursuant to Section 112(d) of the Act but before the proposal date of a relevant standard established pursuant to Section 112(f) of the Act shall not be required to comply with the Section 112(f) emission standard until the date 10 years after the date construction or reconstruction is commenced, except that, if the Section 112(f) standard is promulgated more than 10 years after construction or reconstruction is commenced, the owner or operator shall comply with the standard as provided in 3.6.2.1 and 3.6.2.2 of this regulation.

3.6.2.5 The owner or operator of a new source that is subject to the compliance requirements in 3.6.2.3 or 3.6.2.4 of this regulation shall notify the Department in accordance with 3.9.4 of this regulation.

3.6.2.6 [Reserved]

3.6.2.7 When an area source becomes a major source by the addition of equipment or operations that meet the definition of new affected source in the relevant standard, the portion of the existing facility that is a new affected source shall comply with all requirements of that standard applicable to new sources. The source owner or operator shall comply with the relevant standard upon startup.

3.6.3 Compliance dates for existing sources.

3.6.3.1 After the effective date of a relevant standard established under 40 CFR Part 63 pursuant to Section 112(d) or 112(h) of the Act, the owner or operator of an existing source shall comply with such standard by the compliance date established by the Administrator in the applicable subparts of 40 CFR Part 63. Except as otherwise provided for in Section 112 of the Act, in no case will the compliance date established for an existing source in an applicable subpart of 40 CFR Part 63 exceed three years after the effective date of such standard.

3.6.3.2 If an existing source is subject to a standard established under 40 CFR Part 63 pursuant to Section 112(f) of the Act, the owner or operator shall comply with the standard by the date 90 days after the standard’s effective date, or by the date specified in an extension granted to the source by the Administrator, under 40 CFR Part 63, or the Department, under 3.6.9.4.2 of this regulation, whichever is later.

3.6.3.3 [Reserved]

3.6.3.4 [Reserved]

3.6.3.5 Except as provided in 3.6.2.7 of this regulation, the owner or operator of an area source that increases its emissions of (or its potential to emit) hazardous air pollutants such that the source becomes a major source shall be subject to relevant standards for existing sources. Such sources shall comply by the date specified in the standards for existing area sources that become major sources. If no such compliance date is specified in the standards, the source shall have a period of time to comply with the relevant emission standard that is equivalent to the compliance period specified in the relevant standard for existing sources in existence at the time the standard becomes effective.

3.6.4 [Reserved]

3.6.5 Operation and maintenance requirements.

3.6.5.1 Operating and maintenance procedures.

3.6.5.1.1 At all times, including periods of startup, shutdown, or malfunction, the owner or operator shall operate and maintain any affected source, including associated air pollution control equipment and monitoring equipment, in a manner consistent with safety and good air pollution control practices for minimizing emissions. During a period of startup, shutdown, or malfunction, this general duty to minimize emissions requires that the owner or operator reduce emissions from the affected source to the greatest extent which is consistent with safety and good air pollution control practices. The general duty to minimize emissions during a period of startup, shutdown, or malfunction does not require the owner or operator to achieve emission levels that would be required by the applicable standard at other times if this is not consistent with safety and good air pollution control practices, nor does it require the owner or operator to make any further efforts to reduce emissions if levels required by the applicable standard have been achieved. Determination of whether such operation and maintenance procedures are being used will be based on information available to the Department which may include, but is not limited to, monitoring results, review of operation and maintenance procedures (including the startup, shutdown, and malfunction plan required in 3.6.5.3 of this regulation), review of operation and maintenance records, and inspection of the source.

3.6.5.1.2 Malfunctions shall be corrected as soon as practicable after their occurrence in accordance with the startup, shutdown, and malfunction plan required in 3.6.5.3 of this regulation. To the extent that an unexpected event arises during a startup, shutdown, or malfunction, an owner or operator shall comply by minimizing emissions during such a startup, shutdown, or malfunction event consistent with safety and good air pollution control practices.

3.6.5.1.3 Operation and maintenance requirements established pursuant to Section 112 of the Act or this regulation are enforceable independent of emissions limitations or other requirements in relevant standards.

3.6.5.2 [Reserved]

3.6.5.3 Startup, shutdown, and malfunction plan.

3.6.5.3.1 The owner or operator of an affected source shall develop and implement a written startup, shutdown, and malfunction plan that describes, in detail, procedures for operating and maintaining the source during periods of startup, shutdown, or malfunction, and a program of corrective action for malfunctioning process and air pollution control and monitoring equipment used to comply with the relevant standard. This plan shall be developed by the owner or operator by the source’s compliance date for that relevant standard. The purpose of the startup, shutdown, and malfunction plan is to-

3.6.5.3.1.1 Ensure that, at all times, the owner or operator operates and maintains each affected source, including associated air pollution control and monitoring equipment, in a manner which satisfies the general duty to minimize emissions established in 3.6.5.1.1 of this regulation;

3.6.5.3.1.2 Ensure that the owner or operator is prepared to correct malfunctions as soon as practicable after their occurrence in order to minimize excess emissions of hazardous air pollutants; and

3.6.5.3.1.3 Reduce the reporting burden associated with periods of startup, shutdown, or malfunction (including corrective action taken to restore malfunctioning process and air pollution control and monitoring equipment to its normal or usual manner of operation).

3.6.5.3.2 During periods of startup, shutdown, or malfunction, the owner or operator of an affected source shall operate and maintain such source (including associated air pollution control and monitoring equipment) in accordance with the procedures specified in the startup, shutdown, and malfunction plan developed under 3.6.5.3.1 of this regulation.

3.6.5.3.3 When actions taken by the owner or operator during a startup, shutdown, or malfunction (including actions taken to correct a malfunction) are consistent with the procedures specified in the affected source’s startup, shutdown, and malfunction plan, the owner or operator shall keep records for that event which demonstrate that the procedures specified in the plan were followed. These records may take the form of a “checklist,” or other effective form of recordkeeping that confirms conformance with the startup, shutdown, and malfunction plan for that event. In addition, the owner or operator shall keep records of these events as specified in 3.10.2 of this regulation, including records of the occurrence and duration of each startup, shutdown, or malfunction of operation and each malfunction of the air pollution control and monitoring equipment. Furthermore, the owner or operator shall confirm that actions taken during the relevant reporting period during periods of startup, shutdown, or malfunction were consistent with the affected source’s startup, shutdown and malfunction plan in the semiannual (or more frequent) startup, shutdown, and malfunction report required in 3.10.4.5 of this regulation.

3.6.5.3.4 If an action taken by the owner or operator during a startup, shutdown, or malfunction (including an action taken to correct a malfunction) is not consistent with the procedures specified in the affected source’s startup, shutdown, and malfunction plan, and the source exceeds any applicable emission limitation in the relevant emission standard, then the owner or operator shall record the actions taken for that event and shall report such actions within two working days after commencing actions inconsistent with the plan, followed by a letter within seven working days after the end of the event, in accordance with 3.10.4.5 of this regulation (unless the owner or operator makes alternative reporting arrangements, in advance, with the Department).

3.6.5.3.5 The owner or operator shall maintain at the affected source a current startup, shutdown, and malfunction plan and shall make the plan available upon request for inspection and copying by the Department. In addition, if the startup, shutdown, and malfunction plan is subsequently revised as provided in 3.6.5.3.8 of this regulation, the owner or operator shall maintain at the affected source each previous (i.e., superseded) version of the startup, shutdown, and malfunction plan, and shall make each such previous version available for inspection and copying by the Department for a period of five years after revision of the plan. If at any time after adoption of a startup, shutdown, and malfunction plan the affected source ceases operation or is otherwise no longer subject to the provisions of a relevant standard, the owner or operator shall retain a copy of the most recent plan for five years from the date the source ceases operation or is no longer subject to the relevant standard and shall make the plan available upon request for inspection and copying by the Department. The Department may at any time request in writing that the owner or operator submit a copy of any startup, shutdown, and malfunction plan (or a portion thereof) which is maintained at the affected source or in the possession of the owner or operator. Upon receipt of such a request, the owner or operator shall promptly submit a copy of the requested plan (or a portion thereof) to the Department. The Department shall request that the owner or operator submit a particular startup, shutdown, and malfunction plan (or a portion thereof) whenever a member of the public submits a specific and reasonable request to examine or to receive a copy of that plan or portion of a plan. The owner or operator may elect to submit the required copy of any startup, shutdown, and malfunction plan to the Department in an electronic format. If the owner or operator claims that any portion of such a startup, shutdown, and malfunction plan is confidential business information entitled to protection from disclosure under Section 114(c) of the Act, 40 CFR 2.301, 7 Del.C., Ch 60, §6014, or 29 Del.C., Ch 100, §10002(d), the material which is claimed as confidential shall be clearly designated in the submission.

3.6.5.3.6 To satisfy the requirements in 3.6 of this regulation to develop a startup, shutdown, and malfunction plan, the owner or operator may use the affected source’s standard operating procedures (SOP) manual, or an Occupational Safety and Health Administration (OSHA) or other plan, provided the alternative plans meet all the requirements in 3.6 of this regulation and are made available for inspection or submitted when requested by the Department.

3.6.5.3.7 Based on the results of a determination made under 3.6.5.1.1 of this regulation, the Department may require that an owner or operator of an affected source make changes to the startup, shutdown, and malfunction plan for that source. The Department shall require appropriate revisions to a startup, shutdown, and malfunction plan, if the Department finds that the plan:

3.6.5.3.7.1 Does not address a startup, shutdown, or malfunction event that has occurred;

3.6.5.3.7.2 Fails to provide for the operation of the source (including associated air pollution control and monitoring equipment) during a startup, shutdown, or malfunction event in a manner consistent with the general duty to minimize emissions established 3.6.5.1.1 of this regulation;

3.6.5.3.7.3 Does not provide adequate procedures for correcting malfunctioning process, air pollution control equipment, or monitoring equipment as quickly as practicable; or

3.6.5.3.7.4 Includes an event that does not meet the definitions of startup, shutdown, or malfunction listed in 3.2 of this regulation.

3.6.5.3.8 The owner or operator may periodically revise the startup, shutdown, and malfunction plan for the affected source as necessary to satisfy the requirements of a relevant standard or to reflect changes in equipment or procedures at the affected source. Unless the Department provides otherwise, the owner or operator may make such revisions to the startup, shutdown, and malfunction plan without prior approval by the Administrator or the Department. However, each such revision to a startup, shutdown, and malfunction plan shall be reported in the semiannual report required in 2.10.4.5 of this regulation. If the startup, shutdown, and malfunction plan fails to address or inadequately addresses an event that meets the characteristics of a malfunction but was not included in the startup, shutdown, and malfunction plan at the time the owner or operator developed the plan, the owner or operator shall revise the startup, shutdown, and malfunction plan within 45 days after the event to include detailed procedures for operating and maintaining the source during similar malfunction events and a program of corrective action for similar malfunctions of process or air pollution control and monitoring equipment. In the event that the owner or operator makes any revision to the startup, shutdown, and malfunction plan which alters the scope of the activities at the source which are deemed to be a startup, shutdown, or malfunction, or otherwise modifies the applicability of any emission limit, work practice requirement, or other requirement in a standard established under 40 CFR Part 63 or this regulation, the revised plan shall not take effect until after the owner or operator has provided a written notice describing the revision to the Department.

3.6.5.3.9 The Title V permit for an affected source shall require that the owner or operator adopt a startup, shutdown, and malfunction plan which conforms to the provisions of this regulation, and that the owner or operator operate and maintain the source in accordance with the procedures specified in the current startup, shutdown, and malfunction plan. However, any revisions made to the startup, shutdown, and malfunction plan in accordance with the procedures established by this regulation shall not be deemed to constitute permit revisions under 7 DE Admin. Code 1130. Moreover, none of the procedures specified by the startup, shutdown, and malfunction plan for an affected source shall be deemed to fall within the permit shield provision in Section 504(f) of the Act.

3.6.6 Compliance with non-opacity emission standards--

3.6.6.1 Applicability.

The non-opacity emission standards set forth in 40 CFR Part 63 or this regulation shall apply at all times except during periods of startup, shutdown, or malfunction, and as otherwise specified in an applicable subpart of 40 CFR Part 63 or section in this regulation. If a startup, shutdown, or malfunction of one portion of an affected source does not affect the ability of particular emission points within other portions of the affected source to comply with the non-opacity emission standards set forth in 40 CFR Part 63 or this regulation, then that emission point shall still be required to comply with the non-opacity emission standards and other applicable requirements.

3.6.6.2 Methods for determining compliance.

3.6.6.2.1 The Department will determine compliance with non-opacity emission standards in 40 CFR Part 63 or this regulation based on the results of performance tests conducted according to the procedures in 3.7 of this regulation, unless otherwise specified in an applicable subpart of 40 CFR Part 63 or section in this regulation.

3.6.6.2.2 The Department will determine compliance with non-opacity emission standards in 40 CFR Part 63 or this regulation by evaluation of an owner or operator’s conformance with operation and maintenance requirements, including the evaluation of monitoring data, as specified in 3.6.5 of this regulation and applicable subparts of 40 CFR Part 63 or sections in this regulation.

3.6.6.2.3 If an affected source conducts performance testing at startup to obtain an approved operating permit under 7 DE Admin. Codes 1102, 1125 or 1130, the results of such testing may be used to demonstrate compliance with a relevant standard if--

3.6.6.2.3.1 The performance test was conducted within a reasonable amount of time before an initial performance test is required to be conducted under the relevant standard;

3.6.6.2.3.2 The performance test was conducted under representative operating conditions for the source;

3.6.6.2.3.3 The performance test was conducted and the resulting data were reduced using EPA-approved test methods and procedures, as specified in 3.7.5 of this regulation; and

3.6.6.2.3.4 The performance test was appropriately quality-assured, as specified in 3.7.3 of this regulation.

3.6.6.2.4 The Department will determine compliance with design, equipment, work practice, or operational emission standards in 40 CFR Part 63 or this regulation by review of records, inspection of the source, and other procedures specified in applicable subparts of 40 CFR Part 63 or sections in this regulation.

3.6.6.2.5 The Department will determine compliance with design, equipment, work practice, or operational emission standards in 40 CFR Part 63 or this regulation by evaluation of an owner or operator’s conformance with operation and maintenance requirements, as specified in 3.6.5 of this regulation and applicable subparts of 40 CFR Part 63 or sections in this regulation.

3.6.6.3 Finding of compliance.

The Department will make a finding concerning an affected source’s compliance with a non-opacity emission standard, as specified in 3.6.6.1 and 3.6.6.2 of this regulation, upon obtaining all the compliance information required by the relevant standard (including the written reports of performance test results, monitoring results, and other information, if applicable), and information available to the Department pursuant to 3.6.5.1.1 of this regulation.

3.6.7 Use of an alternative non-opacity emission standard.

3.6.7.1 If, in the Administrator’s judgment, an owner or operator of an affected source has established that an alternative means of emission limitation will achieve a reduction in emissions of a hazardous air pollutant from an affected source at least equivalent to the reduction in emissions of that pollutant from that source achieved under any design, equipment, work practice, or operational emission standard, or combination thereof, established under 40 CFR Part 63 pursuant to Section 112(h) of the Act, the Administrator will publish in the Federal Register a notice permitting the use of the alternative emission standard for purposes of compliance with the promulgated standard. That Federal Register notice shall be published only after the public is notified and given the opportunity to comment. Such notice will restrict the permission to the stationary sources or categories of sources from which the alternative emission standard will achieve equivalent emission reductions. The Administrator will condition permission in such notice on requirements to assure the proper operation and maintenance of equipment and practices required for compliance with the alternative emission standard and other requirements, including appropriate quality assurance and quality control requirements, that are deemed necessary.

3.6.7.2 An owner or operator requesting permission under 3.6.7 of this regulation shall, unless otherwise specified in an applicable subpart, submit to the Administrator (with copy to the Department) a proposed test plan or the results of testing and monitoring in accordance with 3.7 and 3.8 of this regulation, a description of the procedures followed in testing or monitoring, and a description of pertinent conditions during testing or monitoring. Any testing or monitoring conducted to request permission to use an alternative non-opacity emission standard shall be appropriately quality assured and quality controlled, as specified in 3.7 and 3.8 of this regulation.

3.6.7.3 The Administrator may establish general procedures in an applicable subpart that accomplish the requirements 3.6.7.1 and 3.6.7.2 of this regulation.

3.6.8 Compliance with opacity and visible emission standards--

3.6.8.1 Applicability.

The opacity and visible emission standards set forth in this regulation shall apply at all times except during periods of startup, shutdown, or malfunction, and as otherwise specified in an applicable subpart of 40 CFR Part 63 or section in this regulation. If a startup, shutdown, or malfunction of one portion of an affected source does not affect the ability of particular emission points within other portions of the affected source to comply with the opacity and visible emission standards set forth in 40 CFR Part 63 or this regulation, then that emission point shall still be required to comply with the opacity and visible emission standards and other applicable requirements.

3.6.8.2 Methods for determining compliance.

3.6.8.2.1 The Department will determine compliance with opacity and visible emission standards in 40 CFR Part 63 or this regulation based on the results of the test method specified in an applicable subpart of 40 CFR Part 63 or section in this regulation. Whenever a COMS is required to be installed to determine compliance with numerical opacity emission standards in 40 CFR Part 63 or this regulation, compliance with opacity emission standards shall be determined by using the results from the COMS. Whenever an opacity emission test method is not specified, compliance with opacity emission standards shall be determined by conducting observations in accordance with Method 9 in Appendix A of 40 CFR Part 60 or the method specified in 3.6.8.7.2 of this regulation. Whenever a visible emission test method is not specified, compliance with visible emission standards in 40 CFR Part 63 or this regulation shall be determined by conducting observations in accordance with Method 22 in Appendix A of 40 CFR Part 60.

3.6.8.2.2 [Reserved]

3.6.8.2.3 If an affected source undergoes opacity or visible emission testing at startup to obtain an operating permit, the results of such testing may be used to demonstrate compliance with a relevant standard if-

3.6.8.2.3.1 The opacity or visible emission test was conducted within a reasonable amount of time before a performance test is required to be conducted under the relevant standard;

3.6.8.2.3.2 The opacity or visible emission test was conducted under representative operating conditions for the source;

3.6.8.2.3.3 The opacity or visible emission test was conducted and the resulting data were reduced using EPA-approved test methods and procedures, as specified in 3.7.5 of this regulation; and

3.6.8.2.3.4 The opacity or visible emission test was appropriately quality-assured, as specified in 3.7.3 of this regulation.

3.6.8.3 [Reserved]

3.6.8.4 Notification of opacity or visible emission observations.

The owner or operator of an affected source shall notify the Department in writing of the anticipated date for conducting opacity or visible emission observations in accordance with 3.9.6 of this regulation, if such observations are required for the source by a relevant standard.

3.6.8.5 Conduct of opacity or visible emission observations.

When a relevant standard under 40 CFR Part 63 or this regulation includes an opacity or visible emission standard, the owner or operator of an affected source shall comply with the following:

3.6.8.5.1 For the purpose of demonstrating initial compliance, opacity or visible emission observations shall be conducted concurrently with the initial performance test required in 3.7 of this regulation unless one of the following conditions applies:

3.6.8.5.1.1 If no performance test under 3.7 of this regulation is required, opacity or visible emission observations shall be conducted within 60 days after achieving the maximum production rate at which a new or reconstructed source will be operated, but not later than 120 days after initial startup of the source, or within 120 days after the effective date of the relevant standard in the case of new sources that start up before the standard’s effective date. If no performance test under 3.7 of this regulation is required, opacity or visible emission observations shall be conducted within 120 days after the compliance date for an existing or modified source or